Method for producing biological organic fertilizer by using methane liquid as basic culture medium through fermentation

A technology of bio-organic fertilizer and basal medium, which is applied in the field of fermenting bio-organic fertilizer based on biogas slurry as a basal medium, which can solve the problems of limited application and promotion, high price of biological pesticides, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

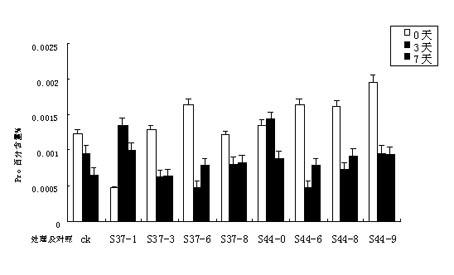

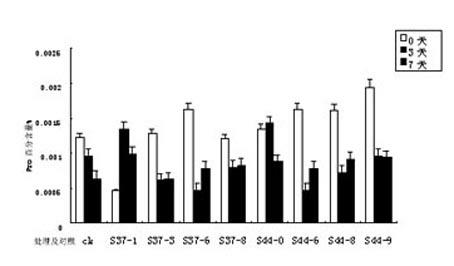

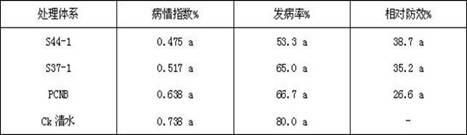

Image

Examples

Embodiment 1

[0053] Embodiment 1: A kind of method that takes biogas slurry as base medium fermentation to produce bio-organic fertilizer is characterized in that mainly comprising the following method steps:

[0054] (1) Preparation of fermentation medium: every 1000mL of biogas slurry is mixed with the following components by weight to obtain a fermentation medium: 10g of corn flour, 10g of soybean meal, 1g of potassium dihydrogen phosphate, 15g of calcium carbonate, sulfuric acid Magnesium 0.5g, Ammonium Sulfate 1g, Glycine 0.5g, Sodium Chloride 1.5g, Potassium Nitrate 2g, sterilize the above fermentation medium for later use, sterilization conditions: 0.15Mpa, 121°C steam sterilization for 30min;

[0055] (2) Streak the Bacillus subtilis preserved at low temperature and glycerol on the slant of the NA nutrient agar medium test tube, and culture it in a 28°C incubator for 24 hours to obtain the spare slant strains. The NA nutrient agar medium includes Prepared from the following compone...

Embodiment 2

[0061] Embodiment 2: Compared with Embodiment 1, this embodiment differs in that:

[0062] The method step (1) is: preparation of fermentation medium: every 1000mL of biogas slurry is mixed with the following components by weight to form a liquid to obtain the fermentation medium: 15g of corn flour, 10g of soybean meal, 2g of potassium dihydrogen phosphate, calcium carbonate 20g, 1g of magnesium sulfate, 1.5g of ammonium sulfate, 0.5g of glycine, 1.5g of sodium chloride, and 4g of potassium nitrate. Sterilize the above fermentation medium for later use. Sterilization conditions: 0.15Mpa, steam sterilization at 121°C for 30min;

[0063] Method step (6) is: add standby fermentation medium in 1000L stirring fermenter, the filling volume of fermentation medium is 600L, 0.10% (w / v) antifoaming agent, by the insertion amount of 60L namely 10 % Connect the third-grade seed liquid, under the conditions of 30°C ventilation rate 10L / min, tank pressure 80kPa, stirring speed 220r / min, and...

Embodiment 3

[0065] Embodiment 3: Compared with Embodiment 1, the present embodiment differs in that:

[0066] The method step (1) is: preparation of fermentation medium: every 1000mL of biogas slurry is mixed with the following components by weight to form a liquid to obtain the fermentation medium: 15g of corn flour, 15g of soybean meal, 2g of potassium dihydrogen phosphate, calcium carbonate 20g, 1g of magnesium sulfate, 1.5g of ammonium sulfate, 0.5g of glycine, 1.5g of sodium chloride, and 4g of potassium nitrate. Sterilize the above fermentation medium for later use. Sterilization conditions: 0.15Mpa, steam sterilization at 121°C for 30min;

[0067] Method step (6) is: add standby fermentation medium in 1000L stirring fermenter, the filling volume of fermentation medium is 600L, 0.10% (w / v) antifoaming agent, by the insertion amount of 60L namely 10 % Insert the third-grade seed liquid, under the conditions of 30°C ventilation rate 10L / min, tank pressure 80kPa, stirring speed 200r / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com