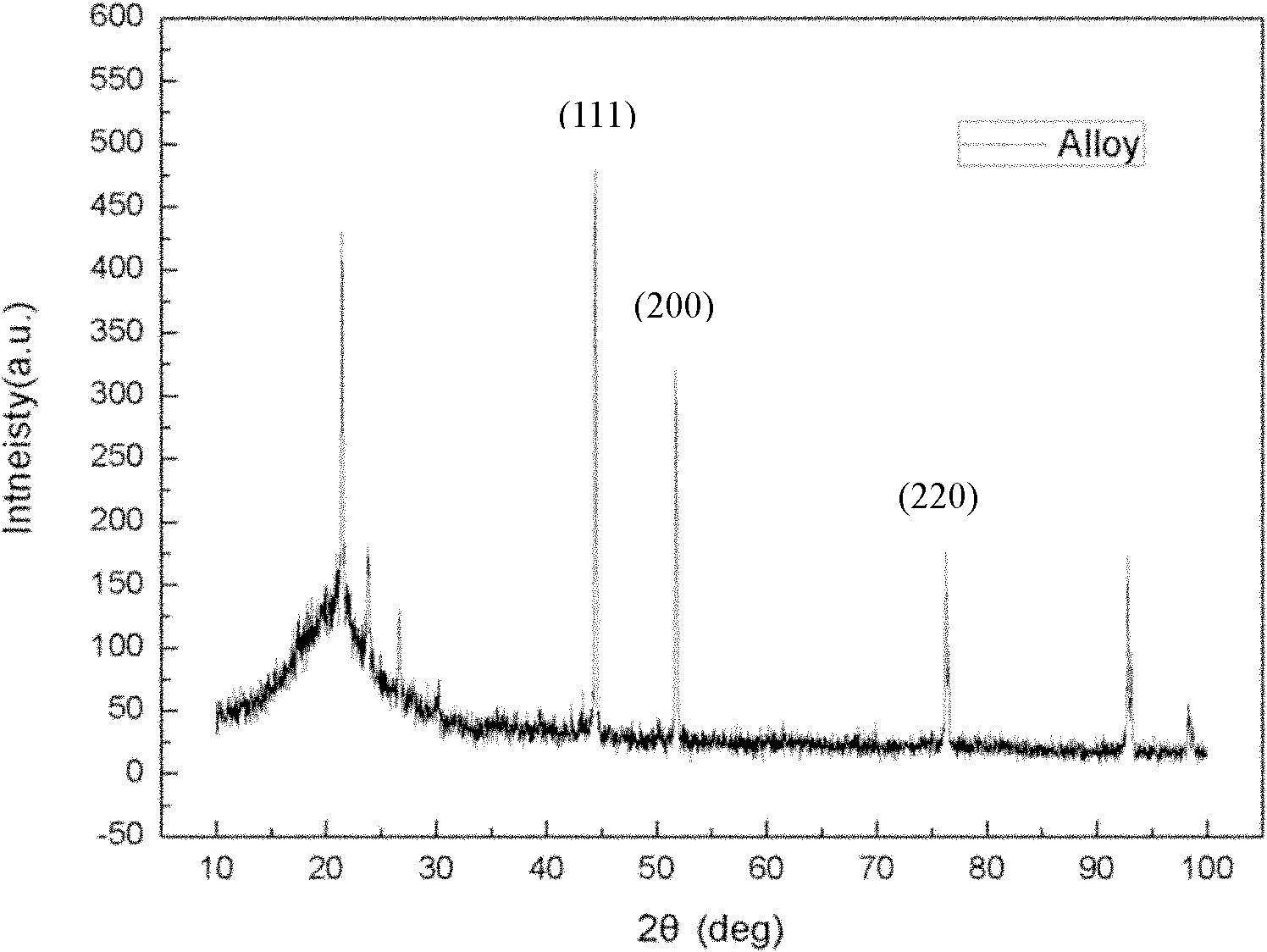

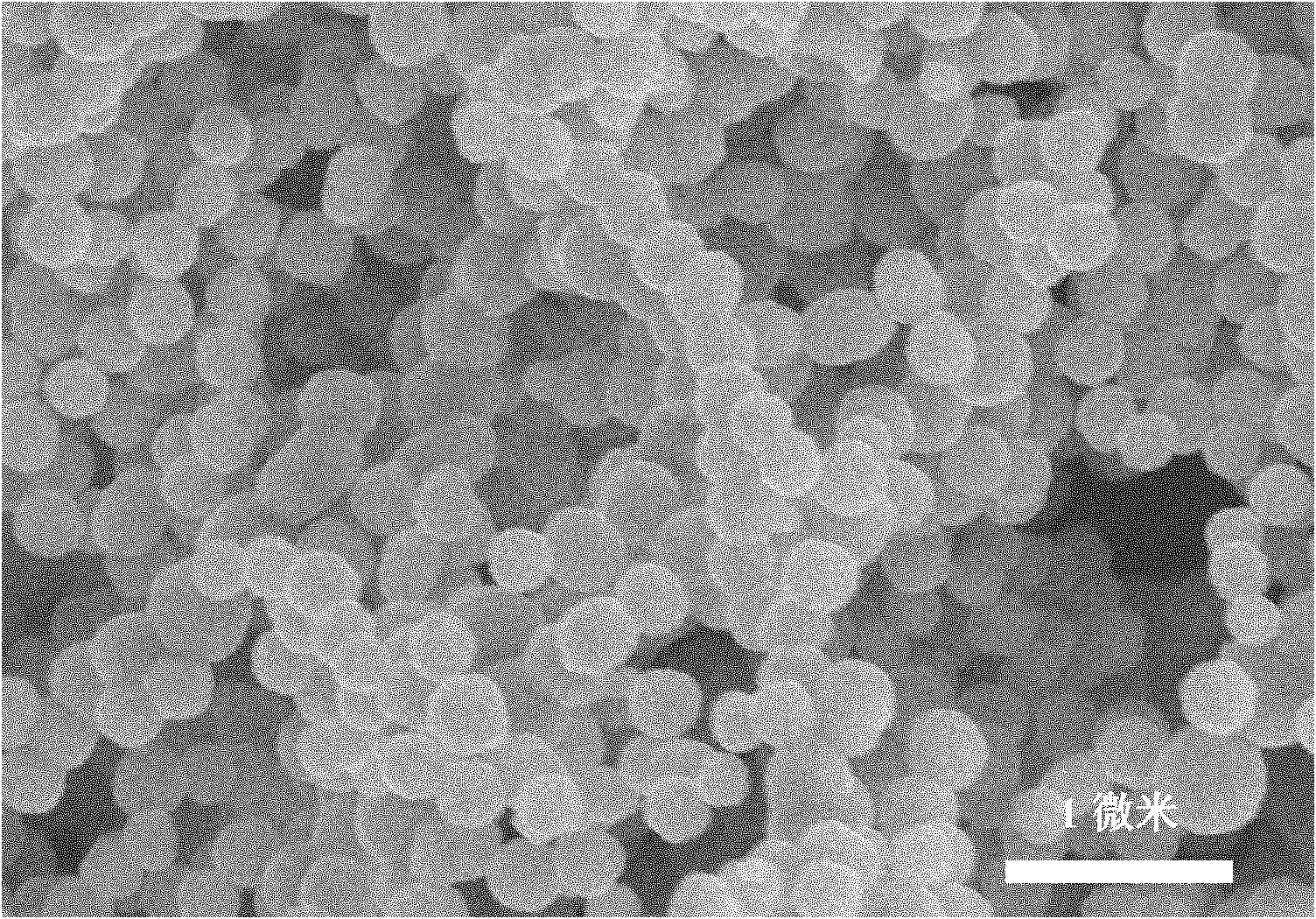

Method for preparing micro-nano hole cobalt nickel alloy

A micro-nanopore, cobalt-nickel alloy technology is applied in the preparation of micro-nanoporous cobalt-nickel alloy materials, and in the field of preparing a cobalt-nickel alloy material with micro-nanopores, which can solve the problem that it cannot be used as a structural material and is difficult to satisfy at the same time. Due to the various needs of the aircraft, the synthesis method is easy to control, light in weight, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] ① Preparation of nickel salt ethylene glycol solution: 0.1188g nickel chloride hexahydrate (NiCl 2 ·6H 2 (2) and 1.0933g cetyltrimethylammonium bromide (CTAB) are dissolved in 50ml ethylene glycol (EG), stir 2h at room temperature and nickel chloride is fully dissolved in ethylene glycol, obtain nickel chloride Ethylene glycol solution.

[0033] ② Preparation of cobalt salt glycol solution: 0.1095g cobalt chloride hexahydrate (CoCl 2 ·6H 2 (2) and 1.0933g cetyltrimethylammonium bromide (CTAB) are dissolved in 50ml ethylene glycol (EG), and stirring 2h at room temperature makes cobaltous chloride fully dissolved in ethylene glycol, obtains cobaltous chloride Ethylene glycol solution.

[0034] ③Preparation of nickel nanoparticles: under the condition of magnetic stirring, slowly heat the nickel salt ethylene glycol solution, the solution is heated up to 120 °C, and then, drop 2mL of hydrazine hydrate (N 2 h 4 · H2O, 80%), mix well. Keep warm for 2 hours. The final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com