Chromium-containing light hydrocarbon combustion catalyst and preparation method thereof

A technology of burning catalysts and catalysts, which is applied in the direction of catalyst activation/preparation, combustion methods, combustion equipment, etc., which can solve the problems of low catalytic activity, inability to improve reaction activity, small specific surface area, etc., and achieve simple preparation process and good light hydrocarbon catalysis The effect of combustion activity and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

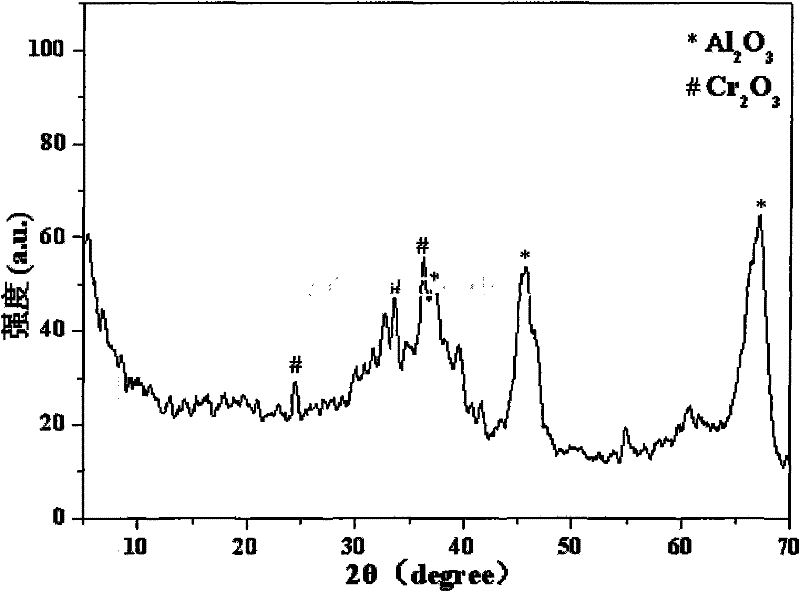

Embodiment 1

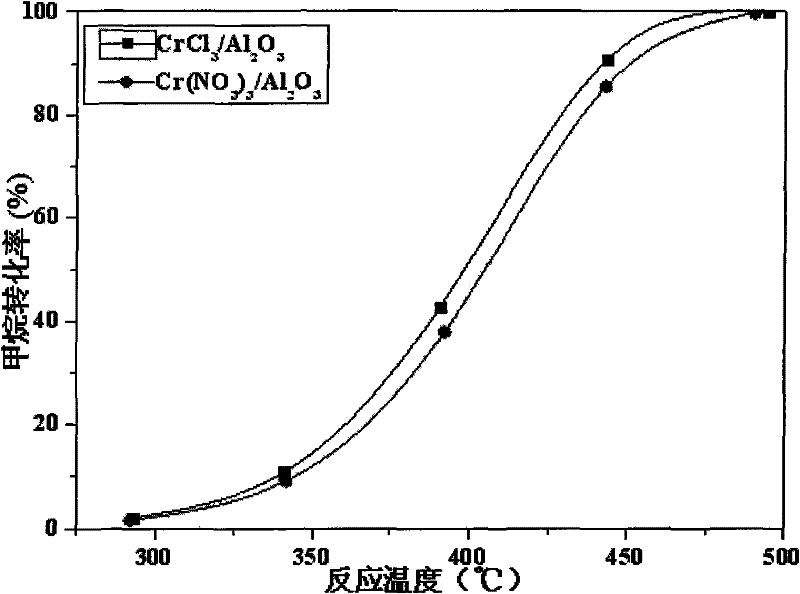

[0023] Weigh 3.6189g of Cr (NO 3 ) 3 9H 2 O was dissolved in 3.2ml deionized water at 25°C, and the Cr(NO 3 ) 3 The aqueous solution was added dropwise with 4g nanometer γ-Al 2 o 3 In the process, an equal-volume impregnation was formed, standing at 25°C for 3h, overnight at 70°C, ordinary drying at 110°C for 3h, grinding, and roasting at 500°C for 4h in a muffle furnace to obtain Cr(NO 3 ) 3 / γ-Al 2 o 3 catalyst.

Embodiment 2

[0025] Weigh 2.8148g of CrCl 3 ·6H 2 O was dissolved in 3.5 ml deionized water at 25 °C, and the CrCl 3 The aqueous solution was added dropwise with 4g nanometer γ-Al 2 o 3 In the process, an equal volume impregnation is formed, standing at 25°C for 3h, overnight at 70°C, ordinary drying at 110°C for 3h, grinding, and roasting at 500°C for 4h in a muffle furnace to obtain CrCl 3 / γ-Al 2 o 3 catalyst.

Embodiment 3

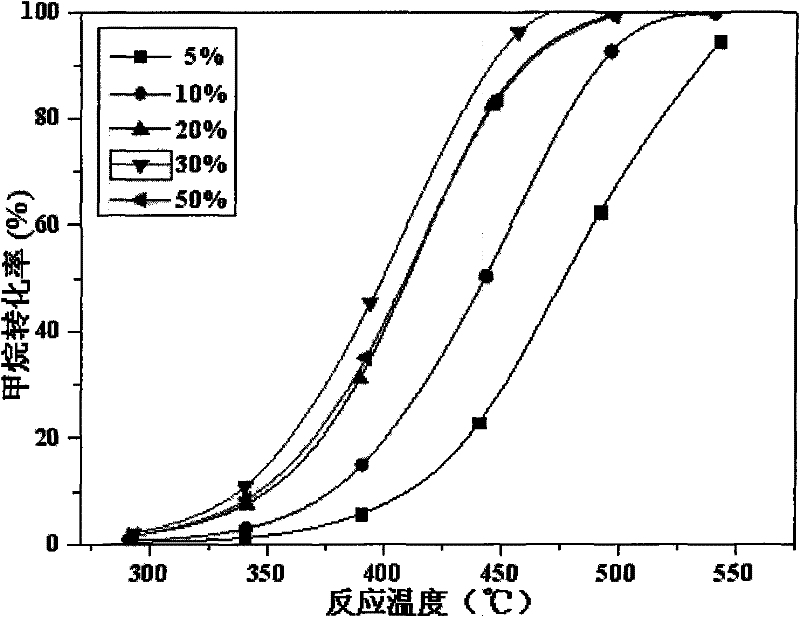

[0027] Weigh 0.5259g-5.259g of CrCl 3 ·6H 2 O was dissolved in 2.5-5ml deionized water, and the chromium chloride aqueous solution was added dropwise to 3g nanometer γ-Al 2 o 3 , put it in a vacuum drying oven, dry overnight at 70°C in vacuum, dry at 110°C for 3 hours, grind it, and roast it in a muffle furnace at 500°C for 4 hours to obtain 5%-50% CrCl 3 / γ-Al 2 o 3 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com