Chip type oxygen sensor and preparation method thereof

An oxygen sensor and chip technology, which is applied in the field of chip oxygen sensor and its preparation, can solve the problems of low sensitivity, poor thermal shock resistance, and short service life of the oxygen sensor, and achieve improved sensitivity, high thermal shock resistance, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

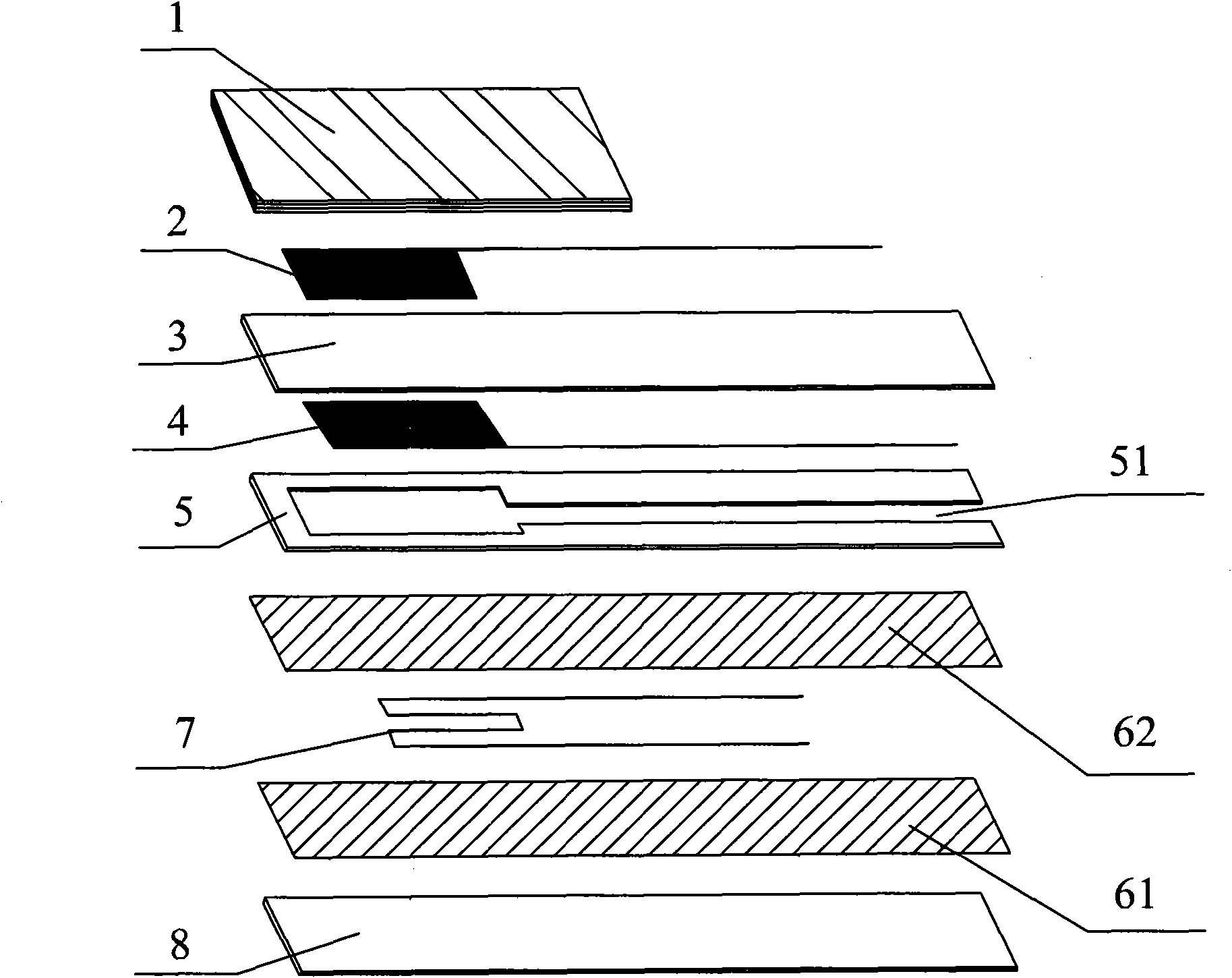

[0028] The present invention also provides a preparation method of a chip oxygen sensor, comprising the following steps:

[0029] 1) Coating insulating layer slurry, electrode slurry, and insulating layer slurry on the heater substrate, drying, forming an insulating layer on the heater substrate, and obtaining the first sheet; getting a reference gas substrate as second sheet;

