A kind of preparation method of double-structure suede transparent conductive electrode

A technology of transparent conductive electrodes and transparent conductive films, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of pollution, difficult to ensure the yield of industrial production, difficult CIGS co-deposition process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

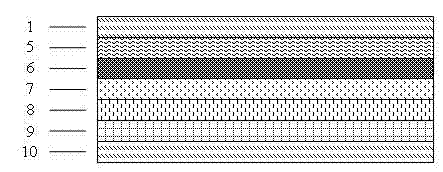

Image

Examples

Embodiment Construction

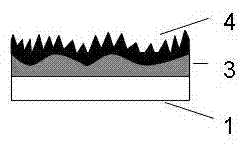

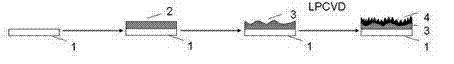

[0023] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0024] A method for preparing a double-structure suede transparent conductive electrode, the specific manufacturing process is as follows:

[0025] ①Firstly, send the ultra-clear float glass substrate to be coated into the glass cleaning machine for cleaning, then send the clean ultra-clear float glass substrate 1 into the magnetron sputtering machine, and the background vacuum of the coating chamber reaches 2× 10 -4 Pa, in a high-purity argon environment of 0.3Pa, a TCO transparent conductive film 2 is deposited on a glass substrate by magnetron sputtering, the substrate temperature is 150°C, and the thickness of the deposited film is 1000nm;

[0026] ②The prepared TCO transparent conductive film 2 is wet-etched, using dilute hydrochloric acid as the etching solution, the concentration is 0.5%, the temperature is 20°C, the etching time is 45s,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com