Self-assembly preparation method and application of solid/liquid interface of graphene oxide hydrogel

A technology of graphene hydrogel and graphene airgel, which is applied in the self-assembly of solid-liquid interface of graphene oxide hydrogel, in the field of graphene oxide hydrogel, can solve problems such as energy consumption and achieve good mechanical properties performance, good electrochemical energy storage performance, simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

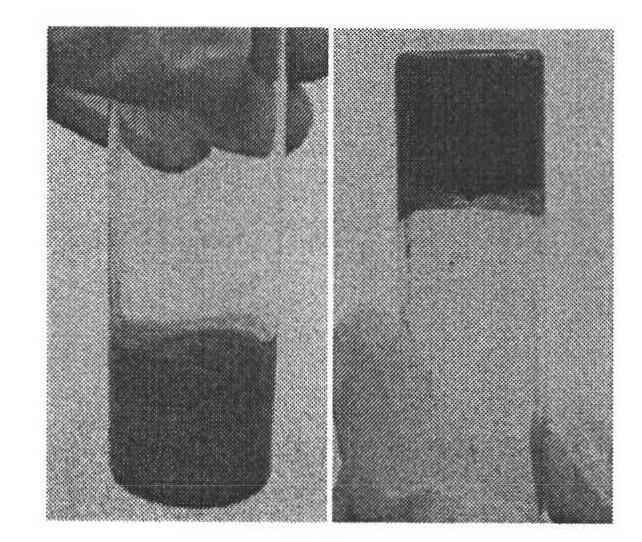

Embodiment 1

[0015] The aluminum foil is electrochemically oxidized by a classic two-step anodic oxidation method to obtain a porous anodized aluminum film with a pore size distribution of 10-200nm. The specific process is to clean the aluminum foil with ultrasonic vibration in acetone and ethanol solvents for 10 minutes, and then soak it in 1mol / L sodium hydroxide to remove the natural oxide layer on the surface. Then electrochemical polishing was carried out in a solution of perchloric acid and ethanol with a volume ratio of 1:1, and the voltage was set at 12 V until the surface was mirror-smooth. At room temperature, in a sulfuric acid electrolyte of 0.3-1.2mol / L, with a voltage of 15-25V, another aluminum sheet with a larger area is used as a counter electrode to perform anodic oxidation treatment once, and then use a mass fraction of 1.8% The mixed solution of chromic acid and 6.0% phosphoric acid is soaked to remove the film. Carry out the second anodic oxidation again, and the oxid...

Embodiment 2

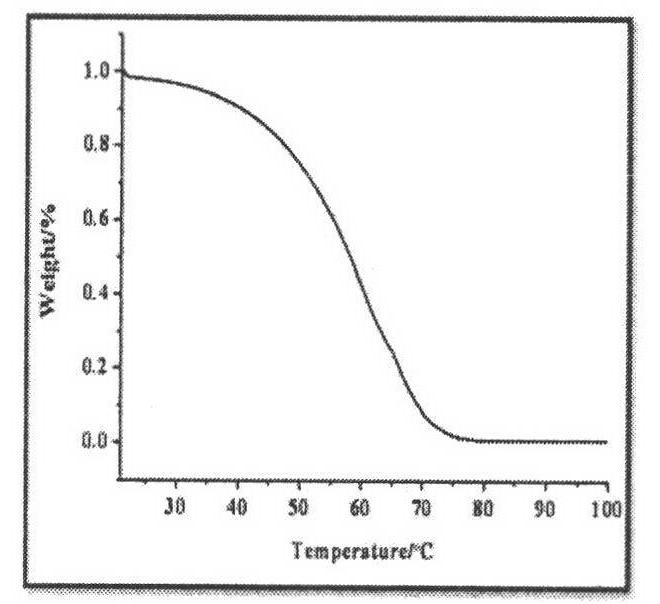

[0020] Present embodiment is identical with embodiment 1 process, just changes the add-on of graphite oxide: becomes 560mg by 80mg. The volume of the obtained graphene oxide hydrogel remained unchanged, but the water content of the hydrogel was reduced by 0.1%.

Embodiment 3

[0022] The process of this embodiment is the same as that of Embodiment 1, except that the ultrasonic power is changed from 120W to 300W. This process only changes the size of the graphene oxide sheet in the graphene oxide aqueous solution, and the volume and water content of the obtained graphene oxide hydrogel remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com