Crystal growth inhibitor for fats and oils

一种生长抑制剂、抑制剂的技术,应用在食用油/脂肪、产生脂肪、利用添加剂保藏脂肪物质等方向,能够解决液体油脂难商品化等问题,达到商品价值提高、效果持久、抑制结晶生长的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1( Synthetic example 1

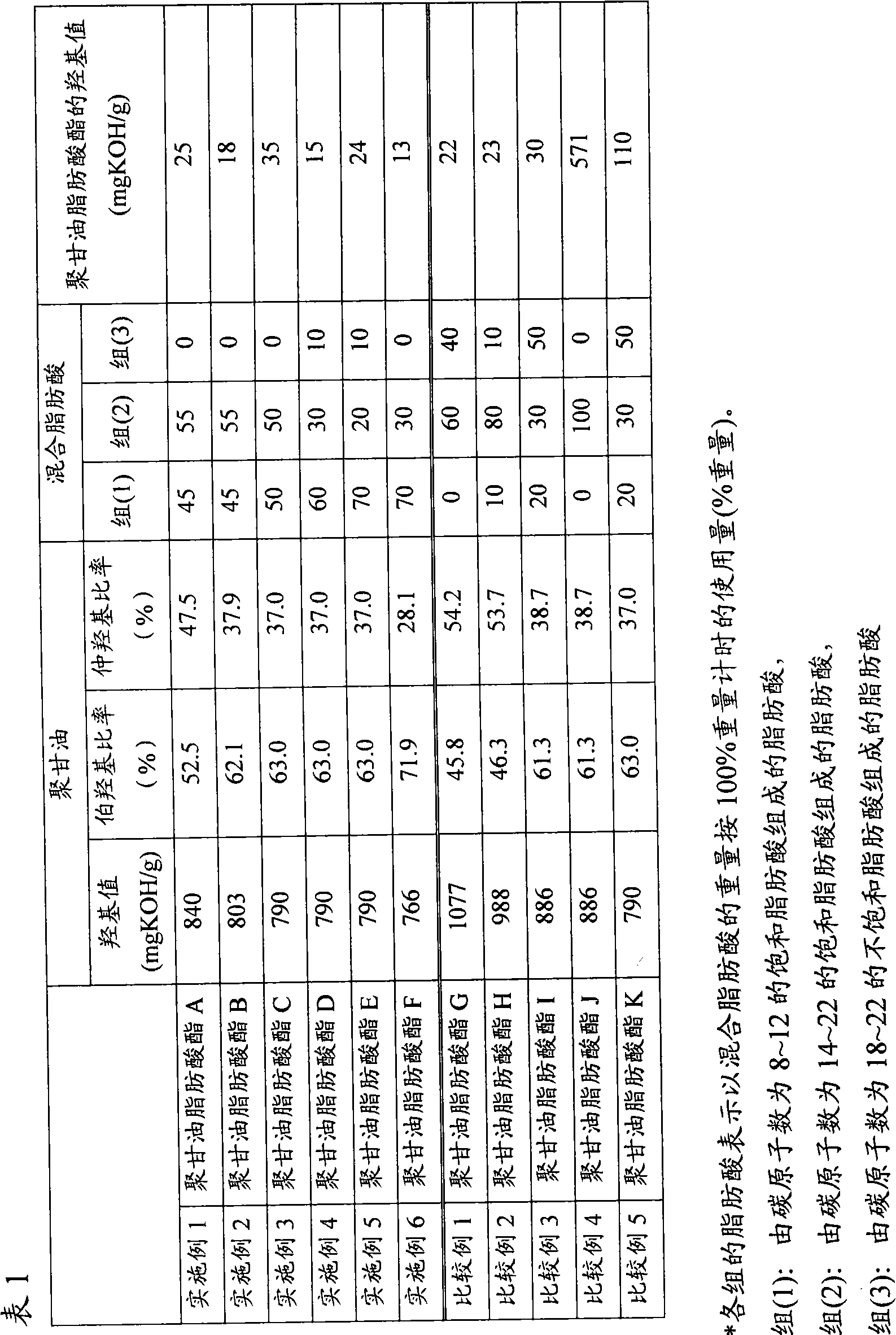

[0063] Add 200 g of polyglycerol (GREAT OIL (Great Oil) KT-1) made by Sun Chemical Co., Ltd. and 600 mL of pyridine. To this was added 370 g of chlorotrityl (manufactured by Wako Pure Chemical Industries, Ltd.), a reagent that selectively reacts with primary hydroxyl groups, stirred at 100° C. for 1 hour, and further stirred for 24 hours after cooling to room temperature (25° C.). Then, the reaction liquid was distilled off under reduced pressure to remove most of pyridine. 800 mL of water was added to the prepared reactant, transferred to a separatory funnel, and extracted with 400 mL of ethyl acetate (extraction times: 3 times). The ethyl acetate layers were combined and concentrated, and 156 g of the resulting residue and 300 g of acetic acid were added to a three-necked flask equipped with a thermometer, Dimroth and a stirring device, heated to reflux at 120° C. for 8 hours, and purified after the triphenylmethyl group was eliminated. Polyglycerol A was prepared. The hy...

Embodiment 2( Synthetic example 2

[0066] Hydroxyl value Purified polyglycerol B of 803 mgKOH / g, primary hydroxyl group ratio of 62.1%, and secondary hydroxyl group ratio of 37.9%. Then, 60 g of the prepared polyglycerol B, 180 g of the mixed fatty acids shown in Table 1, and 0.1 g of sodium hydroxide were added to a 300 mL four-necked flask, and the resulting water was removed at 250° C. under a nitrogen stream. The reaction of the obtained polyglycerol fatty acid ester B with a hydroxyl value of 18 mgKOH / g.

Embodiment 3( Synthetic example 3

[0068]Hydroxyl value Purified polyglycerol C with 790 mgKOH / g, a primary hydroxyl group ratio of 63.0%, and a secondary hydroxyl group ratio of 37.0%. Then, 64.8g of the prepared polyglycerol C, 175.2g of the mixed fatty acids shown in Table 1, 0.1g of sodium hydroxide were added to a 300mL four-necked flask, and the resulting water was removed at 250 ℃ to react to obtain polyglycerol fatty acid ester C with a hydroxyl value of 35 mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com