Preparation method of dendrimer stable bismuth sulfide nanoparticles

A technology of dendrimer and amine dendrimer, applied in the field of preparation of bismuth sulfide nanoparticles, can solve problems such as no related reports, and achieve the effect of preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

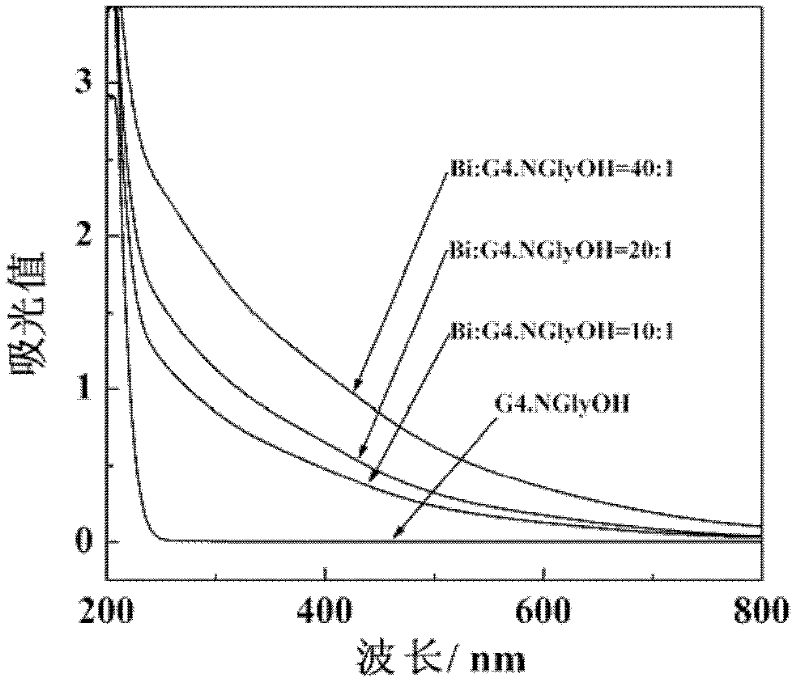

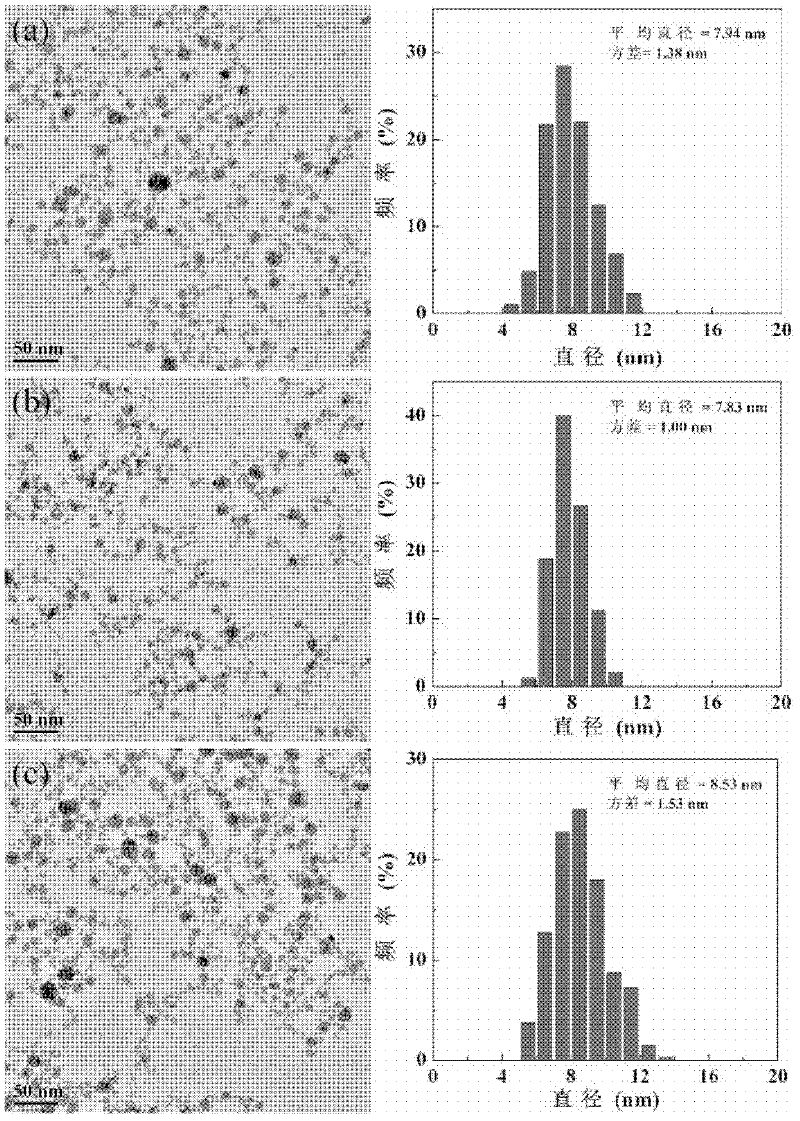

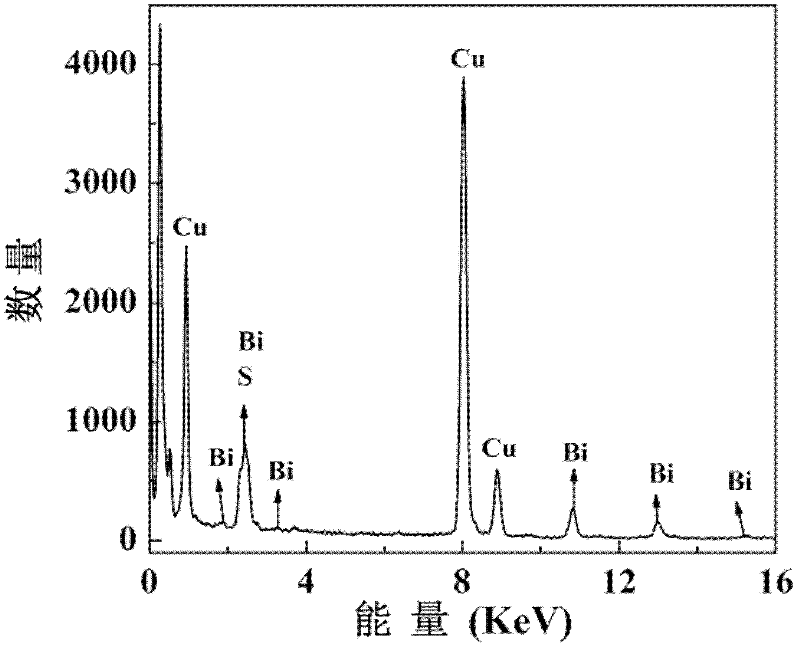

[0054] (1) Prepare 25 mL of dilute acetic acid solution with a volume fraction of 10%. The fourth generation polyamidoamine dendrimer (G4.NGlyOH) with a dry weight of 40.00 mg at the end of the hydroxyl group was dissolved in 8 mL of 10% dilute acetic acid solution, and ultrasonically treated to make it fully dissolved and uniform. Take Bi(NO 3 ) 3 ·5H 2 10.68mg of O powder was dissolved in 5.34mL of 10% dilute acetic acid solution, ultrasonically treated to fully dissolve it, and then added to the G4.NGlyOH solution, stirred for 1 hour, and the two were fully mixed.

[0055] (2) Take Na 2 S·9H 2 O solid 2g, dropwise adding therein is the dilute acetic acid solution of 10% by volume fraction, the H produced 2 S gas was continuously fed into the solution in step (1), and the reaction was stirred at room temperature for 1 h under the condition of nitrogen protection. After the reaction was completed, the stirring was continued for 8 h, and then the reaction product was dia...

Embodiment 2

[0060] (1) Prepare 25 mL of dilute acetic acid solution with a volume fraction of 10%. The fourth-generation polyamidoamine dendrimer (G4.NGlyOH) with a dry weight of 30.00 mg at the end of the hydroxyl group was dissolved in 10 mL of 10% dilute acetic acid solution, and ultrasonically treated to fully dissolve it evenly. Take Bi(NO 3 ) 3 ·5H 2O powder 16.02mg, dissolved in 10.68mL of 10% dilute acetic acid solution, ultrasonic treatment to make it fully dissolved, then added to G4.NGlyOH solution, stirred for 1.5h, so that the two were fully mixed.

