Connecting method of C/C composite material and copper or copper alloy

A composite material and connecting method technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex preparation method of active coating, high heat treatment temperature, low joint strength, etc., and achieve simple introduction method and bonding strength. High, high joint strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

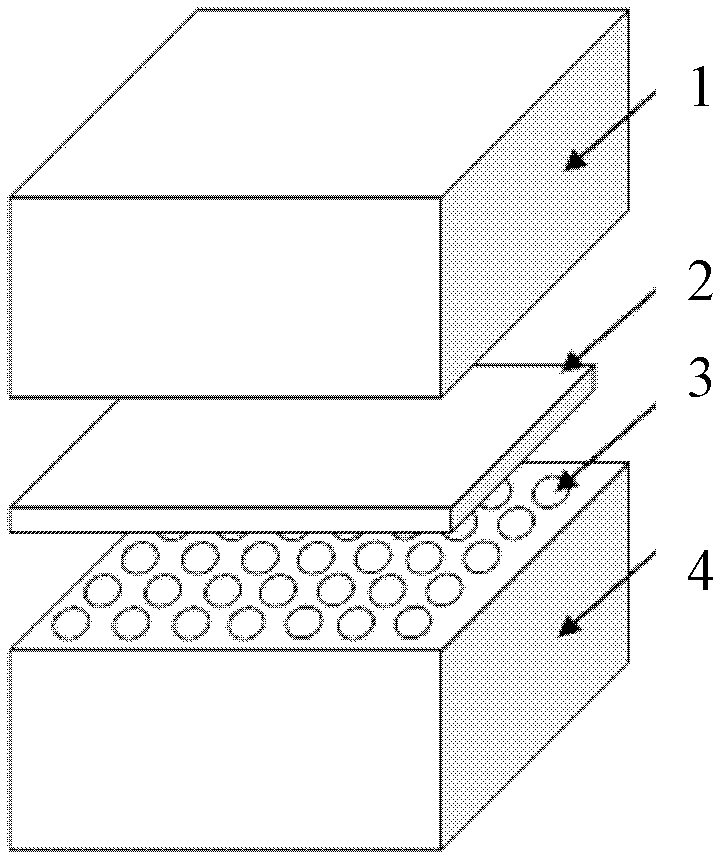

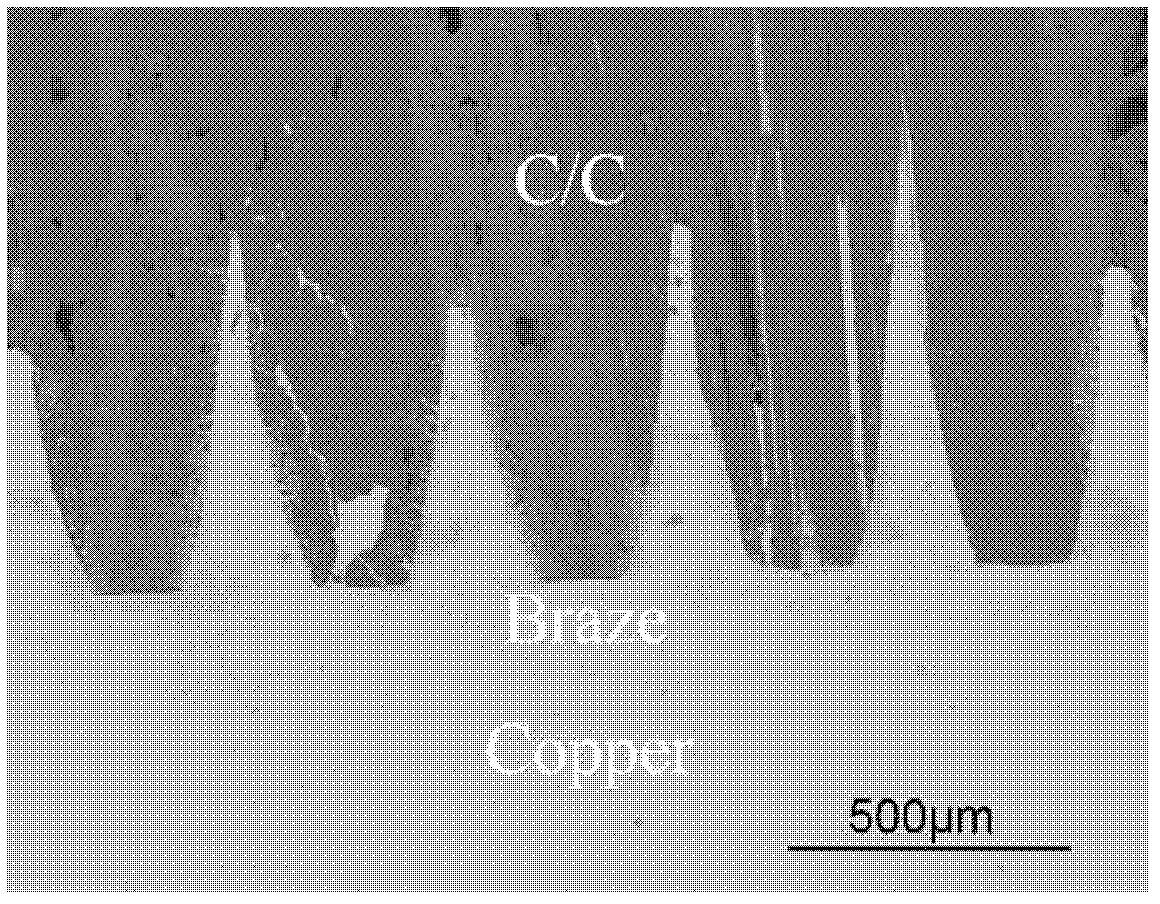

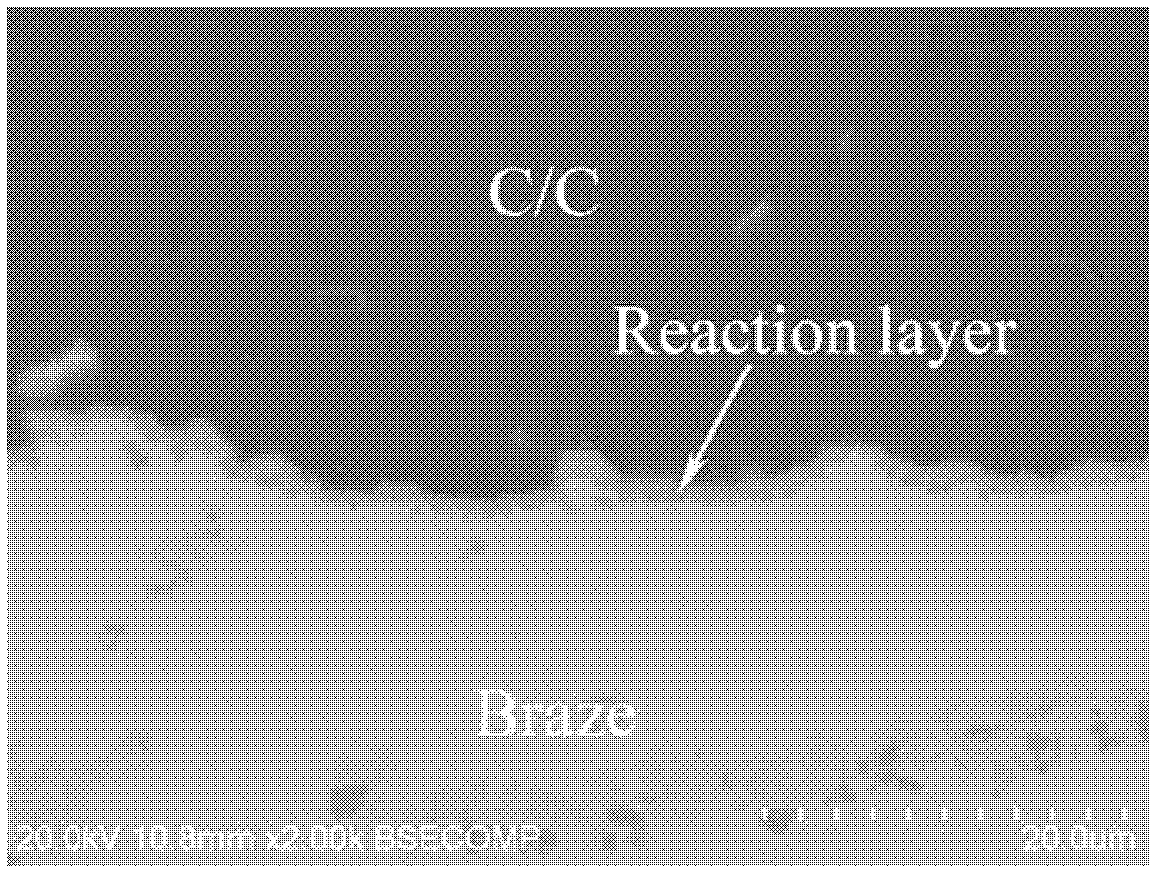

[0024] The invention forms a layered transition reaction layer through the physical and chemical reaction of active elements on the surface of the C / C composite material, improves the wettability of the solder and forms a strong interface bond, and realizes the tight connection between the C / C composite material and copper. in:

[0025] 1. The C / C composite material is cut into 15mm×10mm×5mm, and the welding surface is punched and roughened by laser technology. After processing, use TiH 2 Powder (powder particle size 2 Coating, the coating thickness is 40 μm. The thickness of Cu-3.5Si solder foil is 200μm, and the oxygen-free pure copper is processed into 15mm×10mm×5mm.

