Manufacturing method of tunable triangular metal nano particle array structure

A metal nanoparticle and array structure technology, applied in nanotechnology, microstructure technology, microstructure devices and other directions, can solve the problems of high processing cost and time-consuming, and achieve low cost, controllable optical properties, and obvious extinction spectrum peak. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

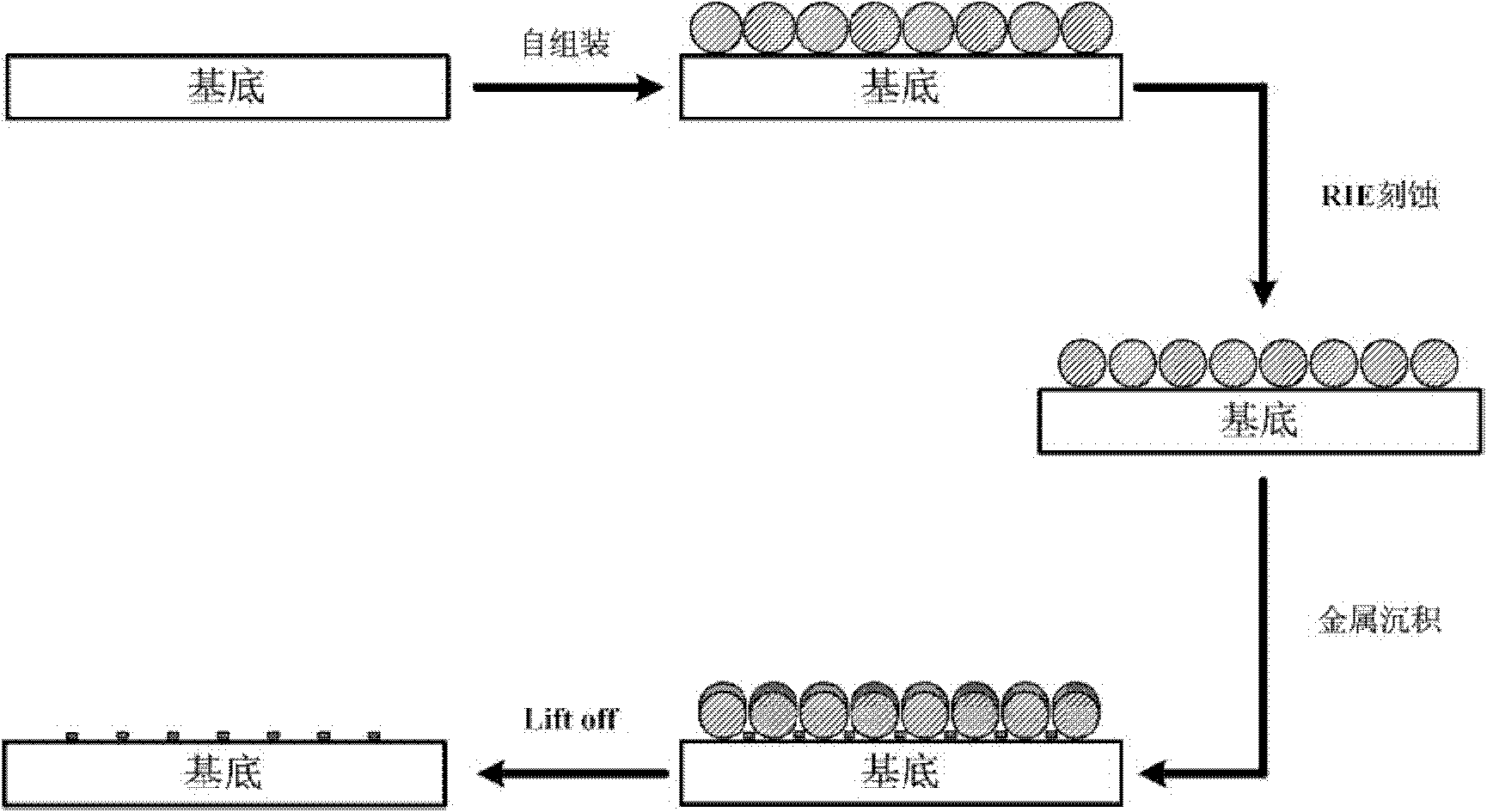

Method used

Image

Examples

Embodiment 1

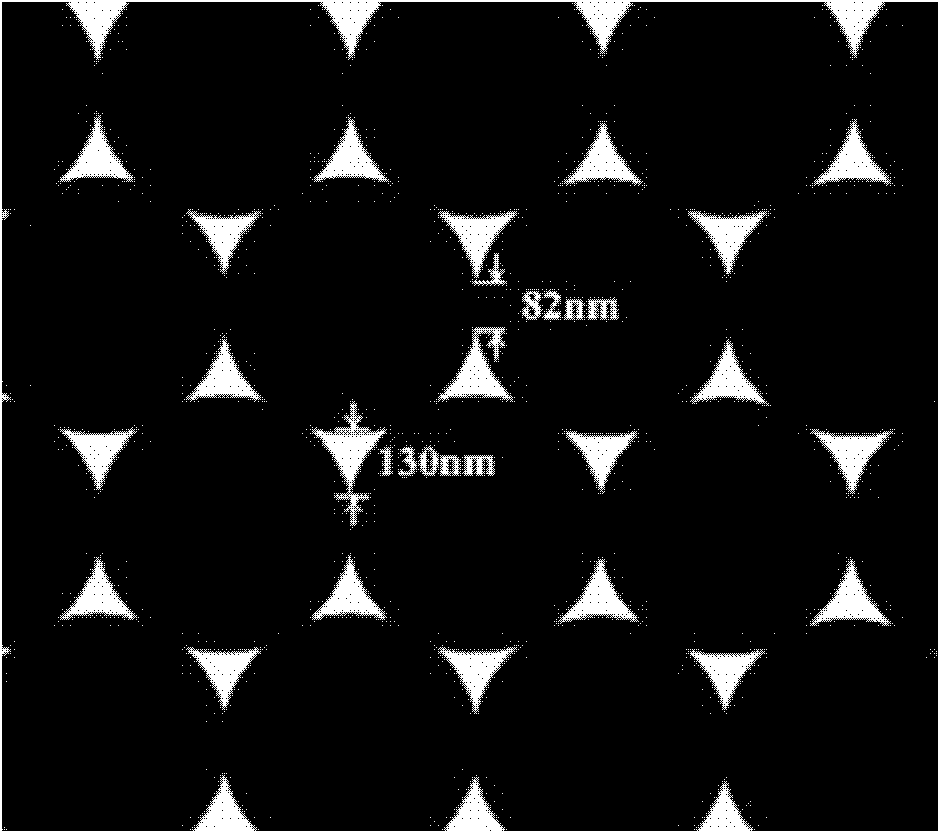

[0031] Example 1, using the present invention to realize the fabrication of a triangular silver nanoarray structure with a particle diameter of 130nm, a gap between adjacent particle tips of 82nm, and a thickness of 50nm.

[0032] (1) Select K9 glass with a size of 10mm×20mm×10mm as the chip substrate, and clean and hydrophilize the substrate;

[0033] (2) 6 μL of an aqueous solution of monodisperse polystyrene nanospheres with a diameter of 430 nm and a concentration of 10% was dropped onto a glass substrate for self-assembly, and dried at room temperature to obtain a polystyrene nanosphere array arranged in a single layer;

[0034] (3) Etching the self-assembled polystyrene nanospheres with a reactive ion etching machine using oxygen, the power is 5W, the oxygen flow rate is 20SCCM, and the etching time is 2min respectively;

[0035] (4) Put the etched polystyrene nanospheres into the working chamber of the vacuum coating system, -4 Deposit a layer of silver film on its sur...

