Hollow fiber, dope solution composition for forming a hollow fiber, and method for manufacturing a hollow fiber using the same

A fiber and hollow technology, applied in the manufacture of hollow filaments, chemical instruments and methods, fiber treatment, etc., can solve problems such as difficult to obtain separation ability and permeability, and membrane performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

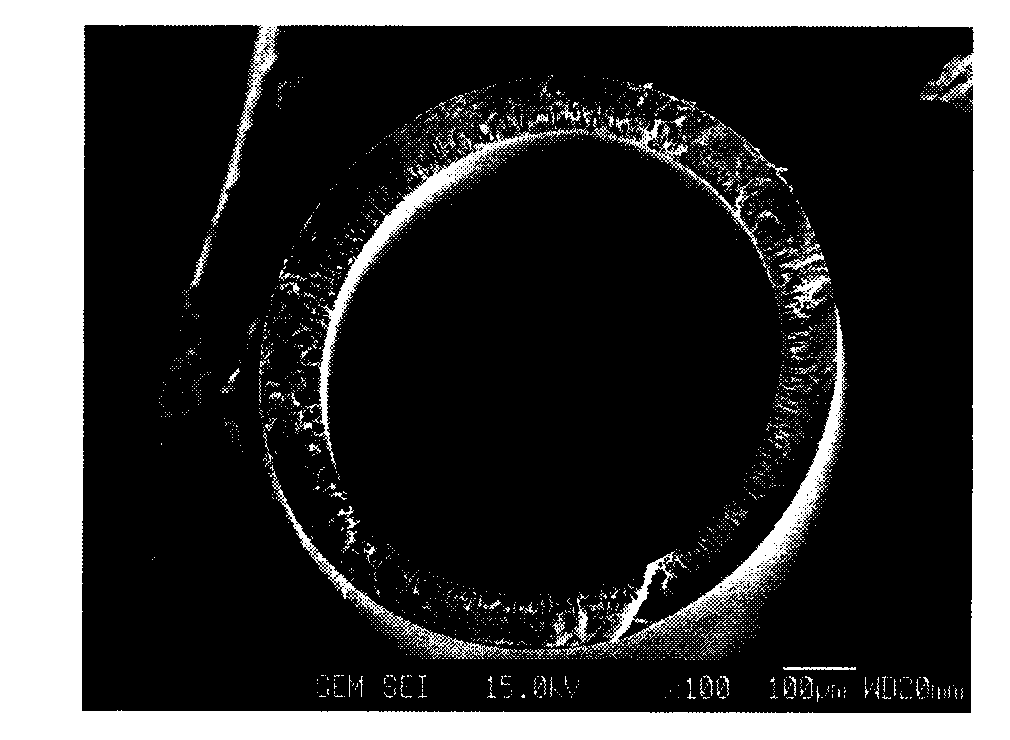

[0431] As shown in Reaction Scheme 5, a hollow fiber including polybenzoxazole represented by Chemical Formula 51 was prepared from a doping solution composition for forming a hollow fiber containing polyhydroxyimide.

[0432] [Reaction scheme 5]

[0433]

[0434] (1) Preparation of polyhydroxyimide

[0435] 36.6 g (0.1 mol) of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane was placed in a 1000 ml nitrogen purged reactor and N-methylpyrrolidone (NMP) solvent was added. The reactor was placed in an oil bath to constantly maintain the reaction temperature at -15°C. 44.4 g (0.1 mol) of 4,4'-(hexafluoroisopropene) diphthalic anhydride was slowly injected into the resulting solution. Then, the solution was allowed to react for about 4 hours to prepare a pale yellow viscous polyhydroxyamic acid solution.

[0436] 300 ml of toluene was added to the polyhydroxyamic acid solution. When the temperature of the reactor was raised to 150° C., polyhydroxyimide was obtained by perf...

