Copper-clad laminate-based method for micro-removing copper film from selected area by assistance of laser

A laser-assisted, copper-clad laminate technology, applied in the field of micro-machining, can solve the problems of complex operation, high cost, environmental pollution, etc., and achieve the effects of good controllability, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

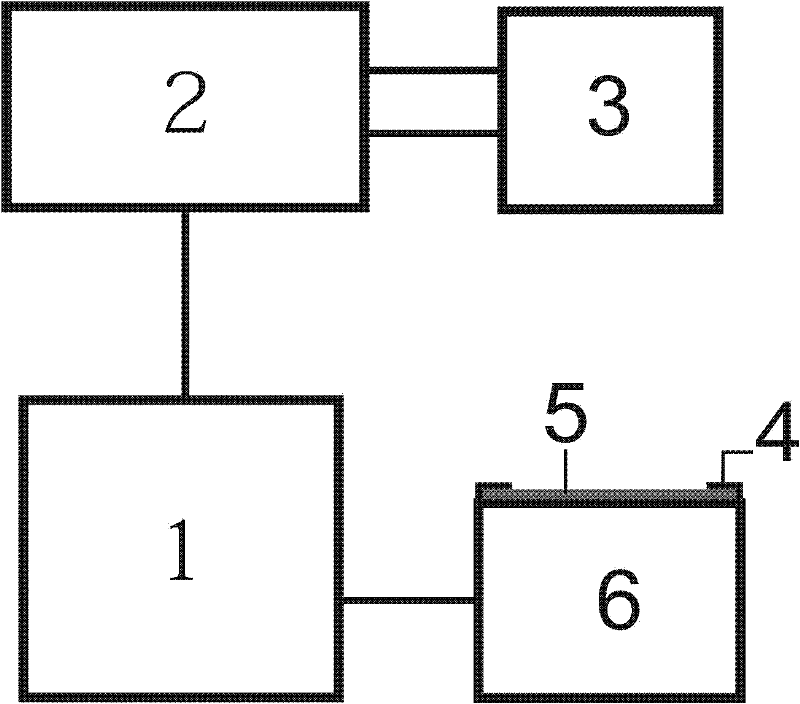

Method used

Image

Examples

example 1

[0036] The example of the present invention selects a fiber laser with small volume, good beam quality, and convenient processing, and the laser motion control system adopts a scanning vibrating mirror; the copper clad plate is a flexible copper clad plate with a base film of 70 μm polyester film plated with 18 μm copper foil; selects 5% hydrogen peroxide A mixed solution of 15% hydrochloric acid is used as an etchant; a quick-drying thermoplastic acrylic aerosol paint is selected as a coating; PHOTOSHOP software is selected as a drawing software; a ring with an outer diameter of 10mm, an inner diameter of 6mm, and a regular five-pointed star with a size of 10mm are selected as the removal agent. Pattern; use ultrasound to remove final paint.

[0037]This example is carried out as follows: spray the quick-drying thermoplastic acrylic aerosol paint evenly on the copper foil, and after the spray paint is dry, place the copper clad laminate on the focal plane of the laser vibratin...

example 2

[0039] The example of the present invention selects the small CO with the maximum power of 30W 2 The laser and the laser motion control system adopt three-dimensional numerical control machine tools; the copper-clad laminate adopts a base film of 70 μm polyester film and a flexible copper-clad laminate plated with 18 μm copper foil; selects 50% ferric chloride solution as the etchant; selects silica gel as the coating; selects PHOTOSHOP software is used as the drawing software; a ring with an outer diameter of 10mm and an inner diameter of 6mm, and a regular five-pointed star with a size of 10mm are selected as the removal pattern; ultrasonic waves are used to remove the final paint.

[0040] This example is carried out as follows: apply silica gel evenly on the copper foil, and after the silica gel dries, place the copper clad laminate on the focal plane of the laser lens on the workbench and fix it with a fixture; draw an outer diameter of 10mm in the PS software , a ring wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com