A method for increasing the yield of fluorine-containing alkyl ethanol

A fluorine-containing alkyl ethyl and alkyl ethanol technology is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., to achieve the effects of short reaction time, reduced production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

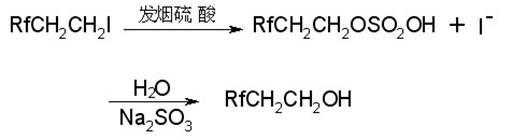

Image

Examples

preparation example Construction

[0022] Preparation of perfluoroalkylethyl iodide:

[0023] Add 4000g of perfluorohexyl iodide, 500g of sodium hydrosulfate, 200g of sodium bicarbonate, and 25g of sodium carbonate into a 10L stainless steel pressure-resistant reactor. Vacuumize and replace with high-purity nitrogen for 3 times. Add 1500ml of pure water and 3000ml of acetonitrile under negative pressure. Start stirring, heat up to 60°C, and continuously add ethylene. After 6 hours, the ethylene pressure in the kettle stopped dropping, and the reaction material was released, and the organic phase was separated to obtain 4880 g, with a theoretical purity of 87%.

[0024] The same method was used to prepare perfluorooctylethyl iodide with a theoretical purity of 82%.

Embodiment 1

[0026] In a 500ml four-necked flask, add 800g of prepared perfluorohexylethyl iodide, configure a water separator, a condenser, and a negative pressure device on the upper part, raise the temperature to 70-80°C, and control the negative pressure at -0.6-0.8MPa, And constantly put the raw materials brought out back into the kettle. After continuing for 4 hours, there is no longer obvious water to evaporate, and the operation is stopped, and the remaining 695g of the kettle material.

[0027] Add 600g of 20% fuming sulfuric acid in a 2L glass bottle, stir, then add 78.5g of perfluorohexylethyl iodide prepared within 1.5 hours, continue to insulate and stir for 60 minutes after adding to obtain a reaction solution; In a 2000ml flask cooled by a water bath, add 20g of sodium sulfite and 750ml of pure water, stir to dissolve. Slowly pour the black reaction solution into it, replace the heating mantle, start heating to reflux, and keep reflux for 1 hour; stop heating, replace the w...

Embodiment 2

[0031] According to the method, operation steps and process conditions of Example 1, perfluorooctyl ethyl iodide was used to prepare perfluorooctyl ethanol, and the raw materials and usage amounts listed in Table 1 were fed.

[0032] Table 1 Raw Material Feeding Table

[0033] Feeding raw material name Amount added A Perfluorooctylethyl iodide 170g B 25% oleum 750g C Na 2 SO 3 40g D Deionized water 1500ml

[0034] Finally, 115 g of perfluorooctyl ethanol was prepared with a yield of 83.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com