Embodiment 2

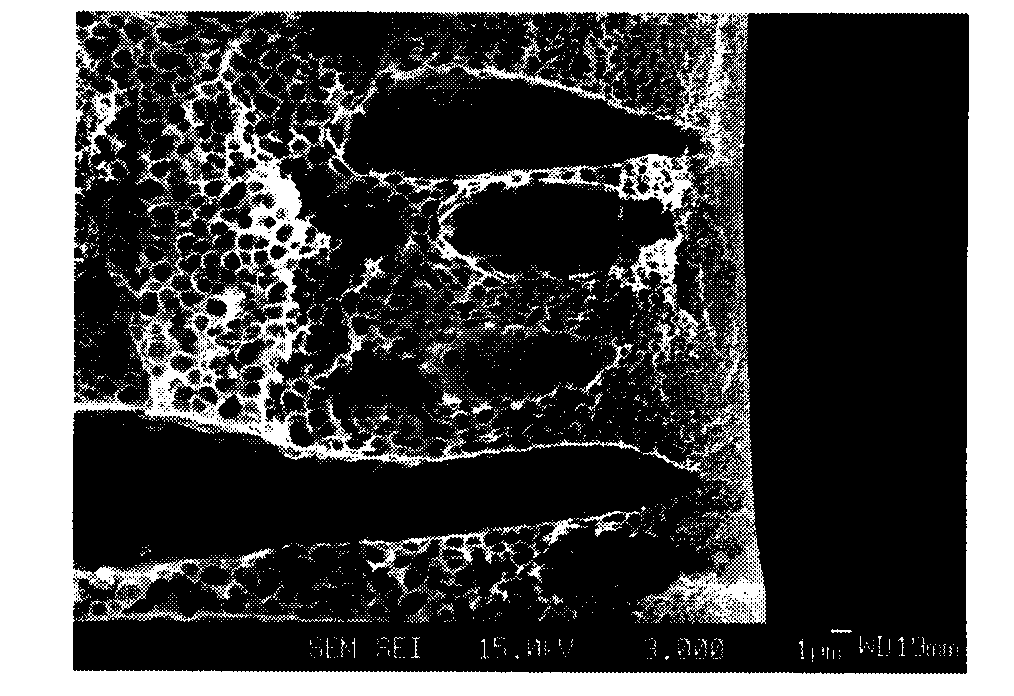

[0444] A hollow fiber comprising polybenzoxazole was prepared in the same manner as in Example 1, except that 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane and 4,4'-(hexafluoropropane Fluoroisopropylene) diphthalic anhydride was reacted at 180°C in a toluene-free solution for 24 hours to prepare polyimide.

[0445] The hollow fiber had a weight-average molecular weight of 9,240 and was identified as having 1620 cm which polyimide did not have as a result of FT-IR analysis. -1 (C=N), 1058cm -1 (C-N) frequency band, characteristic frequency band of polybenzoxazole. In addition, the hollow fiber has a free volume fraction of 0.34 and a interplanar spacing (d-spacing) of 680 pm.

[0446] The interplanar spacing (d-spacing) was determined by X-ray diffraction (XRD, CuKα rays, 10 to 40 degrees at 0.05 degree intervals, film samples).

Embodiment 3

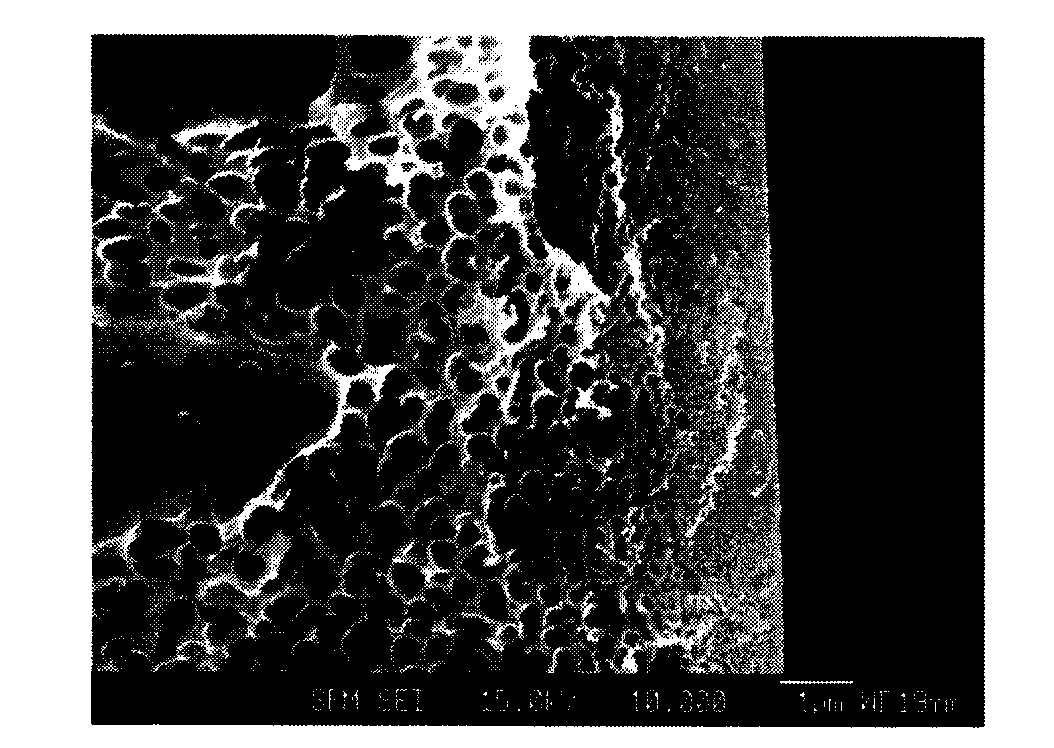

[0448] A hollow fiber including polybenzothiazole represented by the following Chemical Formula 52 was prepared through the following reaction.

[0449] [chemical formula 52]

[0450]

[0451] A hollow fiber including polybenzothiazole represented by the above Chemical Formula 52 was prepared according to the same method as in Example 1, except that by making 20.8 g (0.1 mol) of 2,5-diamino-1,4-benzenedithiol Dihydrochloride (2,5-diamino-1,4-benzenedithiol dihydrochloride) was used as a starting material to react with 44.4g (0.1mol) of 4,4'-(hexafluoroisopropylene) diphthalic anhydride to prepare SH) polyimide.

[0452] The hollow fiber had a weight average molecular weight of 32,290 and was identified as having a 1484 cm -1 (C-S), 1404cm -1 (C-S) Characteristic bands of polybenzothiazole. Furthermore, it has a free volume fraction of 0.28 and a interplanar spacing (d-spacing) of 640 pm.

[0453] The interplanar spacing (d-spacing) was determined by X-ray diffraction (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com