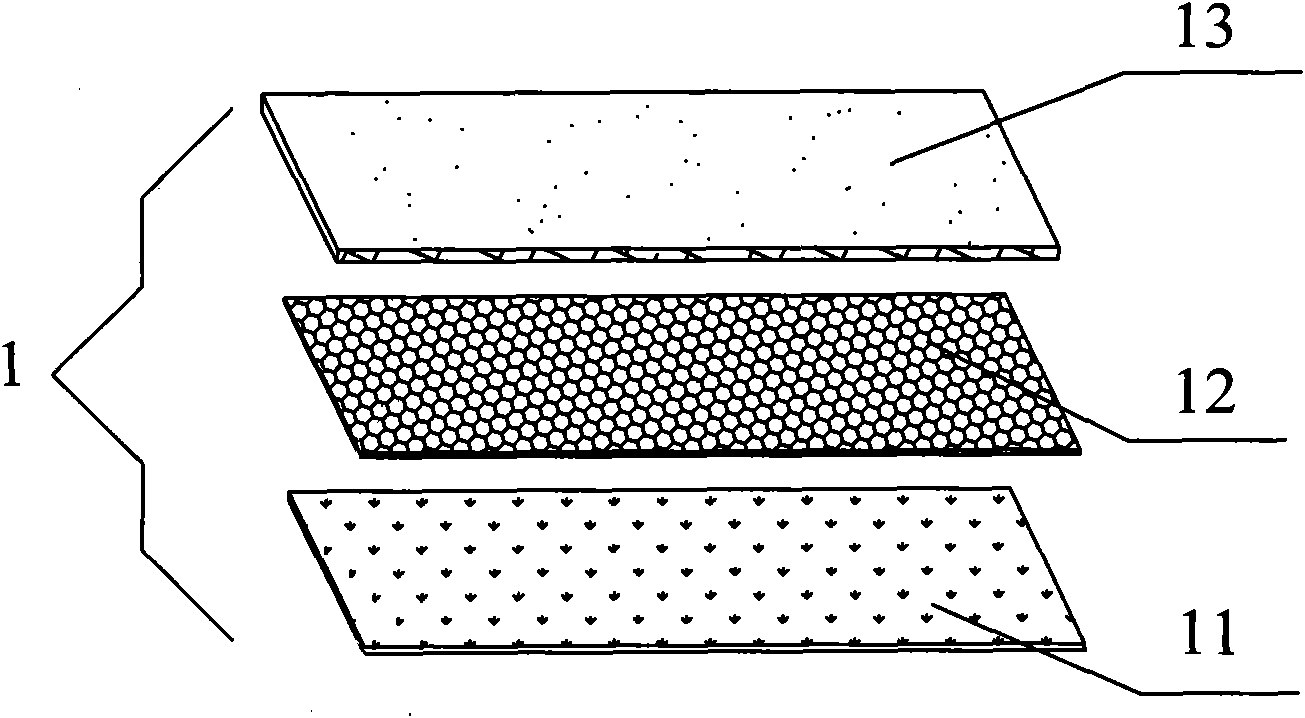

[0030] 2) screen printing transition layer slurry on the oxygen measuring electrolyte layer to form a transition layer; screen printing porous layer slurry to form a porous layer on the transition layer; obtain the third sheet;

[0031] 3) One side of the insulating layer of the first sheet faces up, and one side of the porous layer of the third sheet faces up, and the first sheet, the second sheet, and the third sheet are stacked sequentially from bottom to top, Co-fire the stack at 1300-1600°C; obtain a co-fired body of the chip oxygen sensor;

[0032] 4) On the porous layer of the chip-type oxygen...

Embodiment 1

[0051] (1) The heater substrate, the reference gas substrate blank, and the zirconia electrolyte matrix are prepared by casting technology; the insulating layer, the heating electrode, and the insulating layer are successively coated on the heater substrate by a screen printing process. The heater substrate; the reference gas substrate blank adopts laser cutting to produce air passages to obtain the reference gas substrate; the upper electrodes are printed on both sides of the zirconia electrolyte substrate to obtain the oxygen measuring electrolyte layer.

[0052] (2) Raw material preparation: the particle size of the powder material is less than 2 μm, and the median diameter is 0.5-1.2 μm:

[0053] Transition layer: Transition layer powder material: Y-ZrO 2 92 parts by weight, MgAl 2 o 4 8 parts by weight; pore-forming agent (particle diameter<2 μm, median diameter: 0.6 μm): 0.4 parts by weight of starch, 0.8 parts by weight of high polymer ultrafine polyvinyl chloride, and ...

