Benzyl-contained cationic polymerizable surface activated monomer and preparation method and ionic copolymer

An ionic copolymer, cationic technology, applied in the preparation of organic compounds, the preparation of aminohydroxy compounds, chemical instruments and methods, etc., can solve the problem of long carbon chains prone to curling and shrinking, unfavorable surface active monomers, and reduced polymerization activity. problems, to achieve the effect of convenient source of raw materials, easy purification and moderate dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This example is used to illustrate the benzyl group-containing cationic polymerizable surfactant monomer and its preparation method and ionic copolymer of the present invention.

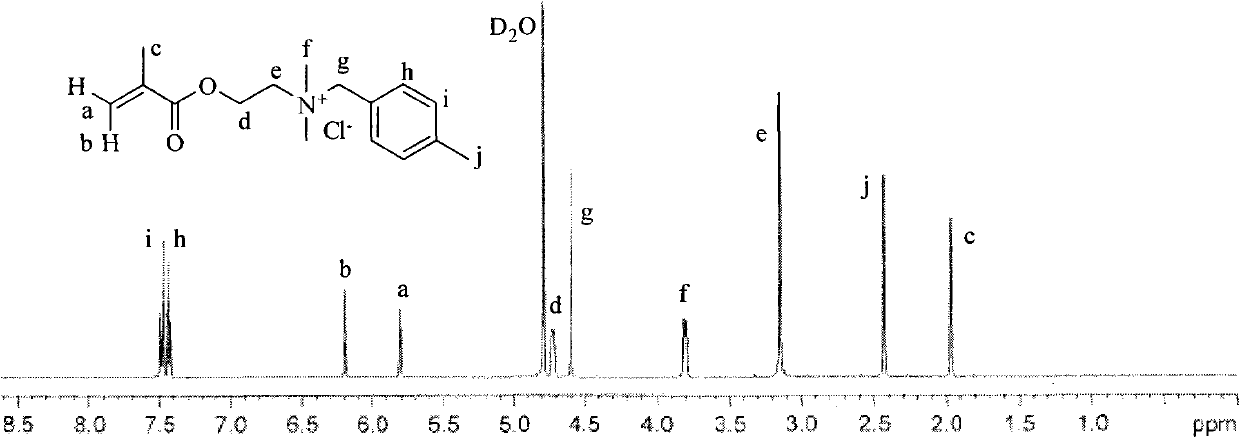

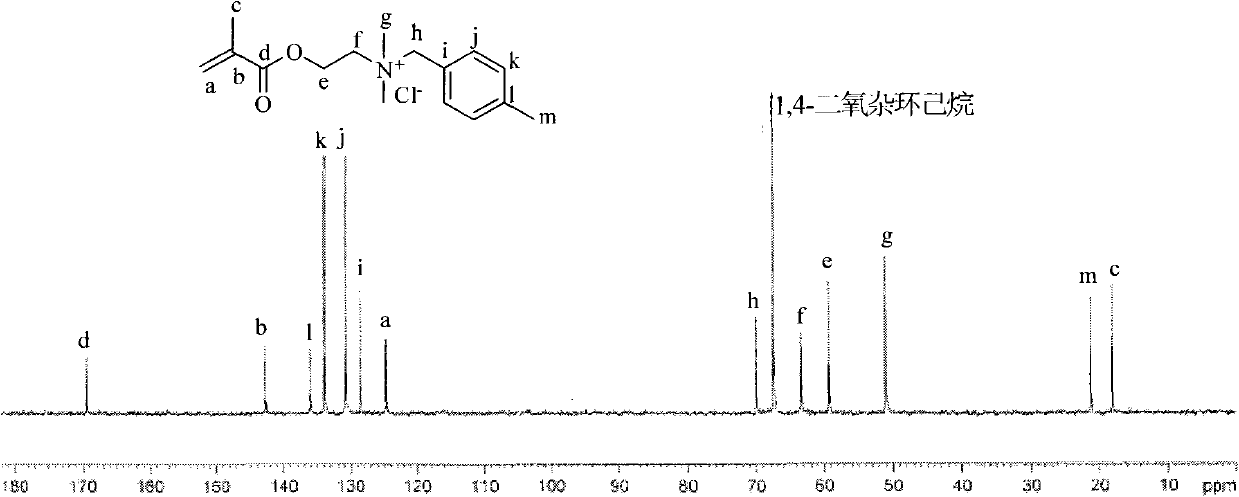

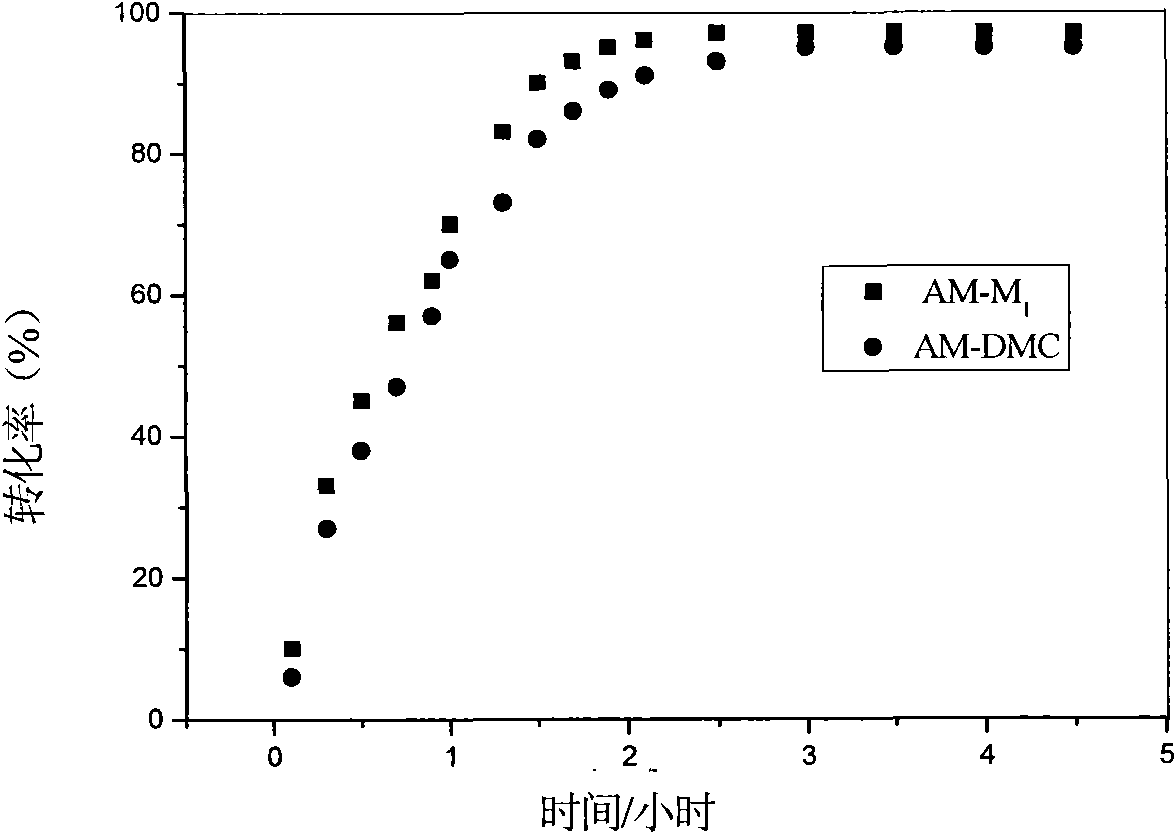

[0044] (1) Cationic polymerizable surfactant monomer (M 1 ) preparation

[0045] In a 1000ml reaction device, add 300ml of solvent acetone, 1.0mol of p-methylbenzyl chloride (about 140ml), and then dropwise add 1.5mol of dimethylaminoethyl methacrylate (purchased from Beijing Chemical Reagent Company) to the reaction system (about 240ml), after the dropwise addition, the reaction system was reacted for 20 hours under the reaction condition of 20°C. The reaction system was cooled to 0°C, and a white solid precipitated after standing overnight. Filter the gained solid and wash with acetone (200 milliliters 3 times), after freeze-drying treatment at 0 ℃ for 10 hours, obtain the quaternary ammonium salt M of white target product p-methylbenzyl chloride 1 , yield 84.9%. The product has been ide...

Embodiment 2

[0051] This example is used to illustrate the benzyl group-containing cationic polymerizable surfactant monomer and its preparation method and ionic copolymer of the present invention.