[0061] (2) will Bi(NO 3 ) 3 ·5H 2 O1.5 times the amount of substance H 2 S gas was continuously fed into the solution in step (1), and the reaction was stirred at room temperature for 1.5 h under the condition of nitrogen protection. After the reaction was completed, the stirring was continued for 9 h, and then the reaction product was dialyzed 3 times in 4 L of PBS buffer solution and 3 times in 4 L of ultrapure water wit...

Embodiment 3

[0066] (1) Prepare 25 mL of dilute acetic acid solution with a volume fraction of 10%. 20.00 mg of the fourth-generation polyamidoamine dendrimer (G4.NGlyOH) with a hydroxyl terminal at the end was dissolved in 2.86 mL of 10% dilute acetic acid solution, and ultrasonically treated to make it fully dissolved and uniform. Take Bi(NO 3 ) 3 ·5H 2 21.36mg of O powder was dissolved in 8.54mL of 10% dilute acetic acid solution, sonicated to make it fully dissolved and uniform, then added to the G4.NGlyOH solution, stirred for 2 hours, and the two were fully mixed.

[0067] (2) Take Na 2 S·9H 2 O solid 2.5g, wherein dropwise adding is the dilute acetic acid solution of 20% volume fraction, the H produced 2 S gas was continuously fed into the solution in step (1), and the reaction was stirred at room temperature for 2 h under the condition of nitrogen protection. After the reaction was completed, the stirring was continued for 9 h, and then the reaction product was dialyzed 3 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com