Hydrothermal synthesis method of zinc borate whisker

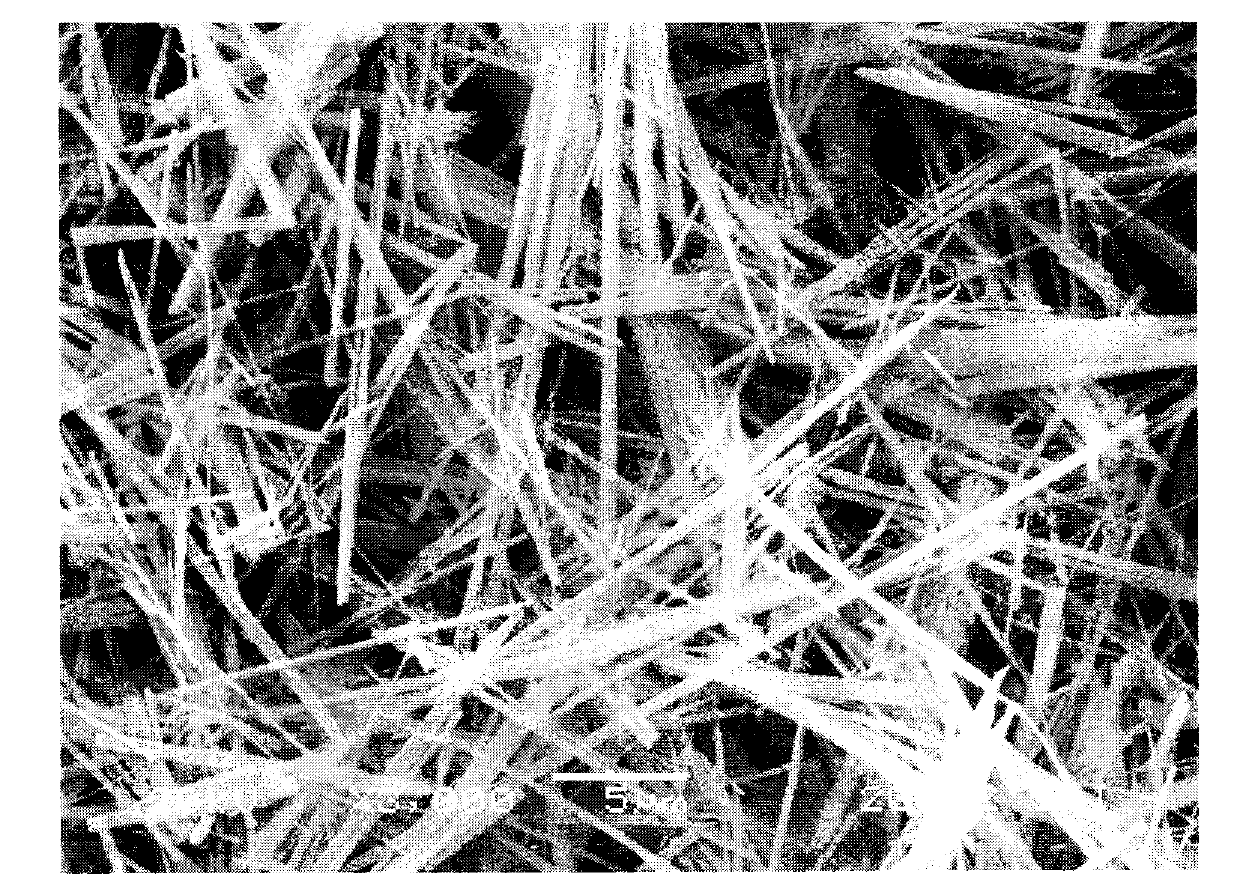

A technology of hydrothermal synthesis and zinc borate, which is applied in the directions of borates, zinc compounds, boron oxide compounds, etc., can solve the problems of complicated follow-up treatment of mother liquor, and achieves easy control of morphology, simple recovery process and good microscopic appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

