Aqueous rusted anti-corrosive coating and preparation method thereof

A rust and anti-corrosion, coating technology, used in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of solvent pollution of the construction environment, volatile organic compounds easy to pollute the environment, poor rust conversion ability, etc. Firm, dense and uniform, beneficial to environmental protection, and the effect of increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

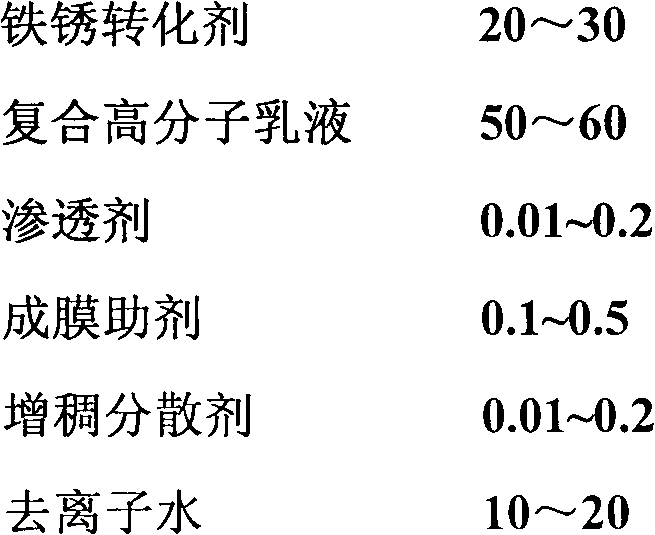

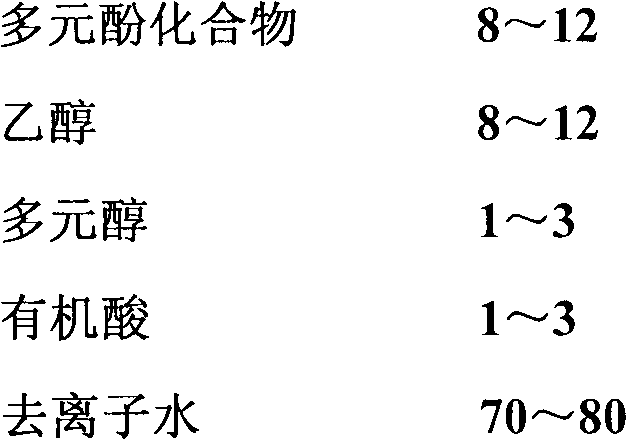

Method used

Image

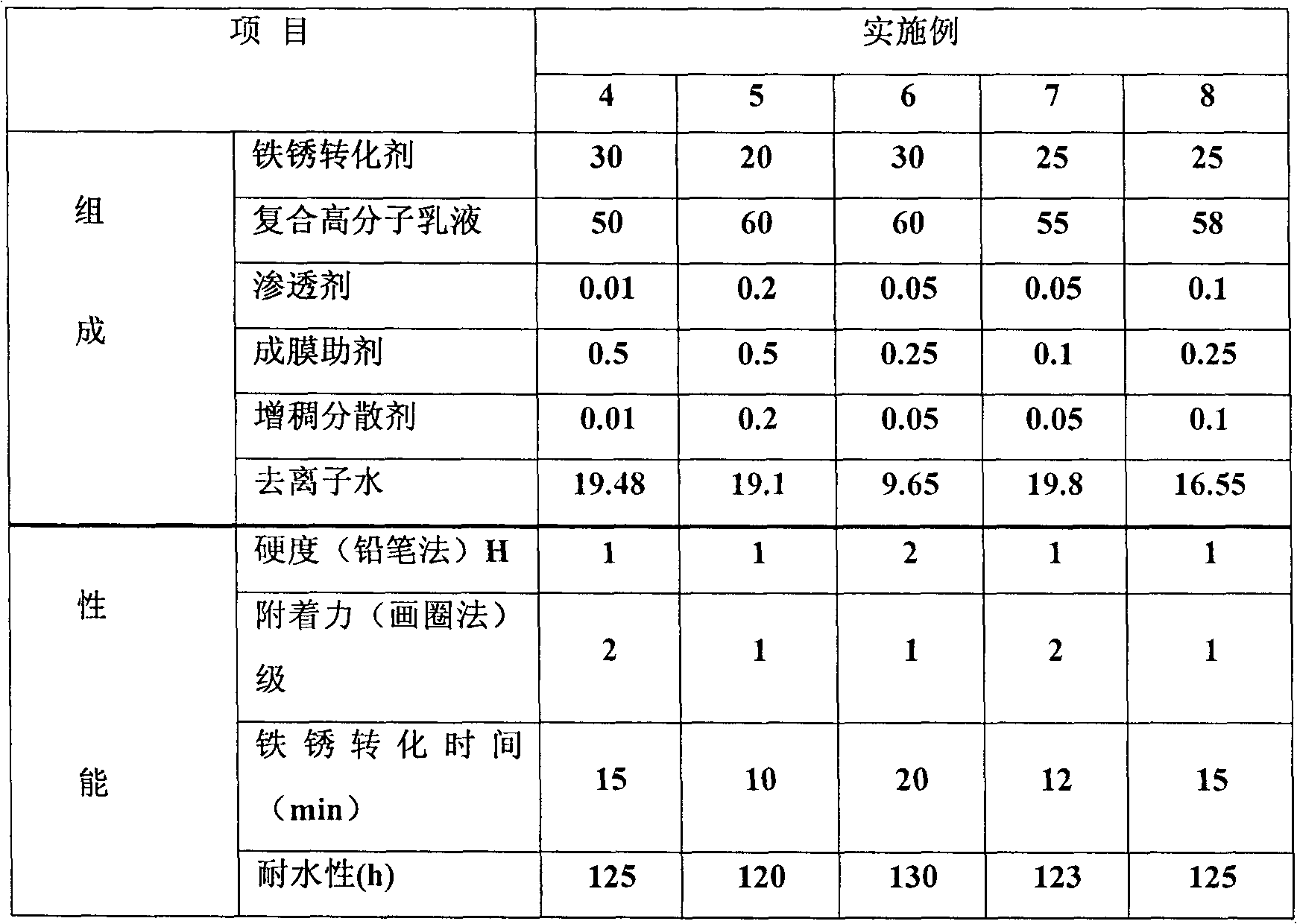

Examples

Embodiment 1

[0026] (1) Preparation of rust converting agent

[0027] Add 10 grams of ethanol and 10 grams of deionized water in the flask and mix well, add 8 grams of pyrogallol and 2 grams of hydroquinone to dissolve it completely, then add 2 grams of glycerol, 2 grams of citric acid and 60 gram of deionized water, stirred evenly, is the rust conversion agent;

[0028] (2) Preparation of composite polymer emulsion

[0029] Add 70 grams of styrene-acrylic emulsion and 10 grams of epoxy emulsion to the flask and stir evenly, then slowly add 20 grams of urea-formaldehyde resin glue, and stir rapidly for 10-20 minutes to form a composite polymer emulsion;

[0030] (3) Preparation of target product energy-saving and environment-friendly water-based anti-corrosion coating with rust

[0031] Add 60 grams of composite polymer emulsion and 25 grams of rust conversion agent in the flask, stir evenly, then add 0.1 gram of glycerol and 0.3 gram of ethylene glycol ethyl ether in batches, continue t...

Embodiment 2

[0039] (1) Preparation of rust converting agent

[0040] Add 8 grams of ethanol and 8 grams of deionized water into the flask, mix well, add 10 grams of pyrogallol and 2 grams of hydroquinone to dissolve completely, then add 1 gram of polyol, 1 gram of citric acid and 65 grams of Deionized water, stirred evenly, is the rust conversion agent;

