Composite organic and inorganic polymeric flocculant and preparation process and application of composite organic and inorganic polymeric flocculant

An inorganic polymer and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of unsatisfactory wastewater treatment effect, achieve ideal effect, simple production process, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

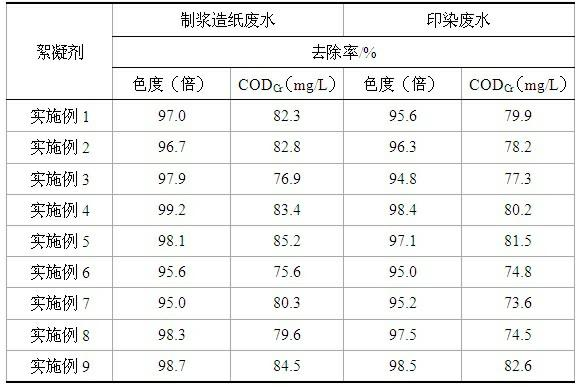

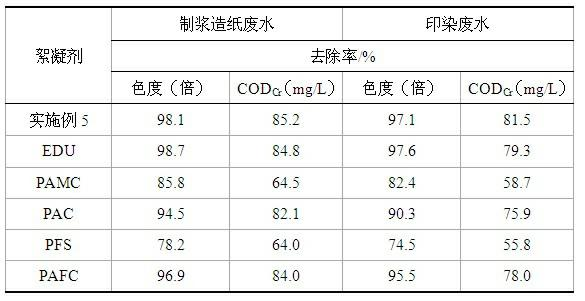

Examples

Embodiment 1

[0056] 1. The raw materials and consumption thereof of the present embodiment:

[0057] Dimethylamine: 60 kg

[0058] Urea: 40kg

[0059] Epichlorohydrin: 200 kg

[0060] Catalyst (sodium hydroxide): 10 kg

[0061] Cross-linking agent (1,2-ethylenediamine): 90 kg

[0062] Solvent (ammonium chloride): 10 kg

[0063] Additive (polyacrylic acid): 5 kg

[0064] Aluminum salt (aluminum chloride): 180 kg

[0065] Water: 405 kg

[0066] 2. the process steps and process parameters of the present embodiment:

[0067] Add 40 kg of urea, 60 kg of dimethylamine, 10 kg of sodium hydroxide and water to the reactor in sequence at 50°C, stir until the urea is completely dissolved and mixed evenly, then add 200 kg of epichlorohydrin dropwise, add dropwise After completion, slowly raise the temperature of the reaction system to 75°C, add 90 kg of 1,2-ethylenediamine, react for 4 hours, then add 10 kg of ammonium chloride and 5 kg of polyacrylic acid with an average molecular weight of 5...

Embodiment 2

[0069] 1. The raw materials and consumption thereof of the present embodiment:

[0070] Dimethylamine: 130 kg

[0071] Urea: 85 kg

[0072] Epichlorohydrin: 216 kg

[0073] Catalyst (potassium hydroxide): 4 kg

[0074] Cross-linking agent (1,2-ethylenediamine / 1,3-propylenediamine, mass ratio 1:2): 60 kg

[0075] Solvent (ammonium chloride / ammonium sulfate, mass ratio 2:1): 24 kg

[0076] Additive (polyacrylic acid): 6 kg

[0077] Aluminum salt (aluminum sulfate): 120 kg

[0078] Water: 355 kg

[0079] 2. the process steps and process parameters of the present embodiment:

[0080] Add 85 kg of urea, 130 kg of dimethylamine, 4 kg of potassium hydroxide and a certain amount of water to the reactor in sequence at 55°C, stir until the urea is completely dissolved and mix evenly, then add 216 kg of epichlorohydrin dropwise, After the dropwise addition, slowly raise the temperature of the reaction system to 80°C, add 60 kg of 1,2-ethylenediamine / 1,3-propylenediamine mixture, ...

Embodiment 3

[0082] 1. The raw materials and consumption thereof of the present embodiment:

[0083] Dimethylamine: 78 kg

[0084] Urea: 102 kg

[0085] Epichlorohydrin: 126 kg

[0086] Catalyst (sodium carbonate): 8 kg

[0087] Cross-linking agent (1,4-butylene diamine): 52 kg

[0088] Solvent (ammonium nitrate): 16 kg

[0089] Additive (polyacrylic acid): 8 kg

[0090] Aluminum salt (potassium aluminum sulfate): 160 kg

[0091] Water: 450kg

[0092] 2. the process steps and process parameters of the present embodiment:

[0093] Add 102 kg of urea, 78 kg of dimethylamine, 8 kg of sodium carbonate and a certain amount of water to the reactor in sequence at 60°C, stir until the urea is completely dissolved and mix well, then add 126 kg of epichlorohydrin dropwise, After the addition, slowly raise the temperature of the reaction system to 85°C, add 52 kg of 1,4-butylene diamine, react for 5 hours, then add 16 kg of ammonium nitrate and 8 kg of polyacrylic acid with an average molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com