Carbosulfan microcapsule suspending agent and preparation method thereof

A technology of microcapsule suspension and carbosulfan, applied in botany equipment and methods, insecticides, acaricides, etc., can solve the problems of destroying the stability of microcapsules and the toxic effect of the environment, and achieve reduction Free formaldehyde and urea content, improved safety, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

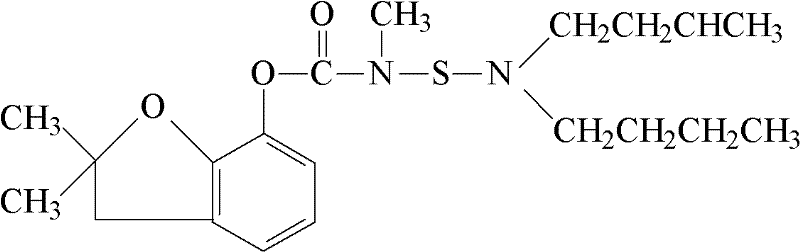

[0052] Embodiment 1: carbosulfan microcapsule suspension

[0053] 1. Preparation method

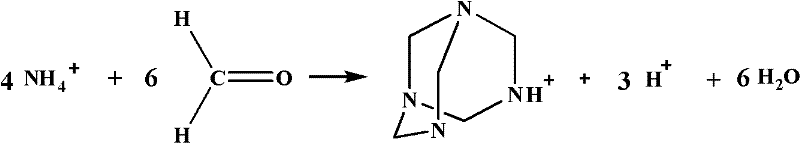

[0054] 1) Preparation of urea-formaldehyde resin prepolymer: Dissolve 60.0 g of urea in 81.0 g of 37% formaldehyde solution (the urea-formaldehyde molar ratio is 1:1), add 0.3 g of triethanolamine to adjust the pH value to 7.5, and heat up to 80° C. , heat preservation reaction for 1h to obtain urea-formaldehyde resin prepolymer;

[0055] 2) Emulsification: Add 2.0g of emulsifier (1.7g of phenylethylphenol polyoxyethylene polyoxypropylene ether, 0.3g of calcium dodecylbenzenesulfonate) to 5.0g of carbosulfan crude oil, mix well, Then add 30.0g deionized water and stir and emulsify for 30min to obtain O / W emulsion;

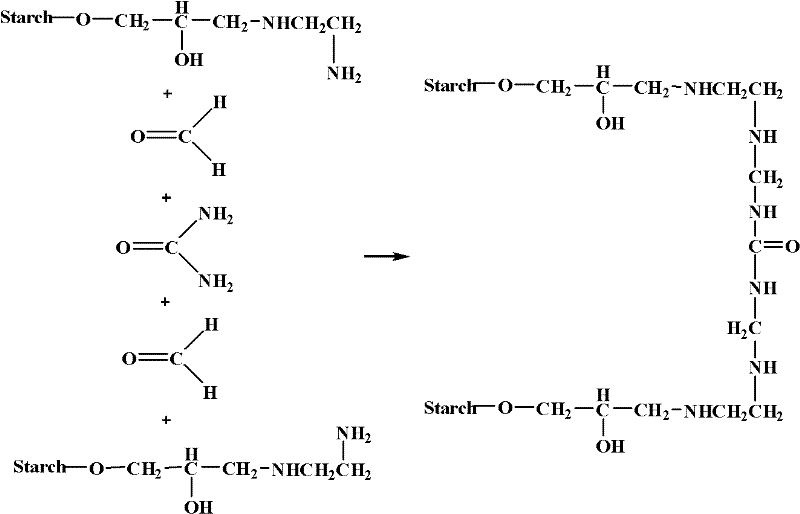

[0056] 3) Polymerization: Add 5.0g of urea-formaldehyde resin prepolymer and 1.0g of amino starch dropwise to the O / W emulsion under stirring conditions, adjust the pH value to 3.0 with 3% acetic acid, heat up to 40°C, and keep warm After reacting for 1h, add 0.1g polypropy...

Embodiment 2

[0060] Embodiment 2: carbosulfan microcapsule suspension

[0061] 1. Preparation method

[0062] 1) Preparation of urea-formaldehyde resin prepolymer: Dissolve 60.0g urea in 97.3g mass concentration of 37% formaldehyde solution (urea-formaldehyde molar ratio is 1:1.2), add 0.4g triethanolamine to adjust pH value to 7.8, and heat up to 70°C , heat preservation reaction for 1h to obtain urea-formaldehyde resin prepolymer;

[0063] 2) Emulsification: Add 2.0g of emulsifier (1.7g of phenylethylphenol polyoxyethylene polyoxypropylene ether, 0.3g of calcium dodecylbenzenesulfonate) into 5.0g of carbosulfan, mix well, and then Add 10.0g deionized water and stir and emulsify for 30min to obtain O / W emulsion;

[0064] 3) Polymerization: Add 5.0g of urea-formaldehyde resin prepolymer and 1.0g of amino starch dropwise to the O / W emulsion under stirring conditions, adjust the pH value to 3.0 with oxalic acid with a mass concentration of 3%, raise the temperature to 40°C, and keep warm ...

Embodiment 3

[0068] Embodiment 3: carbosulfan microcapsule suspension

[0069] 1. Preparation method

[0070] 1) Preparation of urea-formaldehyde resin prepolymer: Dissolve 90.0 g of urea in 206.8 g of 37% formaldehyde solution (the urea-formaldehyde molar ratio is 1:1.7), add 0.5 g of triethanolamine to adjust the pH value to 8.5, and heat up to 60°C , heat preservation reaction for 1.5h to obtain urea-formaldehyde resin prepolymer;

[0071] 2) Emulsification: Add 2.0g of emulsifier (1.7g of phenylethylphenol polyoxyethylene polyoxypropylene ether, 0.3g of calcium dodecylbenzenesulfonate) into 5.0g of carbosulfan, mix well, and then Add 15.3g of deionized water and stir and emulsify for 10min to obtain an O / W emulsion;

[0072] 3) Polymerization: Add 5.0 g of urea-formaldehyde resin prepolymer and 5.0 g of amino starch dropwise to the O / W emulsion under stirring conditions, adjust the pH value to 3.0 with phosphoric acid with a mass concentration of 2%, raise the temperature to 40°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com