Catalyst for preparing styrene from ethylbenzene dehydrogenation and preparation method thereof

A technology for ethylbenzene dehydrogenation production and catalyst, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., and can solve the problems of time-consuming, long synthesis cycle and raw material cost high problems, to achieve the effects of easy control of reaction conditions, cheap synthetic raw materials and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

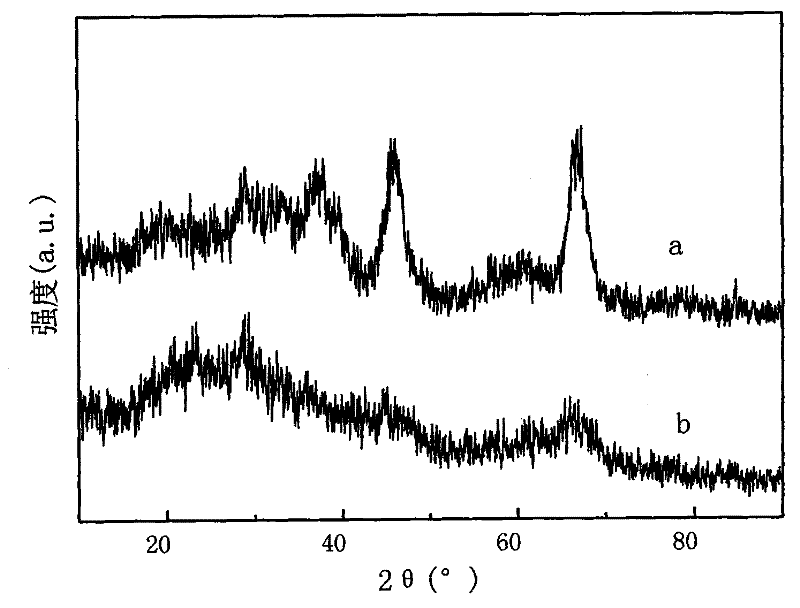

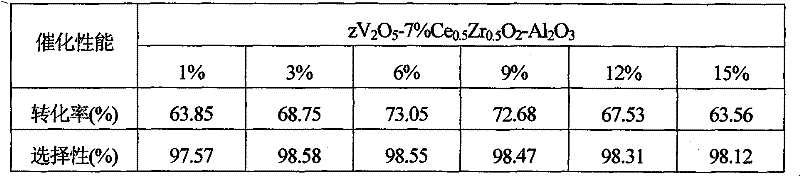

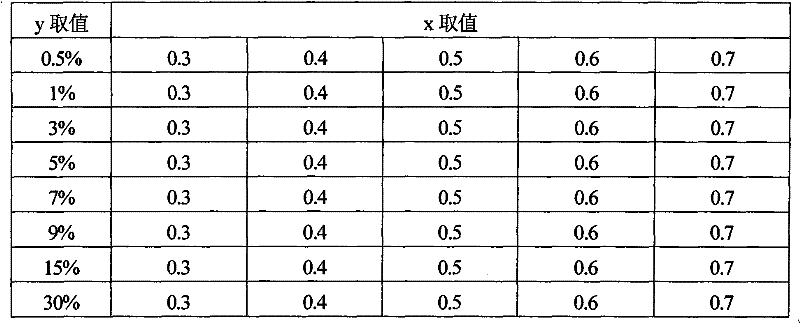

[0020] To prepare the general formula as zV 2 o 5 -yCe x Zr 1-x o 2 -Al 2 o 3 For example, x is the number of moles of Ce atoms in the formula, y is the mass percentage of cerium-zirconium solid solution in cerium-zirconium-aluminum composite oxide, and z is V 2 o 5 The mass percentage in the catalyst, the value of x is 0.5, the value of y is 7%, the value of z is 6%, and its preparation method is as follows:

[0021] Add 14.5 g of polyethylene glycol with an average molecular weight of 5000 to 7000, 0.3390 g of cerous nitrate hexahydrate, 0.2929 g of zirconium nitrate pentahydrate, 22.5 g of aluminum nitrate nonahydrate, 0.2741 g of ammonium metavanadate, and 0.2741 g of ammonium metavanadate into 150 mL of distilled water. Oxalic acid 0.1476g, the molar ratio of oxalic acid dihydrate and ammonium metavanadate is 1:2, stir until the solid dissolves, adjust the pH value to 9.5-11.0 with ammonia water, continue stirring for 2-4 hours, transfer to the hydrothermal reactio...

Embodiment 2

[0024] To prepare the general formula as zV 2 o 5 -yCe x Zr 1-x o 2 -A1 2 o 3 For example, x is the number of moles of Ce atoms in the formula, y is the mass percentage of cerium-zirconium solid solution in cerium-zirconium-aluminum composite oxide, and z is V 2 o 5 In the mass percentage in the catalyst, the value of x is 0.3, the value of y is 1%, and the value of z is 6%. Its preparation method is as follows:

[0025] Add 14.5 g of polyethylene glycol with an average molecular weight of 5000 to 7000, 0.0292 g of cerous nitrate hexahydrate, 0.0589 g of zirconium nitrate pentahydrate, 22.5 g of aluminum nitrate nonahydrate, 0.2544 g of ammonium metavanadate, and 0.2544 g of ammonium metavanadate into 150 mL of distilled water. 0.1370 g of oxalic acid, the molar ratio of oxalic acid dihydrate to ammonium metavanadate is 1:2, and other steps are the same as in Example 1 to prepare a catalyst.

Embodiment 3

[0027] To prepare the general formula as zV 2 o 5 -yCe x Zr1-x o 2 -Al 2 o 3 For example, x is the number of moles of Ce atoms in the formula, y is the mass percentage of cerium-zirconium solid solution in cerium-zirconium-aluminum composite oxide, and z is V 2 o 5 The mass percentage in the catalyst, the value of x is 0.4, the value of y is 3%, the value of z is 6%, and its preparation method is as follows:

[0028] Add 14.5 g of polyethylene glycol with an average molecular weight of 5000 to 7000, 0.1153 g of cerous nitrate hexahydrate, 0.1494 g of zirconium nitrate pentahydrate, 22.5 g of aluminum nitrate nonahydrate, 0.2562 g of ammonium metavanadate, and 0.2562 g of ammonium metavanadate into 150 mL of distilled water. 0.1379g of oxalic acid, the molar ratio of oxalic acid dihydrate to ammonium metavanadate is 1:2, and other steps are the same as in Example 1 to prepare a catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com