Water-dispersible granules of emamectin benzoate

A technology of emamectin and benzoate, applied in the direction of insecticides, biocides, animal repellents, etc., to achieve the effects of improving drug efficacy, reducing solvent costs, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

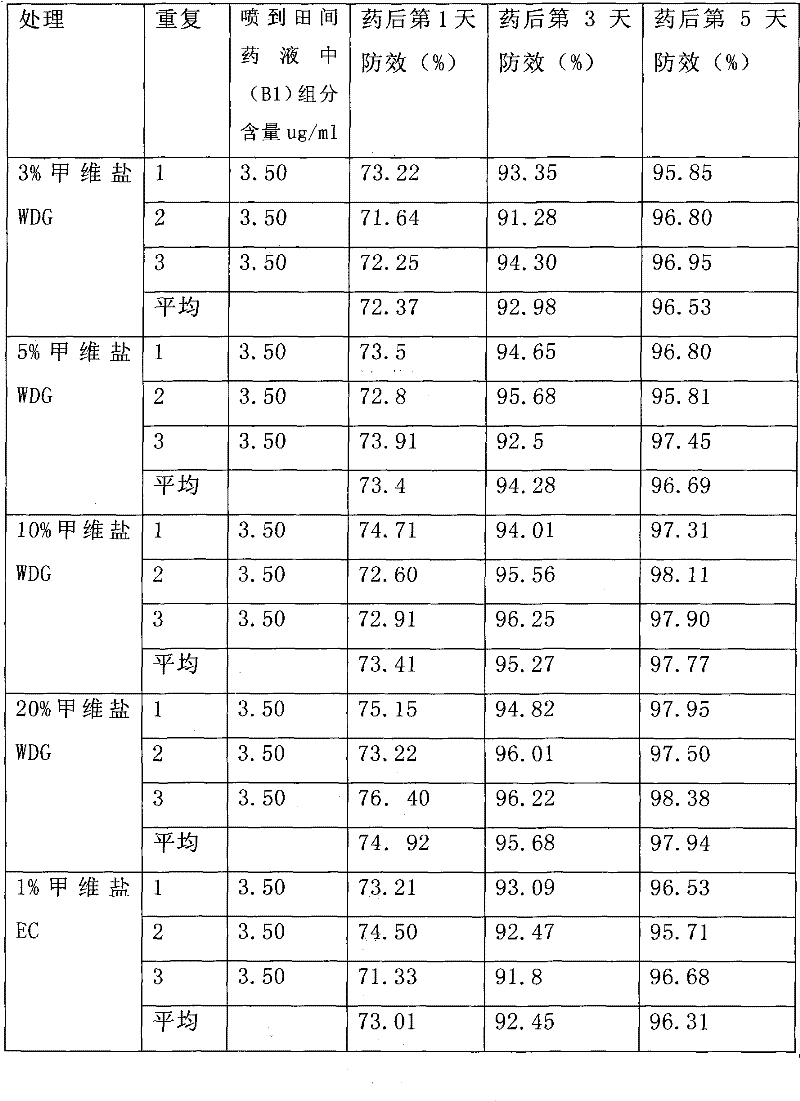

Examples

Embodiment 1

[0014] Emamectin benzoate 5% WDG: emamectin 5.0%, polycondensed naphthalene sulfonate 15.0%, sodium lauryl sulfate 5.0, ammonium sulfate 37.0%, starch 35.0%, epoxy soybean oil 3.0 %, according to the above weight ratio, first weigh the original drug of emamectin benzoate, polycondensed naphthalene sulfonate, sodium lauryl sulfate, ammonium sulfate, starch and epoxy soybean oil and add them to the feeding kettle. Thoroughly mix evenly, and then pulverize by jet mill, then mix again, and then pulverize into wettable powder by superfine pulverizer. Then add the prepared wettable powder and appropriate amount of water into a kneader for kneading to make a plastic material suitable for granulation, and put it into a press granulator for extrusion granulation. Then the extruded particles are fully dried, and then shaped and sieved after drying. After sieving, a product with a qualified particle size is obtained, and then the product is tested and analyzed. Its physical and chemical ...

Embodiment 2

[0022] Emamectin benzoate 3% WDG: emamectin 3.0%, sodium methylene bis-naphthalene sulfonate 8.0%, calcium alkylbenzene sulfonate 6%, sodium lauryl sulfate 6.0%, sulfuric acid Sodium 35.0%, starch 39.0%, epichlorohydrin 3.0%, the former drug of emamectin benzoate, sodium methylene bis-naphthalene sulfonate, sodium lauryl sulfate, sodium sulfate, starch and epoxy The chloropropane is weighed and added to the feeding kettle, fully mixed evenly in the twin-screw stirring tank, pulverized by a jet mill, then mixed, and then pulverized into a wettable powder by an ultrafine pulverizer. Then add the prepared wettable powder and appropriate amount of water into a kneader for kneading to make a plastic material suitable for granulation, and put it into a press granulator for extrusion granulation. Then fully dry the extruded particles, shape and sieve after drying, and obtain a product with a qualified particle size after sieving, and then test and analyze the product. Its physical an...

Embodiment 3

[0030] Emamectin benzoate 10% WDG: emamectin 10.0%, phenethylphenol polyoxyethylene sodium sulfate 10.0%, alkyl naphthalene sulfonate condensation polymer 8.0%, bentonite 24.0%, hexametaphosphoric acid Sodium sodium 5.0%, kaolin 40.0%, epoxy linseed oil 3.0%, the former drug of emamectin benzoate, phenylethylphenol polyoxyethylene sodium sulfate, alkylnaphthalene sulfonate polycondensate, bentonite, cyclic Oxygenated linseed oil, sodium hexametaphosphate and kaolin are weighed and added to the feeding kettle, fully mixed evenly through the twin-screw stirring tank, then pulverized by the jet mill, and then mixed, and then pulverized by the superfine pulverizer into wettable powder. Then add the prepared wettable powder and appropriate amount of water into a kneader for kneading to make a plastic material suitable for granulation, and put it into a press granulator for extrusion granulation. Then the extruded particles are fully dried, shaped and sieved after drying, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com