A kind of microbial agent for high-efficiency fermentation bed and preparation method thereof

A microbial agent and composite microbial agent technology, applied in the field of microbial agent for fermentation beds and its preparation, can solve the problems of land occupation, high cost, and large air pollution, and achieve pollution reduction, stable quality, and clear composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: preparation of composite bacterial agent

[0051] 1. Preparation of Bacillus subtilis fermentation product

[0052] Activation of slant strains: Store the slant strains in the refrigerator, aseptically inoculate them into fresh test tube slant medium, and culture at a constant temperature of 37°C overnight to make fresh test tube slant strains. Incline medium: peptone 1%, NaCl 0.5%, yeast extract 0.5%, agar 1.5%-2.0%, the rest is water, pH 7.2-7.4.

[0053] Shake flask seed culture: Take a ring of activated fresh slant strains and inoculate it into the shake flask seed liquid medium by aseptic operation, the filling volume is 100mL / 500mL, the rotation speed is 180-200rpm, and the temperature is 34-37℃ for 22-24h Finally, heat treatment in a water bath at 80°C for 10 minutes. The culture medium of the described shaking flask seeds does not add agar in the slant culture medium.

[0054] Fermentation tank culture: The medium loading in the fermentation tan...

Embodiment 2

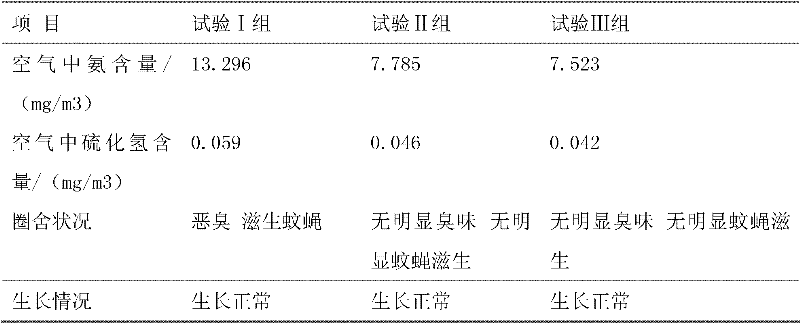

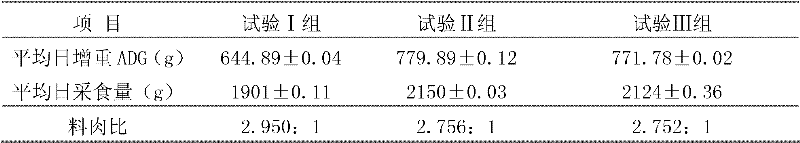

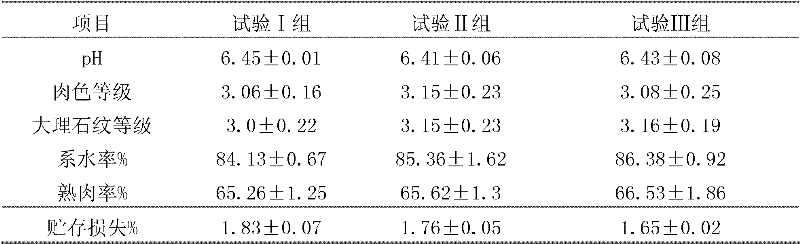

[0068] Embodiment 2: Utilize the composite bacterial agent of the present invention to prepare the pig raising effect of fermentation bed

[0069] 1. Fermentation bed preparation

[0070] The fermented mattress material is composed of sawdust and rice husk in a weight ratio of 1:1, or is composed of sawdust, chaff and crop straw in a weight ratio of 5:3:2. Sawdust, chaff, and crop stalks play the roles of adsorbing bacteria, retaining moisture, loosening and ventilating, and providing C and N sources for functional microorganisms. Before making the fermentation bed, it is best to expose sawdust, rice husk, straw, etc. to the sun for 1 to 2 days, and the pens should be thoroughly disinfected.

[0071] Fermented mattress materials should have no mildew, no corruption, no foul smell or other peculiar smells. The particle size of the material is 2-10mm, the carbon-nitrogen ratio is 40-100:1, the number of fecal coliform bacteria is ≤100cfu / g, the mortality rate of roundworm eggs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com