[0052] (1) Cationic polymerizable surfactant monomer (M 2 ) preparation

[0053]In a 1000ml reaction device, add 200ml of solvent dimethylacrylamide, 1.0mol of p-tert-butylbenzyl bromide (solid), and then dropwise add diethylaminoethyl acrylate (purchased from Beijing Chemical Reagent Company) to the reaction system 1mol (about 170ml). After the dropwise addition, the reaction system was reacted at 55° C. for 8 hours. The reaction system was cooled to 5°C, and a white solid precipitated out after standing overnight. The resulting solid was filtered and washed 3 times (200ml) with dimethylacrylamide, and after freeze-drying at 0°C for 10 hours, the white target product, the quaternary ammonium salt M of p-tert-butylbenzyl bromide, was obtained. 2 ; Yield 66.9%. The product has been identif...

Embodiment 3

[0057] This example is used to illustrate the benzyl group-containing cationic polymerizable surfactant monomer and its preparation method and ionic copolymer of the present invention.

[0058] (1) Cationic polymerizable surfactant monomer (M 3 ) preparation

[0059] In the reaction device of 2000ml, add solvent dichloromethane 400ml, p-n-hexyl benzyl chloride 1.0mol (solid), then dropwise add diethylaminoethyl methacrylate (purchased from Beijing Chemical Reagent Company) 5mol in the reaction system (about 950ml). After the dropwise addition, the reaction system was reacted at 35° C. for 16 hours. The reaction system was cooled to 0°C, and a white solid precipitated after standing overnight. The obtained solid was filtered and washed 3 times with dichloromethane (200ml), and after freeze-drying at 0°C for 10 hours, the white target product p-n-hexylbenzyl quaternary ammonium chloride M was obtained. 3 ; Yield 78.9%. The product was identified by infrared and nuclear magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com