Zinc oxide micro/nano composite structure array film and preparation method thereof

A composite structure, zinc oxide nanorod technology, applied in the field of zinc oxide micro/nano composite structure array film and its preparation, can solve the problem that the metal layer cannot have the physical and chemical properties of the zinc oxide layer, the limited superior performance and the unique use, Can not obtain zinc oxide array film and other problems, to achieve the effect of high stability, high production efficiency, high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The concrete steps of preparation are:

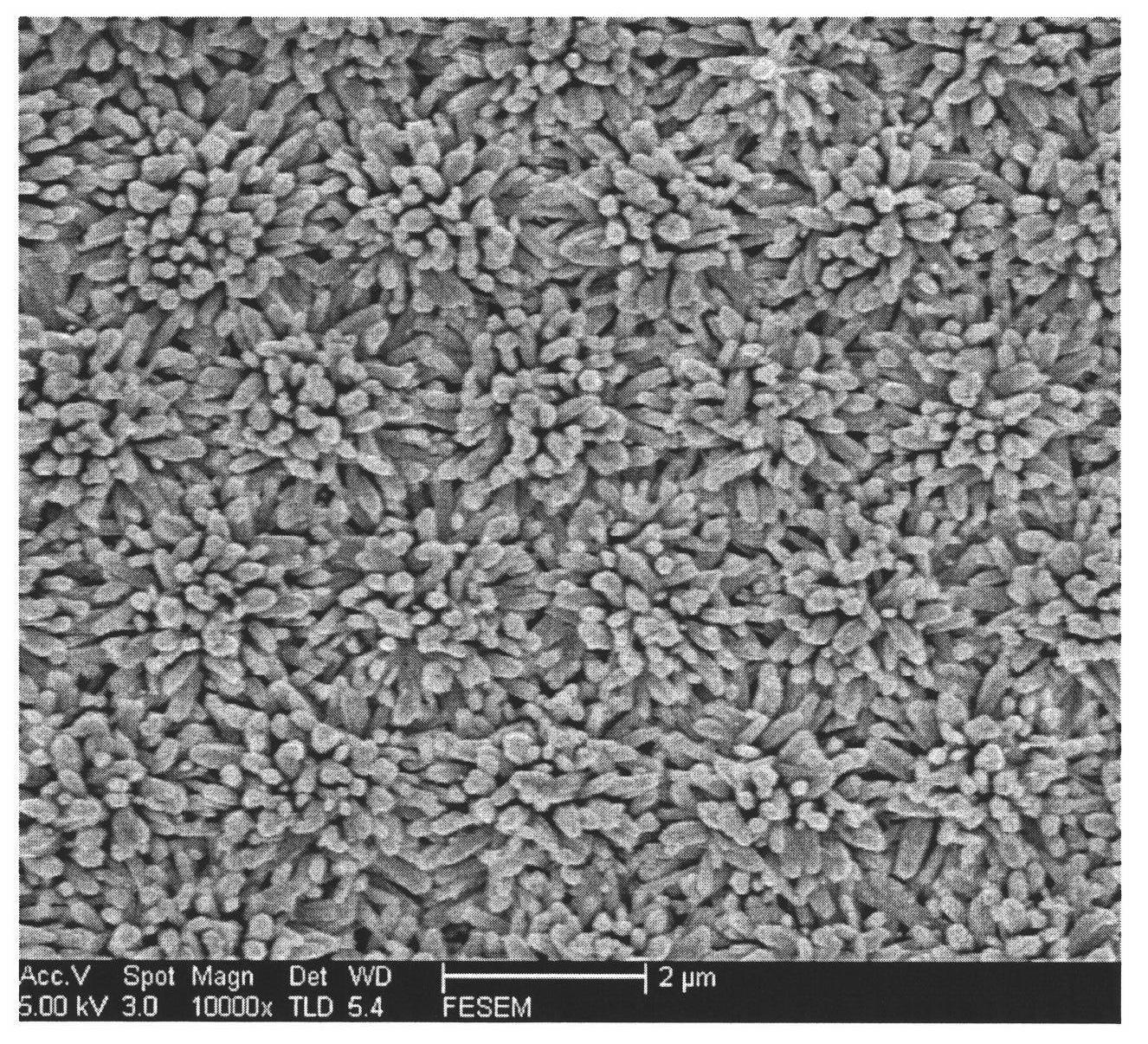

[0024] First, the substrate with a single-layer crystal template composed of polystyrene colloidal spheres (or silica spheres) with a diameter of 2 μm is placed under a pressure of 5 Pa, and a layer with a thickness of 5 nm is deposited by ion sputtering. A gold film to obtain a gold film ball array; wherein, the substrate is glass. Then place the substrate with the gold film ball array on it in the zinc oxide electrolyte at a temperature of 60°C, use it as the working electrode, and deposit it at a deposition current density of -0.3mA / cm 2 The three-electrode method was used for electrodeposition for 4 hours; wherein, the counter electrode in the three-electrode method was a graphite electrode, the reference electrode was a saturated calomel electrode, and the zinc oxide electrolyte was a zinc nitrate solution with a concentration of 0.03M. made approximately figure 1 The dielectric spheres shown are polystyrene colloidal sphe...

