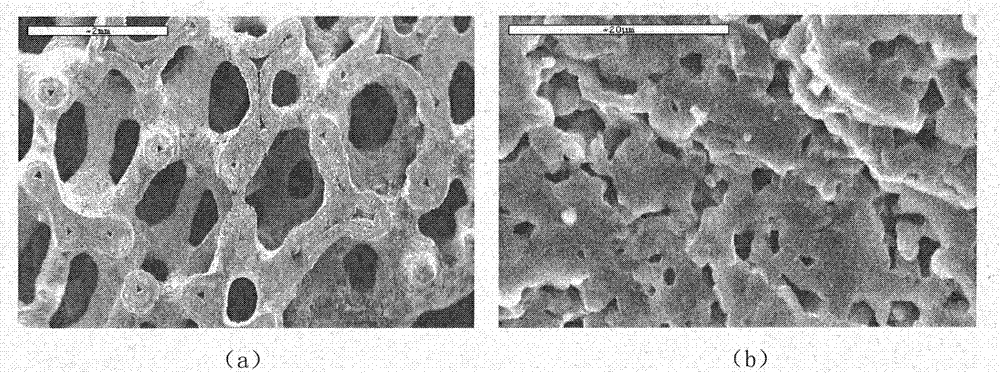

Double-scale silicon carbide foam ceramic material and preparation method thereof

A technology of foamed ceramics and silicon carbide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

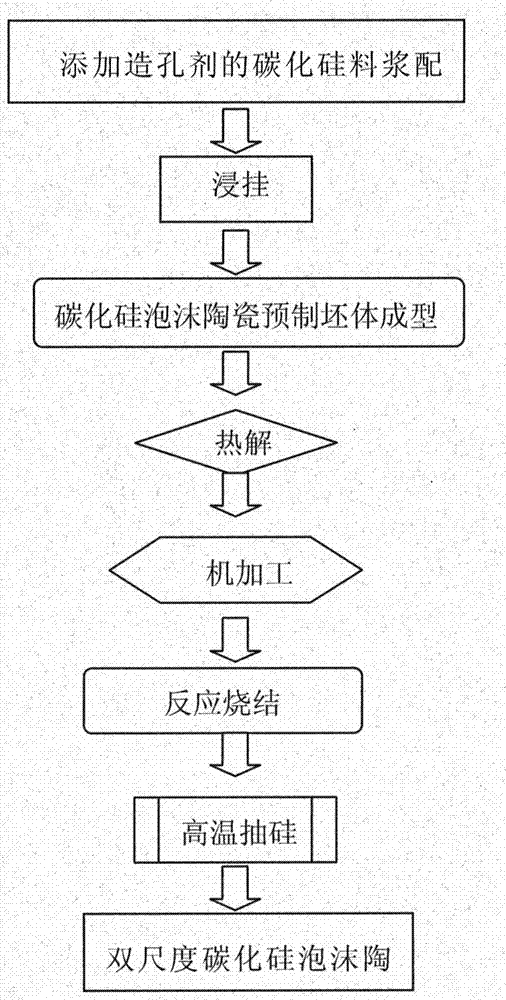

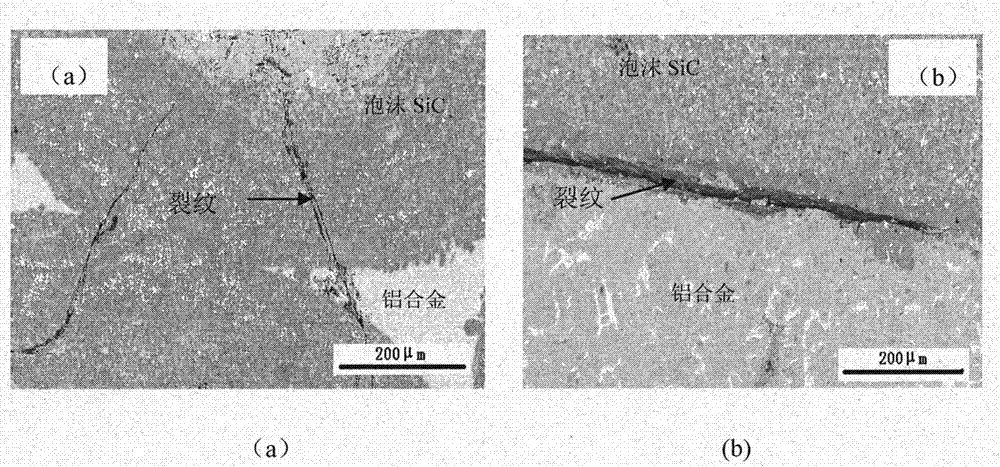

Method used

Image

Examples

Embodiment 1

[0048] SiC powder (1.5μm-10μm), silicon powder, epoxy resin, and industrial alcohol are prepared into a slurry according to a certain ratio. Table 1 shows the proportions of silicon carbide ceramic slurries containing different proportions of pore-forming agents (silicon powder W5-8).

[0049] Table 1 Proportion of silicon carbide ceramic slurry

[0050]

[0051] Prepare slurry according to different contents of pore-forming agent silicon powder in Table 1, select polyurethane foam with a pore size of 1.5 mm, cut the polyurethane foam into the required shape and size, immerse it evenly in the slurry, take it out and squeeze it out. Remove the excess slurry, remove the excess slurry by air blowing or centrifugation, heat the semi-cured, repeat several times until the volume fraction is 20%, and obtain the silicon carbide foam ceramic precursor; wherein, the semi-cured is heated at a temperature of 150 ° C. Curing time 30 minutes;

[0052] Under the protection of argon, it ...

Embodiment 2

[0057] The difference from Example 1 is:

[0058] Prepare a slurry with silicon carbide powder (200nm-500nm), silicon powder, phenolic resin, and industrial alcohol in a certain proportion. Table 1 is the proportion of silicon carbide ceramic slurry containing different proportions of pore-forming agents (silicon powder W5-8). Prepare slurry according to 1# and 4# formulas in Table 1, select polyurethane foam with pore diameter of 1.5mm to soak and hang slurry, and hang slurry to volume fraction of 20% ( First use the 1# formula to hang the slurry to a volume fraction of 15%, and then use the 4# formula to hang the slurry to a volume fraction of 20%). Under the protection of argon, it is pyrolyzed to form a carbon skeleton. The heating rate is 3°C per minute, the temperature is raised to 800°C, and the temperature is kept for 0.5 hours. After pyrolysis, infiltration reaction sintering is carried out, the reaction temperature is 1780°C, the heating rate is 10°C / min, and the t...

Embodiment 3

[0062] The difference from Example 1 is:

[0063] The silicon carbide powder (10μm-15μm), silicon powder, phenolic resin, and industrial alcohol are prepared into a slurry according to a certain ratio. Table 1 shows the proportions of silicon carbide ceramic slurries containing different proportions of pore-forming agents (silicon powder W5-8). Prepare the slurry according to the 1# and 5# formulas in Table 1, select the polyurethane foam with a pore size of 1.5mm to soak the slurry, first hang the slurry according to the 5# formula to a volume fraction of 10%, and then press the 1# formula to hang the slurry to 20% volume fraction. Under the protection of argon, it is pyrolyzed to form a carbon skeleton. The heating rate is 3°C per minute, the temperature is raised to 1000°C, and the temperature is kept for 0.5 hours. After pyrolysis, infiltration reaction sintering is carried out, the reaction temperature is 1680°C, the heating rate is 5°C / min, and the temperature is maint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com