Starch stypticum and preparation method thereof

A technology of hemostatic agent and starch, which is applied in blood diseases, surgical drugs, extracellular fluid diseases, etc. It can solve the problems of low amylopectin content, reduction of starch micropores, and insufficient water absorption, so as to inhibit bleeding, Effect of improving migration ability and reducing bleeding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

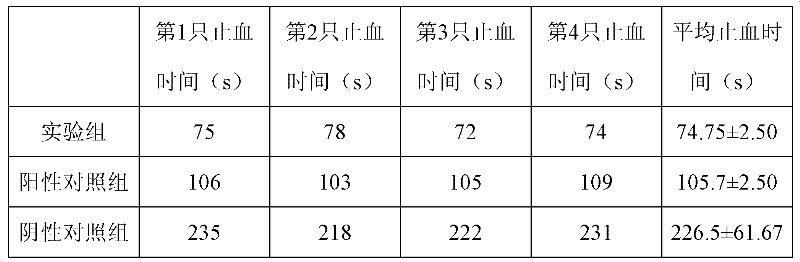

Examples

Embodiment 1

[0015] Mill 100Kg of waxy cornstarch with a stirring ball mill to 5000 mesh, put it into the reaction tank, add 300Kg of water, and then add 0.02Kg of borax crosslinking agent, the reaction temperature is 40°C, and react for 50min; after the crosslinking reaction is completed, add 8Kg hydrochloric acid for acid hydrolysis, the acid hydrolysis reaction time is 60min, and the acid hydrolysis reaction temperature is 40°C; after the acid hydrolysis is completed, adjust the pH value to 4.0 with acetic acid, add 1Kg compound enzyme (alpha-amylase and glucoamylase each 50%) to carry out Enzymolysis, the enzymolysis reaction time is 8 hours, and the enzymolysis reaction temperature is 45°C; after the enzymolysis reaction is completed, centrifuge and filter, wash with distilled water for 3 times; Sieve; sterilize with Co60 irradiation to obtain starch hemostatic agent.

Embodiment 2

[0017] Mill 100Kg of waxy cornstarch with a stirring ball mill to 6000 mesh, put it into the reaction tank, add 200Kg of water, and then add 0.02Kg of borax cross-linking agent, the reaction temperature is 50°C, and react for 40 minutes; after the cross-linking reaction is completed, add 9Kg hydrochloric acid for acid hydrolysis, the acid hydrolysis reaction time is 30min, and the acid hydrolysis reaction temperature is 50°C; after the acid hydrolysis is completed, the pH value is adjusted to 4.5 with acetic acid, and 0.8Kg compound enzyme (50% of α-amylase and glucoamylase each) is added. Carry out enzymolysis, the enzymolysis reaction time is 10h, the enzymolysis reaction temperature is 50 ℃; After the enzymolysis reaction is completed, centrifuge and filter, wash 3 times with distilled water; Mesh sieve; sterilized by Co60 irradiation to obtain starch hemostatic agent.

Embodiment 3

[0019] Mill 50Kg of waxy corn starch to 8000 mesh with a stirring ball mill, add to the reaction tank, add 150Kg of water, and then add 0.03Kg of borax cross-linking agent, the reaction temperature is 55°C, and react for 45 minutes; after the cross-linking reaction is completed, add 6Kg hydrochloric acid for acid hydrolysis, the acid hydrolysis reaction time is 80min, and the acid hydrolysis reaction temperature is 50°C; after the acid hydrolysis is completed, the pH value is adjusted to 5.5 with acetic acid, and 0.6Kg compound enzyme (50% of α-amylase and glucoamylase each) is added. Carry out enzymolysis, the enzymolysis reaction time is 7h, the enzymolysis reaction temperature is 50 ℃; after the enzymolysis reaction is completed, centrifuge and filter, wash with distilled water 3 times; Mesh sieve; sterilized by Co60 irradiation to obtain starch hemostatic agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com