Method for synthesizing silicon nitride nanorod crystalline material at low temperature by solvothermal method

A nanorod-shaped, solvothermal method, applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of low purity, difficult to repeat the reaction process, poor crystallization of materials, etc., achieve simple experimental equipment, overcome reaction High temperature, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

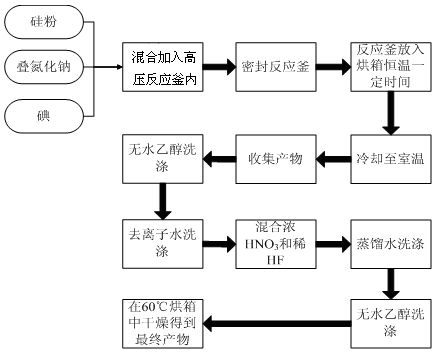

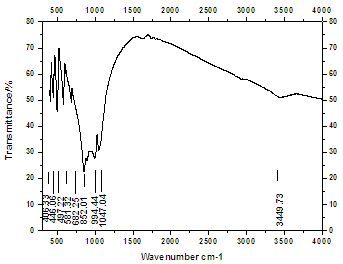

[0036] Add 0.3g of silicon powder, 3g of sodium azide and 8g of iodine to a 30ml high-pressure stainless steel reaction kettle, stir evenly with a glass rod; seal the reaction kettle and place it in an oven, heat it to 250°C, keep it at this temperature and continue After heating for 15 hours, cool to room temperature naturally, and collect the product after the reaction. The product is a solid powder; the collected product is washed with absolute ethanol, deionized water, and HNO. 3 And HF (v / v=3:1) mixed solution, washed with distilled water; finally dehydrated product with absolute ethanol. The prepared samples were tested by XRD, FITR, SEM and TEM, and the results showed that the product was a nanorod-shaped silicon nitride crystal.

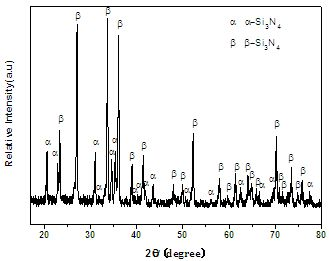

[0037] figure 2 This is the XRD pattern of the synthesized silicon nitride nanorod crystals in Example 1. by figure 2 It can be seen that the obtained product is silicon nitride with a mixed phase of α and β, and no diffraction peaks of other ...

Embodiment 2

[0039] The process flow of this embodiment is the same as that of Embodiment 1, except that the heating temperature in this embodiment after the reactor is sealed and placed in the oven is 200°C. The sample prepared in this embodiment can achieve the same technical effect as the embodiment 1. Image 6 SEM morphology of the synthesized silicon nitride nanorod crystals in Example 2. by Image 6 It can be clearly seen that the product is a rod-shaped crystal with a diameter of about 200 nanometers. The surface of the crystal rod is smooth and regular, and the thickness is relatively uniform.

Embodiment 3

[0041] The process flow of this embodiment is the same as that of Embodiment 1, except that the heating temperature in this embodiment after the reactor is sealed and placed in the oven is 220°C. The sample prepared in this embodiment can achieve the same technical effect as the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com