Halogen-free resin composition and prepreg and laminated board made of same

A technology of resin composition and prepreg, which is applied in the direction of synthetic resin layered products, lamination, lamination devices, etc., can solve the problems that cannot meet the application requirements, reduce heat resistance, moisture resistance thermal expansion coefficient and mechanical properties, etc., and achieve Excellent moisture and heat resistance and heat resistance, low thermal expansion coefficient, low heat resistance, and excellent moisture and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

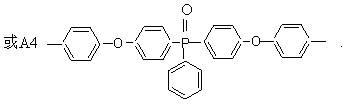

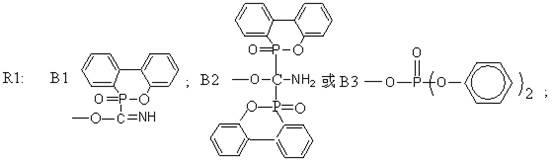

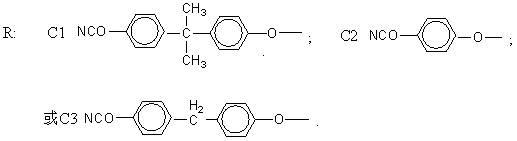

[0049] Take bismaleimide resin powder solid 25g, add appropriate amount of DMF to dissolve. After the bismaleimide resin powder is dissolved until clear and transparent, add 20g of bisphenol A cyanate resin (CY-10, Wuqiao Chemical) and 20g of phosphorous cyanate resin (structure such as structural formula 1, R= A1), 35g dicyclopentadiene type epoxy resin (XD-1000, Nippon Kayaku), 0.05g stannous octoate, 50g spherical silica (average particle size 0.7um), 50g boehmite and appropriate amount of butanone The solvent was stirred and mixed to obtain a glue solution with a solid content of 60%.

[0050] The glue is dipped and coated on E glass fiber cloth (2116, the unit weight is 104g / m 2 ) and baked in an oven at 170°C for 5 minutes to obtain a prepreg with a resin content of 50%.

[0051]The prepared prepreg with a resin content of 50% was put on top and bottom of a piece of copper foil, and pressed in a vacuum hot press to obtain a copper-clad laminate; the specific pressing p...

Embodiment 2

[0054] Take 20g of bismaleimide resin powder solid, add an appropriate amount of DMF to dissolve; after the bismaleimide resin powder is dissolved until clear and transparent, add 20g of bisphenol A cyanate resin (CY-10, Wuqiao Chemical ), 15g of phosphorus-containing cyanate resin (structure such as structural formula 3, R=C2), 45g of biphenyl type epoxy resin (NC-3000, Nippon Kayaku), 0.05g of stannous octoate, 0.2g of 2-ethyl- 4-Methylimidazole, 80g spherical silica (average particle size 0.7um), 20g aluminum hydroxide and an appropriate amount of butanone solvent were stirred and mixed to obtain a glue with a solid content of 60%.

[0055] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

[0056] The properties of the obtained copper-clad laminates are shown in Table 1.

Embodiment 3

[0058] Take 15g of the solid bismaleimide resin powder, add an appropriate amount of DMF to dissolve it; after the bismaleimide resin powder is dissolved until clear and transparent, add 15g of bisphenol A cyanate resin (CY-10, Wuqiao Chemical ), 15g phosphorous cyanate resin (structure such as structural formula 1, R=A1), 55g naphthalene ring epoxy resin (NC-7300, Nippon Kayaku), 0.05g stannous octoate, 0.5g 2-methylimidazole , 60g of spherical silica (average particle size 0.7um), 40g of boehmite and an appropriate amount of butanone solvent were stirred and mixed to obtain a glue with a solid content of 60%.

[0059] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

[0060] The properties of the obtained copper-clad laminates are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com