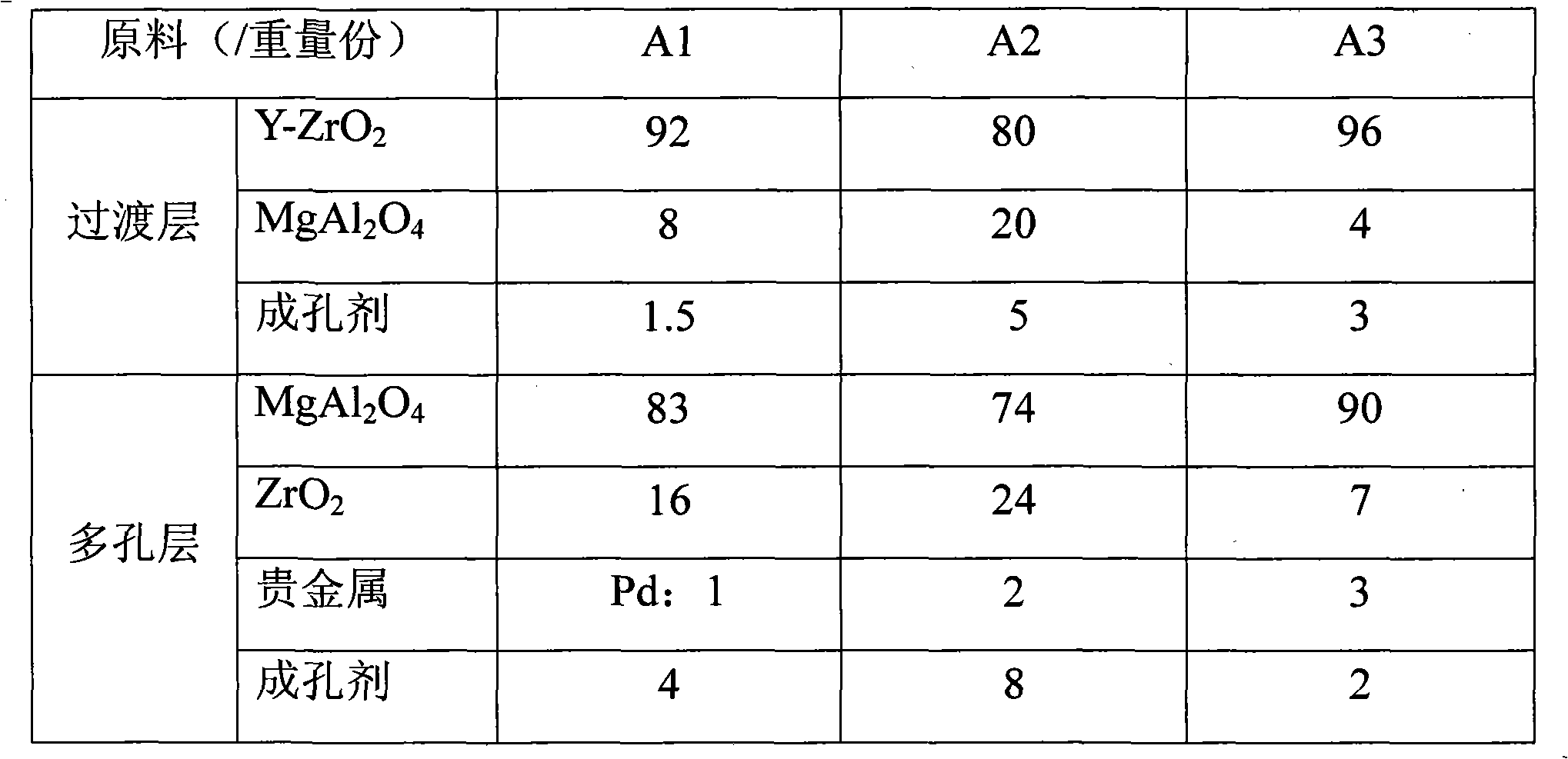

Embodiment 2-3

[0062] The same method as in Example 1 was used to prepare the chip oxygen sensor of this example, except that in step (2), the amount of slurry used and the components of the slurry were different, see Table 1 for details.

[0063] Through the above steps, the obtained chip oxygen sensors are sequentially recorded as A2-A3.

[0064] Table 1

[0065]

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com