[0041] (2) Preparation of target product energy-saving and environment-friendly water-based anti-corrosion coating with rust

[0042] Add 60 grams of composite polymer emulsion and 25 grams of rust conversion agent in the flask, stir evenly, then add 0.1 gram of glycerol and 0.3 gram of ethylene glycol ethyl ether in batches, continue to stir, and finally slowly add 0.1 gram of carboxymethyl cellulose and 14.5 grams of deionized water mixed solution was heated up to 40°C-50°C, stirred for 20-30 minutes to obtain the target product water-based anti-corrosion coating with rust.

[0043] The energy-saving and environment-friendly water-ba...

Embodiment 3

[0049] (1) Preparation of rust converting agent

[0050] Add 12 grams of ethanol and 12 grams of deionized water to the flask and mix well, add 7 grams of pyrogallol and 2 grams of hydroquinone to dissolve completely, then add 1 gram of sorbitol, 1 gram of tartaric acid and 65 grams of Deionized water, stirred evenly, is the rust conversion agent;

[0051] (2) Preparation of target product water-based anti-corrosion coating with rust

[0052] Add 60 grams of composite polymer emulsion and 25 grams of rust conversion agent into the flask, stir evenly, then add 0.1 grams of glycerol and 0.3 grams of ethylene glycol butyl ether in batches, continue stirring, and finally slowly add 0.1 grams of carboxymethyl cellulose After mixing with 14.5 grams of deionized water, the temperature was raised to 40°C-50°C, and stirred for 20-30 minutes to obtain the target product water-based anti-corrosion coating with rust.

[0053] The energy-saving and environment-friendly water-based rust-res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com