Positive thermo-sensitive lithographic plate precursor

A technology for lithographic printing plates and printing plates, which is applied in the field of positive-print thermal lithographic printing plate precursors, and can solve the problems of low developing latitude and poor solvent resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Synthesis of aminopropene

[0089] In a 1000ml three-necked flask, install a stirring tube, a condenser, and a dropping funnel, weigh 40g of acrylamide, add 200ml of water, add 100ml of 10% sodium hydroxide solution, add 3g of polymerization inhibitor ZJ-701, and start stirring to make The resin is completely dissolved, start to heat up to 55°C, add 250ml of sodium hypochlorite aqueous solution (13%) dropwise, drop it within half an hour, continue to react for 1 hour, cool down to room temperature and add hydrochloric acid, adjust the pH to 6, cool down to 5°C to precipitate 22g of amino propylene.

[0090] Equation 10:

[0091]

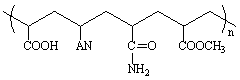

[0092] Synthesis of Acrylic Resin N1

[0093] In a 1000ml four-neck flask, install a stirring tube, a condenser tube, and a dropping funnel, feed nitrogen gas to eliminate oxygen in the bottle, add 400ml ethyl cellosolve, 0.6g dibenzoyl peroxide, and 15g of the above-mentioned aminopropylene, and start Stir to dissolve, add 8g of methacr...

Embodiment 2

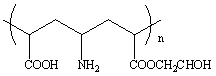

[0095] Synthesis of 2-aminoacrylic acid

[0096] In a 1000ml three-neck flask, put on top stirring, condenser, and dropping funnel, weigh 60g of maleimide, add mixed solvent (50ml of methyl cellosolve and 150ml of water), add 100ml of 10% sodium hydroxide solution , sodium ethoxide 15g, add 3g polymerization inhibitor ZJ-701, start stirring to completely dissolve the resin, start to heat up to 55°C, add 250ml of sodium hypochlorite aqueous solution (13%) dropwise, drop it within half an hour, and continue the reaction for 1 hour, Cool down to room temperature and add hydrochloric acid to adjust the pH to 6, extract with 200ml of dichloromethane, and distill off the dichloromethane to obtain 2-aminoacrylic acid.

[0097] formula 11

[0098]

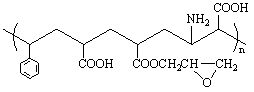

[0099] Synthesis of Acrylic Resin N2

[0100] Ethyl acrylate 20 was placed in a 1000ml four-necked flask, equipped with a stirring tube, a condenser, and a dropping funnel, fed with nitrogen gas to remove oxygen in the bottle, added 4...

Embodiment 3

[0102] Synthesis of Acrylic Resin N3

[0103] In a 1000ml four-neck flask, install a top stirrer, a condenser tube, and a dropping funnel, feed nitrogen gas to remove oxygen in the bottle, add 400ml of ethyl cellosolve, 0.6g of dibenzoyl peroxide, and 5g of the above-mentioned 2-aminopropene , start stirring to dissolve, add styrene 12, acrylic acid 8g, glycidyl methacrylate 10g, stir for 10 minutes, start to heat up to 80°C, react for 1 hour, start to drop mixed monomers (2-aminopropene 5g, methyl Dissolve 5g of glycidyl acrylate in 50ml of ethyl cellosolve), drop it within 1 hour, continue to react for 4 hours, after the reaction, cool down to room temperature, add 0.5g of hydroquinone (dissolved in 50ml of ethyl cellosolve) Cellosolve), stirred for 10 minutes, then slowly added the reaction mixture into 4 liters of water to obtain a white solid, filtered, washed three times, and dried in a vacuum drying oven to obtain the acrylic resin N3 containing the present invention. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com