Embodiment 2

[0028] The concrete steps of preparation are:

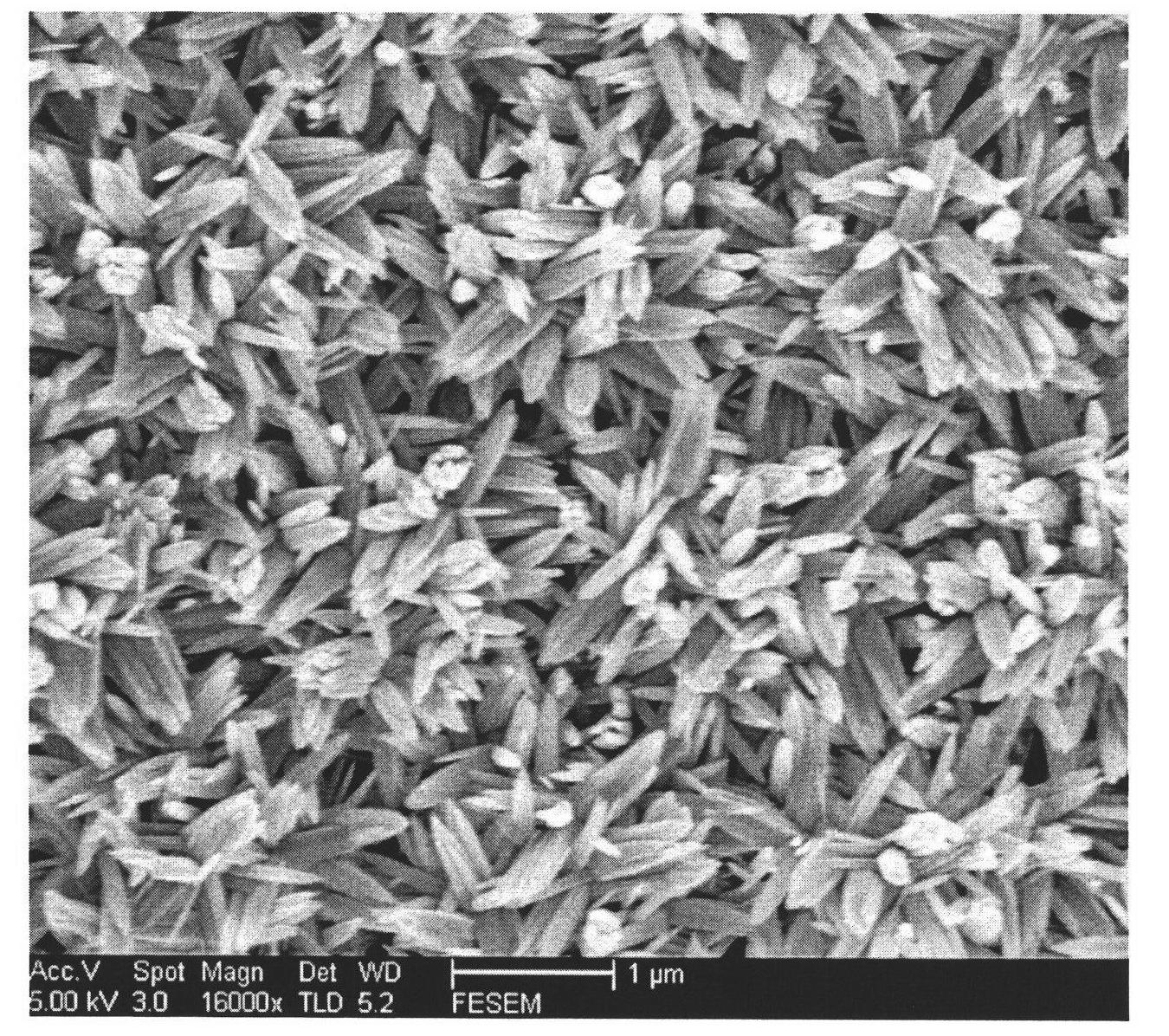

[0029] First, the substrate with a single-layer crystal template composed of polystyrene colloidal spheres (or silicon dioxide spheres) with a diameter of 2 μm is placed under a pressure of 6.5 Pa, and a layer of 15 nm-thickness is deposited by ion sputtering. layer gold film to obtain a gold film ball array; wherein, the substrate is glass. Then place the substrate with the gold film ball array on it in the zinc oxide electrolyte at a temperature of 65°C, use it as the working electrode, and deposit it at a deposition current density of -0.6mA / cm 2 The three-electrode method was used for electrodeposition for 2.5 hours; wherein, the counter electrode in the three-electrode method was a graphite electrode, the reference electrode was a saturated calomel electrode, and the zinc oxide electrolyte was a zinc nitrate solution with a concentration of 0.04M. made approximately figure 1 The dielectric spheres shown are polystyrene col...