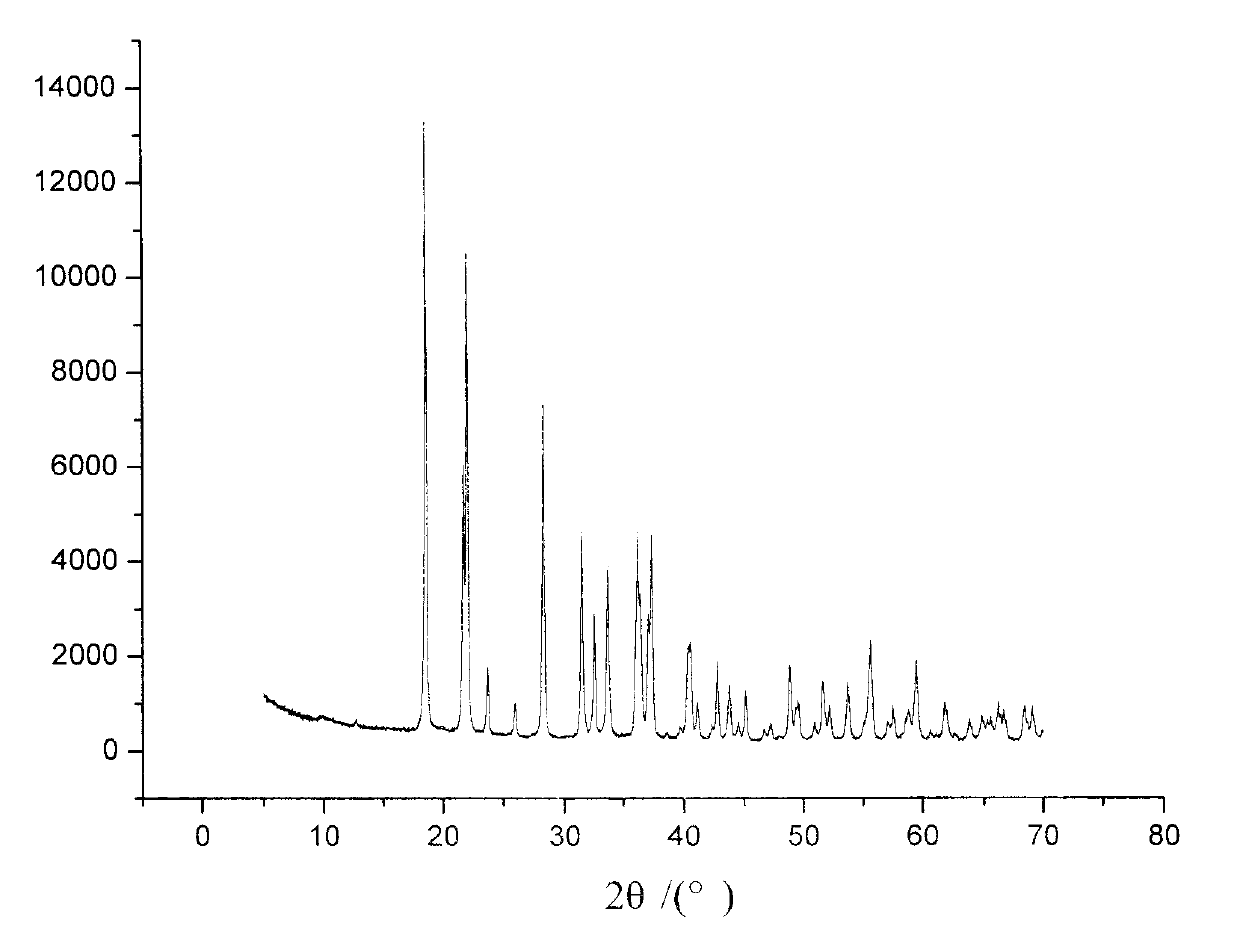

[0019] Embodiment 1 Zinc borate whisker hydrothermal synthesis new method, this method refers to that at first borax is mixed with the solution that mass percent concentration is 4.25% in the there-necked bottle of 0.5L; Then, in this solution, add mass percent concentration It is 33.0% zinc sulfate solution, adjust the mol ratio of zinc sulfate and borax to be 1.6: 1, obtain the slurry after stirring evenly; Secondly, place the slurry in a 0.5L reactor, and adjust the filling degree in the reactor to 70 %, at the same time, the reaction kettle was heated to 120°C, and after a constant temperature reaction for 16 hours, it was cooled to room temperature to obtain a white precipitate, which was aged for 8 hours and then sampled; finally, the precipitate was filtered and washed until no other ions existed, and then the Dry at 70°C for 5 hours to obtain zinc borate whisker powder.

Embodiment 2

[0020] Embodiment 2 The new method of hydrothermal synthesis of zinc borate whiskers, this method refers to that first borax is mixed with the solution that the mass percent concentration is 3.75% in the there-necked bottle of 0.5L; Then, in this solution, add the mass percent concentration Be 35.2% zinc nitrate solution, adjust the mol ratio of zinc nitrate and borax to be 2: 1, obtain slurry after stirring; Next, place slurry in 0.5L reactor, and adjust the filling degree in the reactor to 70 %, at the same time, the temperature of the reactor was raised to 160°C, and after constant temperature reaction for 1 hour, it was cooled to room temperature to obtain a white precipitate. Dry at 90°C for 4 hours to obtain zinc borate whisker powder.

Embodiment 3

[0021] Embodiment 3 The new method of hydrothermal synthesis of zinc borate whiskers, this method refers to that at first borax is mixed with the solution that the mass percent concentration is 3.46% in the there-necked bottle of 0.5L; Then, in this solution, add the mass percent concentration It is 20.9% zinc chloride solution, adjust the molar ratio of zinc chloride and borax to be 2.2: 1, obtain the slurry after stirring evenly; secondly, place the slurry in a 0.5L reactor, and adjust the filling degree in the reactor At the same time, the temperature of the reaction kettle was raised to 110°C, and after constant temperature reaction for 20 hours, it was cooled to room temperature to obtain a white precipitate, which was aged for 10 hours and then sampled; finally, the precipitate was filtered and washed until no other ions existed. , and dried at 80°C for 5 hours to obtain zinc borate whisker powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com