[0026] 2. Assemble the C / C composite material, Cu-3.5Si solder and oxygen-free pure copper into a sandwich structure in the order of "C / C-solder-copper" and place it in the brazing furnace. When the vacuum reaches 2×10 -3 Pa~5×10 -3 At Pa, heat up to a welding temperature of 1050-1070°C and keep it warm f...

Embodiment 2

[0034] The difference from Example 1 is that

[0035] 1. The C / C composite material is cut into 15mm×10mm×5mm, and the welding surface is punched and roughened by laser technology. After the processing is completed, the surface of C / C is treated with titanium metallization by magnetron sputtering method, and a uniform Ti coating is formed on the surface of C / C with a thickness of 10 μm. The thickness of Cu-3.5Si brazing filler metal foil is 200μm, and the CuCrZr alloy is cut into a size of 16mm×11mm×7mm. In the CuCrZr alloy, by weight percentage, Cr: 0.25-0.65, Zr: 0.08-0.20, and the rest is Cu.

[0036] 2. Assemble the C / C composite material Cu-3.5Si solder and CuCrZr alloy into a sandwich structure in the order of "C / C-solder-copper alloy" and place it in the brazing furnace. When the vacuum reaches 2×10 -3 Pa~5×10 -3 At Pa, heat up to a welding temperature of 1050-1070°C and keep it warm for 5-20 minutes to complete brazing. After the brazing is completed, the temperatur...

Embodiment 3

[0040] The difference from Example 1 is that

[0041] On the basis of the C / C composite material and oxygen-free copper joint (CC / Cu joint, Cu thickness 2mm) obtained in Example 1, the CC / Cu joint and CuCrZr alloy were connected by diffusion welding to obtain a CC / Cu / CuCrZr joint.

[0042] The process parameters of diffusion welding connection are as follows:

[0043] Diffusion welding connection temperature 600~800℃, connection pressure 5~10MPa, connection time 10~60min, vacuum degree 2×10 -3 Pa.

[0044] The performance test of CC / Cu / CuCrZr joints shows that the shear strength at room temperature is as high as 79MPa, and the joint interface remains intact after 50 thermal cycles at 450°C thermal shock test (water quenching), and no interface cracks and peeling off phenomena are found. Excellent shock performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com