A preparation method of coated pure silicon mesoporous MSU-1 molecular sieve membrane core-shell catalyst

A MSU-1, molecular sieve technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of alkali-resistance composite collector plate

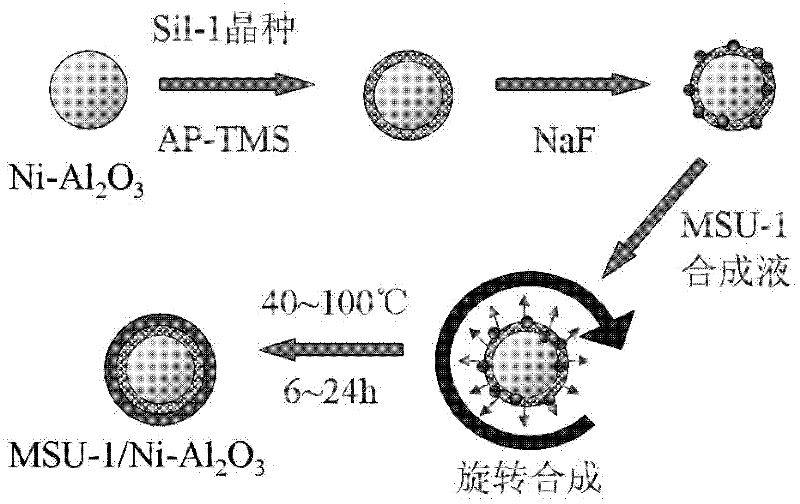

[0029] (1) Preparation of pure silicon molecular sieve seed crystals and their covalent coupling with carriers

[0030] According to TPAOH:SiO 2 :H 2 O=25:100:2700 molar ratio to prepare Sil-1 molecular sieve seed crystal synthesis precursor solution, wherein tetrapropylammonium hydroxide (TPAOH) and deionized water are used as silicon source, tetrapropylammonium hydroxide (TPAOH) and deionized water , fully mixed and stirred at room temperature for 24 hours, poured into a stainless steel crystallization kettle lined with polytetrafluoroethylene, sealed and placed in an oven at 100°C, and taken out after 15 hours; the obtained mixed solution was centrifuged and washed with deionized water Wash it repeatedly to neutrality, and then replace it with ethanol solution to obtain Sil-1 molecular sieve seed crystals with a particle size of 150-200nm, prepare it into an ethanol suspension with a mass fract...

Embodiment 2

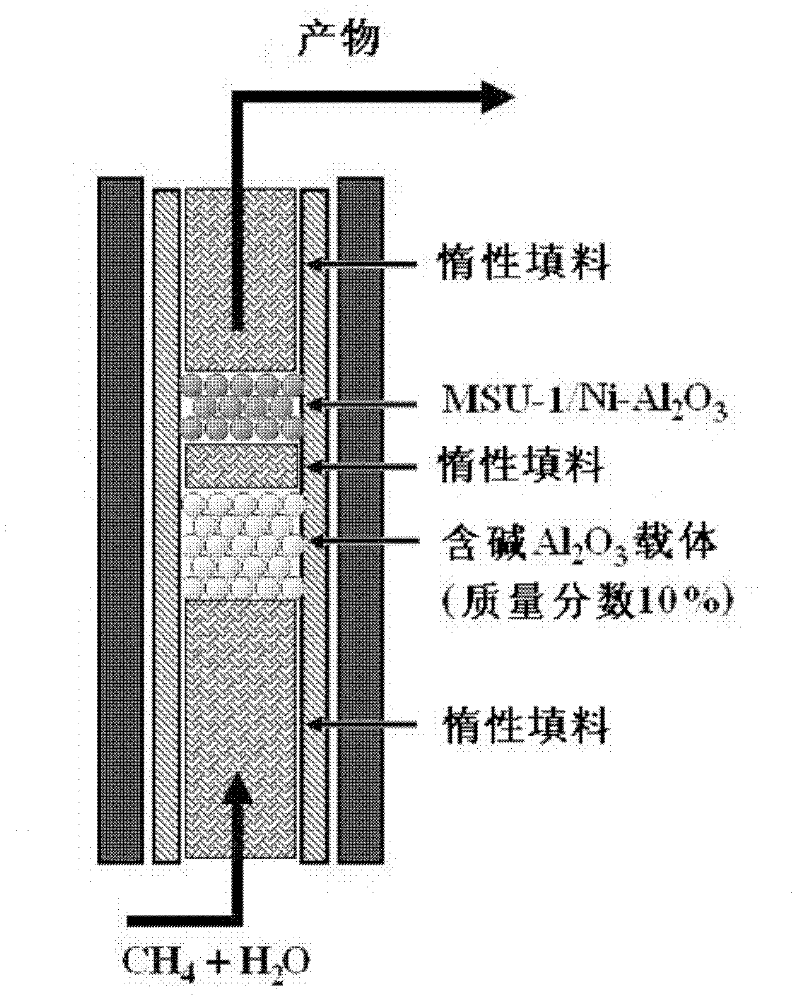

[0036] Example 2: MSU-1 / Ni-Al 2 o 3 Test of catalyst anti-alkali poisoning performance

[0037] The test reactor adopts a stainless steel tube (inner diameter 6mm, length 400mm), ceramic inert packing is placed at the bottom of the reactor first, and then the original catalyst and MSU-1 / Ni-Al 2 o 3 The catalyst (500-1000 mg) is placed on the packing layer (quartz wool pad) so that the catalyst layer is in the constant temperature zone of the heating furnace, and the alkali (Li 2 CO 3 with K 2 CO 3 Molar ratio is 62: 38) impregnated inert packing layer (the mass fraction of alkali concentration is 20%) is placed on the catalyst bed layer; Before reaction system feeds hydrogen (20ml / min) to carry out catalyst reduction 2~4h, according to CH 4 / H 2 O ratio 3: 1 from the upper port of the reactor (25ml: 75ml), control reaction temperature 650 ℃, gas chromatography (GC7890, TCD detector) online sampling detection H 2 , CO, CO 2 and CH 4 Component content.

Embodiment 3

[0038] Example 3: Stability test of MSU-1 molecular sieve membrane loaded on the carrier surface

[0039] MSU-1 / Ni-Al prepared without seed induction method and with seed induction method 2 o 3 The catalysts were put into the crucible together, and baked in a muffle furnace at 650°C for 10-15 hours, and the stability of the MSU-1 molecular sieve membrane loading and binding on the carrier surface could be judged by the shedding of the membrane layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com