Preparation method of porous current collector/tin-base alloy/carbon nano-tube integrated electrode

A technology of porous current collectors and carbon nanotubes, used in battery electrodes, circuits, electrical components, etc., can solve the problems of easy agglomeration, pulverization, shedding, and electrode capacity decay of active materials, and achieve excellent electrochemical performance. Contact area, the effect of simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

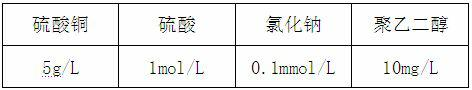

[0015] (1) For the preparation of porous copper current collectors, configure the electrolyte according to the following formula:

[0016]

[0017] At room temperature, both the anode and the working electrode are copper sheets, and the current density is 0.1A / cm 2 , electroplating for 10 min to obtain a porous copper current collector.

[0018] (2) Preparation of porous current collector / tin-based alloy / carbon nanotube integrated electrode

[0019] 1) Prepare tin-cobalt alloy electroplating solution, the process formula is as follows:

[0020]

[0021] Adjust the pH to 5 with ammonia and hydrochloric acid.

[0022] 2) Add carbon nanotubes to the above plating solution, the concentration of carbon nanotubes is 0.6g / L.

[0023] 3) Titanium mesh is used as the anode, the porous copper current collector is used as the cathode, the working temperature is 45°C, and the current density is 0.5A / dm 2 , deposition time 10min. Finally, a porous current collector / tin-based all...

Embodiment 2

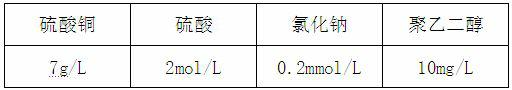

[0025] (1) For the preparation of porous copper current collectors, configure the electrolyte according to the following formula:

[0026]

[0027] At room temperature, both the anode and the working electrode are copper sheets, and the current density is 0.3A / cm 2 , electroplating for 15 minutes to obtain a porous copper current collector.

[0028] (2) Preparation of porous current collector / tin-based alloy / carbon nanotube integrated electrode

[0029] 1) Prepare tin-cobalt alloy electroplating solution, the process formula is as follows:

[0030]

[0031] Adjust the pH to 12 with ammonia and hydrochloric acid.

[0032] 2) Add carbon nanotubes to the above plating solution, the concentration of carbon nanotubes is 1g / L.

[0033] 3) Titanium mesh is used as the anode, the porous copper current collector is used as the cathode, the working temperature is 45°C, and the current density is 0.6A / dm 2 , deposition time 10min. Finally, a porous current collector / tin-based ...

Embodiment 3

[0035] (1) For the preparation of porous copper current collectors, configure the electrolyte according to the following formula:

[0036]

[0037] At room temperature, the pulse electrodeposition preparation technology is adopted, the anode and the working electrode are copper sheets, and the current density is 0.5A / cm 2 , electroplating for 10 min to obtain a porous copper current collector.

[0038] (2) Preparation of porous current collector / tin-based alloy / carbon nanotube integrated electrode

[0039] 1) Prepare tin-cobalt alloy electroplating solution, the process formula is as follows:

[0040]

[0041] Adjust the pH to 8 with ammonia and hydrochloric acid.

[0042] 2) Add carbon nanotubes to the above plating solution, the concentration of carbon nanotubes is 2g / L; in addition, add cetyltrimethylammonium bromide, the concentration is 0.1g / L.

[0043] 3) Titanium mesh is used as the anode, the porous copper current collector is used as the cathode, the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com