A kind of modified coal tar pitch material and its preparation method and application

A coal tar pitch and modification technology, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of long reaction time, lower temperature, high coking value, etc., and achieve controllable reaction and processing time and low benzopyrene content Reduce and avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

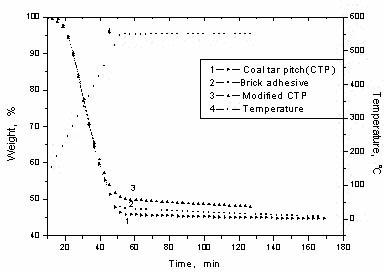

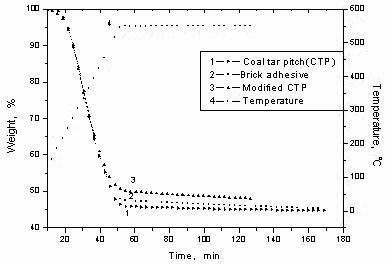

Image

Examples

Embodiment 1

[0027] A modified coal tar pitch material, calculated in parts by weight, its component composition and the parts by weight of the contained components are as follows:

[0028] Raw coal tar pitch 100 parts

[0029] 100 parts of water

[0030] Stabilizer 0.2 parts

[0031] Fenton's reagent 9.089 parts

[0032] The raw coal tar pitch is medium temperature coal tar pitch;

[0033] The stabilizing agent is gelatin;

[0034] The Fenton's reagent refers to an oxidizing reagent prepared from hydrogen peroxide and ferrous salt; the molar ratio of hydrogen peroxide to ferrous salt in the Fenton's reagent, that is, hydrogen peroxide:ferrous salt is 1:1 ; Described ferrous salt is ferrous sulfate.

[0035] The preparation method of above-mentioned a kind of modified coal tar pitch material, step is as follows:

[0036] Pour medium-temperature coal tar pitch (produced by Henan Pingmei Group, softening point 85°C, benzopyrene content 1.5%) into a mortar, grind and sieve through 80 me...

Embodiment 2

[0038] A modified coal tar pitch material, calculated in parts by weight, its component composition and the parts by weight of the contained components are as follows:

[0039] Raw coal tar pitch 100 parts

[0040] 100 parts of water

[0041] Stabilizer 0.2 parts

[0042] Fenton's reagent 11.134 parts

[0043] The raw coal tar pitch is medium temperature coal tar pitch;

[0044] The stabilizing agent is gelatin;

[0045] The Fenton's reagent refers to an oxidizing reagent prepared from hydrogen peroxide and ferrous salt; the molar ratio of hydrogen peroxide to ferrous salt in the Fenton's reagent, that is, hydrogen peroxide:ferrous salt is 1:1.5 ; Described ferrous salt is ferrous sulfate.

[0046] The preparation method of above-mentioned a kind of modified coal tar pitch material, step is as follows:

[0047] Pour medium-temperature coal tar pitch (produced by Henan Pingmei Group, softening point 85°C, benzopyrene content 1.5%) into a mortar, grind and sieve through 80...

Embodiment 3

[0049] A modified coal tar pitch material, calculated in parts by weight, its component composition and the parts by weight of the contained components are as follows:

[0050] Raw coal tar pitch 100 parts

[0051] 100 parts of water

[0052] Stabilizer 0.2 parts

[0053] Fenton's reagent 13.178 parts

[0054] The raw coal tar pitch is medium temperature coal tar pitch;

[0055] The stabilizing agent is gelatin;

[0056]The Fenton's reagent refers to an oxidizing reagent prepared from hydrogen peroxide and ferrous salt; the molar ratio of hydrogen peroxide to ferrous salt in the Fenton's reagent, that is, hydrogen peroxide:ferrous salt is 1:2 ; Described ferrous salt is ferrous sulfate.

[0057] The preparation method of above-mentioned a kind of modified coal tar pitch material, step is as follows:

[0058] Pour medium-temperature coal tar pitch (produced by Henan Pingmei Group, softening point 85°C, benzopyrene content 1.5%) into a mortar, grind and sieve through 80 me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com