Micro gas chromatographic column with high depth-to-width ratio and wet corrosion manufacturing method thereof

A micro gas chromatography and high aspect ratio technology, which is applied in the field of high aspect ratio micro gas chromatography column and its wet etching, can solve the problems of inability to obtain deep groove structure, high price, and unsatisfactory miniaturization, and achieve the processing method Ease of operation and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention will be further described below by taking specific materials and specific processes as examples, but this does not constitute a limitation to the present invention.

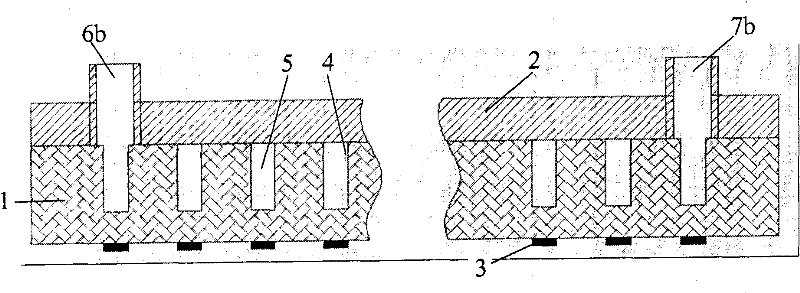

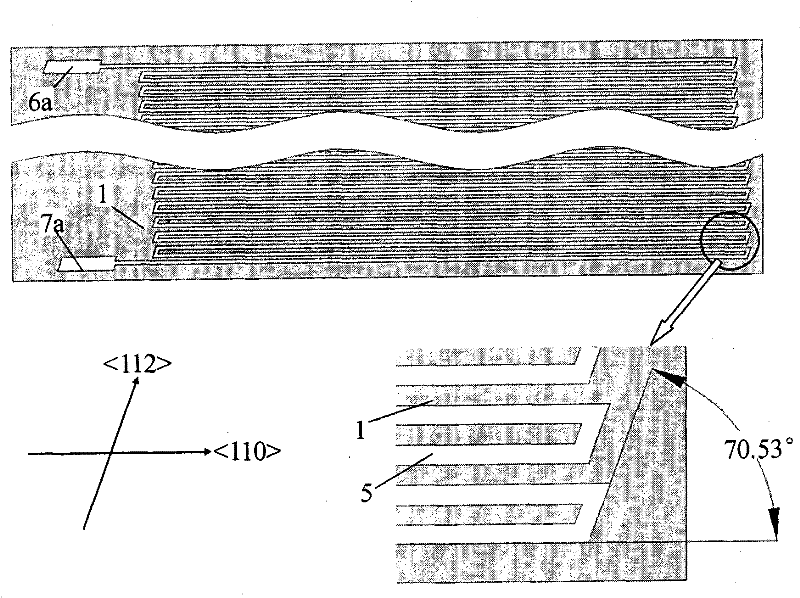

[0031] ①Making of mask: The groove of the chromatographic column is designed as a broken line, the length of the long side is 20mm, the angle between the long side and the short side is 70.53°, the interval between adjacent long sides is 80μm, the width of the groove is also 80μm, and the air inlet 1. The openings 6a and 7a of the vent holes on the silicon wafer have a width of 300 μm and a length of 2mm, so 150 long sides can be arranged in an area of 25mm×25mm, and the total length of the chromatographic channel can reach 3m.

[0032] ②Mask layer thin film preparation: Using PECVD process, put the cleaned P-type, (110) oriented monocrystalline silicon wafer as the substrate into the reaction gas chamber with a thickness of 500 μm ± 10 μm, and put silane and ammonia gas into it. 15...

Embodiment 2

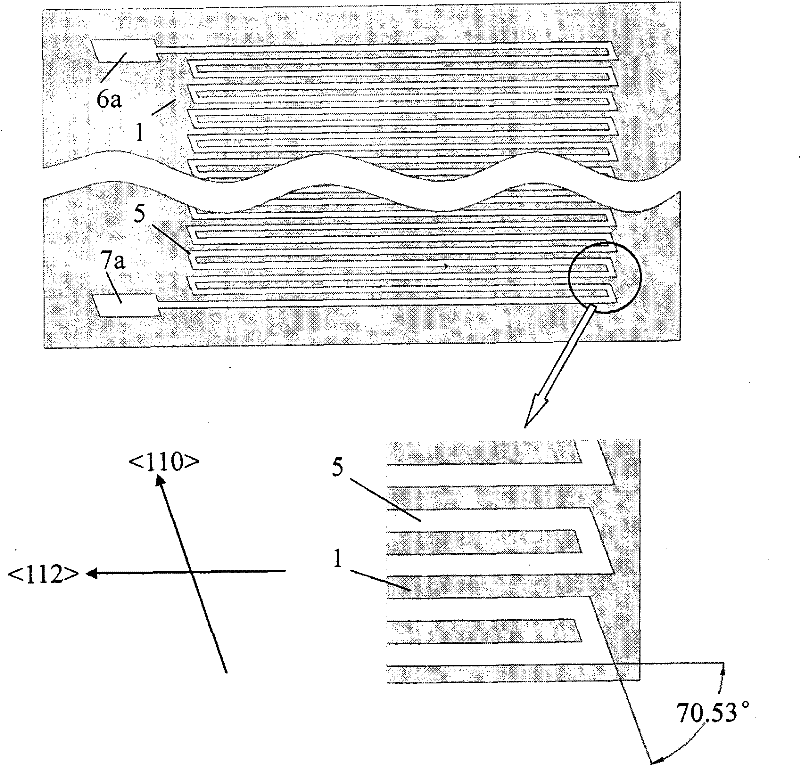

[0039] The serpentine groove of the chromatographic column in this example has a total length of 0.5m. The chromatographic column of this length greatly reduces the separation time while retaining sufficient resolution, so it has important application value in fast and portable chromatographic instruments. The manufacturing process of this example is substantially the same as that of the previous example.

[0040] ①Mask making: The column groove is also designed as a 70.53° broken line, with a long side of 10mm, a total of 50 long sides, a groove width of 120μm, and an interval of 120μm between adjacent long sides, within an area of 12mm×12mm The total length of the chromatographic groove can be realized to be 0.5m.

[0041] ② Preparation of the mask layer film: the same process as in Example 1.

[0042] ③Lithography: In this example, the snake-shaped long side of the mask plate is strictly aligned with the crystal direction of the (110) silicon wafer. Also, since the angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com