Method and device for synthesizing compound by solid phase reaction

A technology of solid phase reaction and solid reactants, which is applied in the field of solid phase reaction synthesis of compounds, can solve problems such as narrow application range, high cost, and wear of grinding balls, and achieve the effects of wide application range, fast reaction speed, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

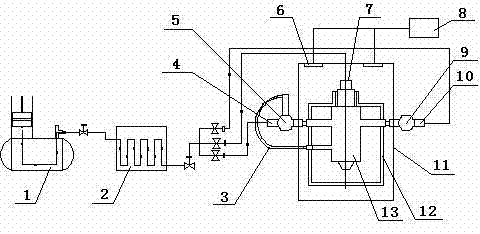

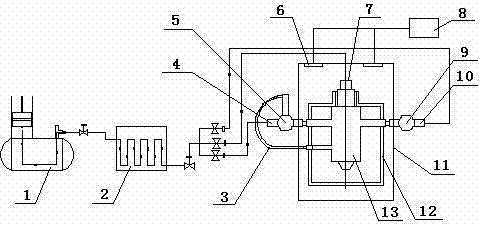

Method used

Image

Examples

Embodiment 1

[0032] Solid Phase Synthesis of Isopropylidene p-Nitrophenylmalonate

[0033] Use isopropylidene malonate and p-nitrobenzaldehyde as raw materials: uniformly mix according to the ratio of the substances of 1:1, the mixed material enters the supersonic nozzle through negative pressure ejection, and expands rapidly after accelerating in the nozzle A supersonic mixing system is generated, followed by violent friction and collision in the reactor, and finally hits a fixed target at high speed, and then merges with the airflow and enters the circulation system at a speed of 30 m / s. The particles in the reaction system settle, enrich and enter the nozzle again, After circulating in the generator for a period of time, take samples for analysis, then fully wash with 65°C distilled water three times, drain, recrystallize with 95% ethanol, and dry in a vacuum dryer (40°C) for 8 hours to obtain the white target product Isopropylidene p-nitrophenylmalonate.

[0034] When preparing isopro...

Embodiment 2

[0036] Solid Phase Synthesis of Isopropylidene p-Hydroxyphenylmalonate

[0037]Using isopropylidene malonate and p-hydroxybenzaldehyde as raw materials: uniformly mixed according to the ratio of the substances in the amount of 1:1, the mixed material enters the supersonic nozzle through negative pressure ejection, and expands rapidly after accelerating in the nozzle to produce The supersonic mixing system, followed by violent friction and collision in the reactor, finally hits the fixed target at high speed, and then merges with the airflow and enters the circulation system at a speed of 30 m / s. The particles in the reaction system settle, enrich and enter the nozzle again. After circulating in the container for a period of time, take a sample for analysis, then fully wash with 65°C distilled water three times, drain, recrystallize with 95% ethanol, and dry in a vacuum dryer (40°C) for 8 hours to obtain the white target product .

[0038] When preparing isopropylidene p-nitro...

Embodiment 3

[0040] Preparation of ultrafine calcium carbonate.

[0041] Mix 70-mesh anhydrous calcium chloride (0.1380 kg) and sodium carbonate (0.1363 kg) at a molar ratio of 1:1 to make them collide with a fixed target in the reactor at 3 times the speed of sound, and react in the reaction generator. After circulating the reaction for a period of time, the mixture was fully washed 3 times with distilled water, then 2 times with absolute ethanol, and dried to obtain superfine calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com