Embodiment 2

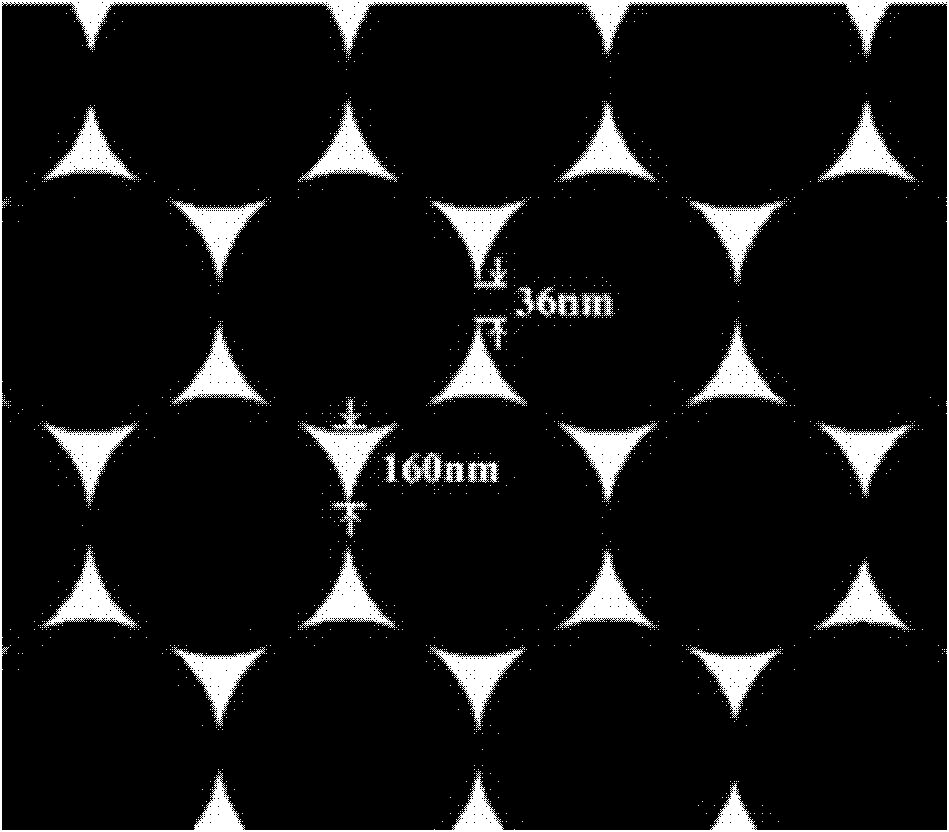

[0038] Example 2, using the present invention to realize the fabrication of a triangular silver nanoarray structure with a particle diameter of 160nm, a gap between adjacent particle tips of 36nm, and a thickness of 50nm.

[0039] (1) Select quartz with a size of 10mm×10mm×10mm as the chip substrate, and clean and hydrophilize the substrate;

[0040] (2) 6 μL of an aqueous solution of monodisperse polystyrene nanospheres with a diameter of 430 nm and a concentration of 10% was dropped onto a glass substrate for self-assembly, and dried at room temperature to obtain a polystyrene nanosphere array arranged in a single layer;

[0041] (3) Etching the self-assembled polystyrene nanospheres with a reactive ion etching machine using oxygen, the power is 5W, the oxygen flow rate is 20SCCM, and the etching time is 4min;

[0042] (4) Put the etched polystyrene nanospheres into the working chamber of the vacuum coating system, -4 Deposit a layer of silver film on its surface under the ...

Embodiment 3

[0045] Example 3, using the present invention to realize the fabrication of a triangular silver nanoarray structure with a particle diameter of 140nm, a gap between adjacent particle tips of 40nm, and a thickness of 40nm.

[0046] (1) Select quartz with a size of 10mm×10mm×10mm as the chip substrate, and clean and hydrophilize the substrate;

[0047] (2) 6 μL of an aqueous solution of monodisperse polystyrene nanospheres with a diameter of 430 nm and a concentration of 10% was dropped onto a glass substrate for self-assembly, and dried at room temperature to obtain a polystyrene nanosphere array arranged in a single layer;

[0048] (3) Etch the self-assembled polystyrene nanospheres with a reactive ion etching machine using oxygen, the power is 5W, the oxygen flow rate is 20SCCM, and the etching time is 2min30s;

[0049] (4) Put the etched polystyrene nanospheres into the working chamber of the vacuum coating system, -4 Deposit a layer of silver film on its surface under the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com