Embodiment 3

[0033] The concrete steps of preparation are:

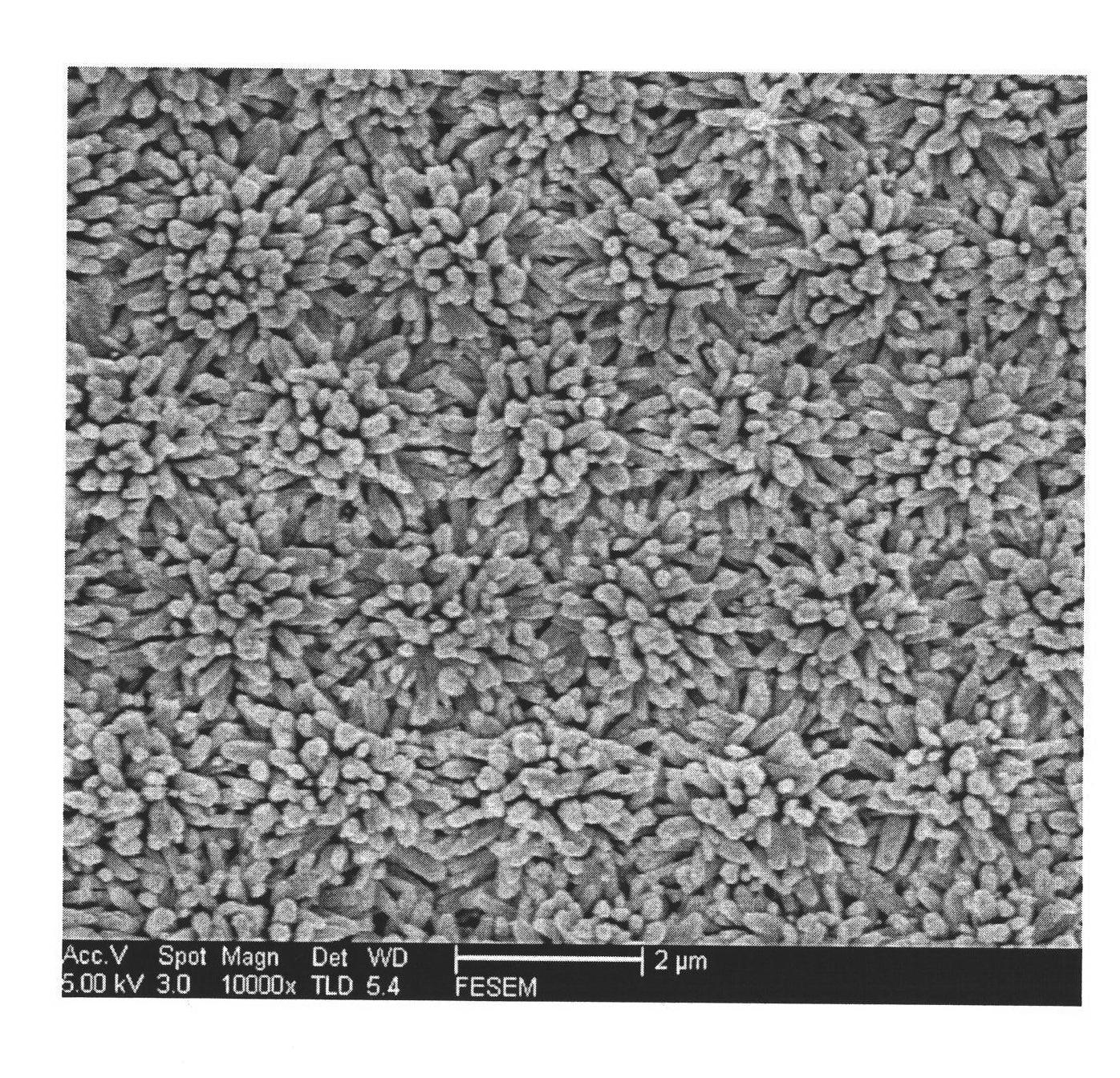

[0034] First place the substrate with a single-layer crystal template composed of polystyrene colloidal spheres (or silica spheres) with a diameter of 2 μm under a pressure of 8 Pa, and deposit a layer with a thickness of 25 nm by ion sputtering. A gold film to obtain a gold film ball array; wherein, the substrate is glass. Then place the substrate with the gold film ball array on it in the zinc oxide electrolyte at a temperature of 70°C, use it as the working electrode, and deposit it at a deposition current density of -1mA / cm 2 The three-electrode method was used for electrodeposition for 1 h; wherein, the counter electrode in the three-electrode method was a graphite electrode, the reference electrode was a saturated calomel electrode, and the zinc oxide electrolyte was a zinc nitrate solution with a concentration of 0.05M. made as figure 1 The dielectric spheres shown are polystyrene colloidal spheres, and the outer surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com