Coal-based phenol high-purity refined catalysis adsorbent and preparation method thereof

A coal-based phenol and adsorbent technology, applied in the field of catalysts, can solve the problems of long processing time and low catalyst activity, and achieve the effects of low cost, improved activity and stability, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

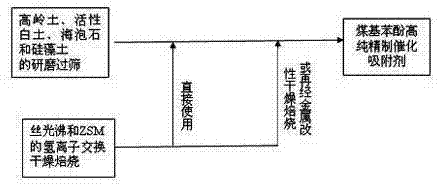

[0042] The preparation method of the coal-based phenol high-purity refined catalytic adsorbent under the first technical scheme comprises the following steps:

[0043] a 1 ), take the solid active components kaolin, attapulgite, sepiolite and diatomaceous earth according to the mass percentage of the first technical scheme, and grind and sieve respectively;

[0044] b 1 ), and mix the ground and sieved components.

[0045] In the second technical scheme of a coal-based phenol high-purity refined catalytic adsorbent, the coal-based phenol high-purity refined catalytic adsorbent includes the following components in mass percentage:

[0046] Kaolin 0-99%

[0047] Activated clay 15-99%

[0048] Sepiolite 0-20%

[0049] Diatomaceous earth 0-45%

[0050] Mordenite 0-80%

[0051]ZSM molecular sieve 0-99%.

[0052] The preparation method of the coal-based phenol high-purity refined catalytic adsorbent under the second technical scheme comprises the following steps:

[0053] a...

Embodiment 1

[0074] The components of the coal-based phenol high-purity catalytic adsorbent in this embodiment are as follows: 40% diatomite, 38% attapulgite, and 22% sepiolite in terms of mass percentage. These raw materials are ground, sieved and mixed to prepare the catalyst. Coal tar phenol fraction is used as raw material (impurity S content ≥ 1000ppm), the temperature is 120°C, the amount of coal-based phenol high-purity refined catalytic adsorbent is 5% of the mass of the phenol fraction, the reaction time is 180min, and the obtained liquid phase product is in a vacuum of 730mmHg Under the condition of rectification and purification, the S content of refined phenol in the distillate was measured by a sulfur analyzer to drop to 132ppm, and the desulfurization rate was ≥ 86.8%.

Embodiment 2

[0076] The ZSM molecular sieve, one of the raw materials of the coal-based phenol high-purity refined catalytic adsorbent in this embodiment, has completed ion exchange and metal ion replacement in advance through nitric acid and copper nitrate aqueous solution. The conditions are: ion exchange, HNO 3 The concentration is 5mol / l, the reaction temperature is 92°C, the reaction time is 5h, the drying condition is 95°C, 6h, the roasting condition is 390°C, 4h; metal ion exchange, HNO 3 The concentration is 5mol / l, the reaction temperature is 88°C, the reaction time is 4h, the drying conditions are 105°C, 5h, the roasting conditions are 410°C, 5h, and the total mass content of copper is 2.1%. The component content of the coal-based phenol high-purity catalytic adsorbent is as follows: kaolin 5%, activated clay 40%, ZSM molecular sieve 43%, sepiolite 10%, these raw materials are ground and sieved and mixed to prepare the catalyst. Coal tar phenol fraction is used as raw material (i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com