Method for increasing phytoene dehydrogenase in vitro reaction rate

A technology of phytoene and lycopene, which is applied in the field of bioengineering, can solve problems such as slow reaction rate, and achieve the effects of reducing oxidative loss, improving accuracy, and improving enzymatic reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Ultrasonic mixing method to establish phytoene dehydrogenase in vitro reaction

[0027] (1) Construction of recombinant Escherichia coli expressing phytoene dehydrogenase

[0028] The phytoene dehydrogenase gene (GenBank No. CP000661) of Rhodobacter sphearoides strain preservation number ATCC No. 17025 was amplified by PCR, and connected to Escherichia coli through NdeI and SalI restriction sites A recombinant plasmid was constructed on the expression vector pET-22b (Novagen, Germany), and the recombinant plasmid was transformed into Escherichia coli BL21 (DE3) competent cells to obtain recombinant Escherichia coli expressing phytoene dehydrogenase;

[0029] (2) Preparation of cell disruption solution

[0030] Centrifuge the 200mL recombinant Escherichia coli culture fluid expressing phytoene dehydrogenase prepared in step (1) at 12000rpm for 5 minutes to collect the bacterial cells; resuspend the collected Escherichia coli cells in 10mL, pH7.9 In 100mmol / L...

experiment example 1

[0034] Experimental example 1: The reaction system is not mixed with ultrasonic waves.

[0035] Take 400 μL of the recombinant Escherichia coli disrupted liquid prepared in the example, add the same amount of phytoene acetone solution, glucose, glucose oxidase and catalase as in the example, and make the volume to 500 μL with buffer; mix well Afterwards, 30° C. was protected from light, and the closed shaking reaction was carried out. The reaction conditions, reaction time, reaction termination, and product extraction and detection were the same as in Example 1.

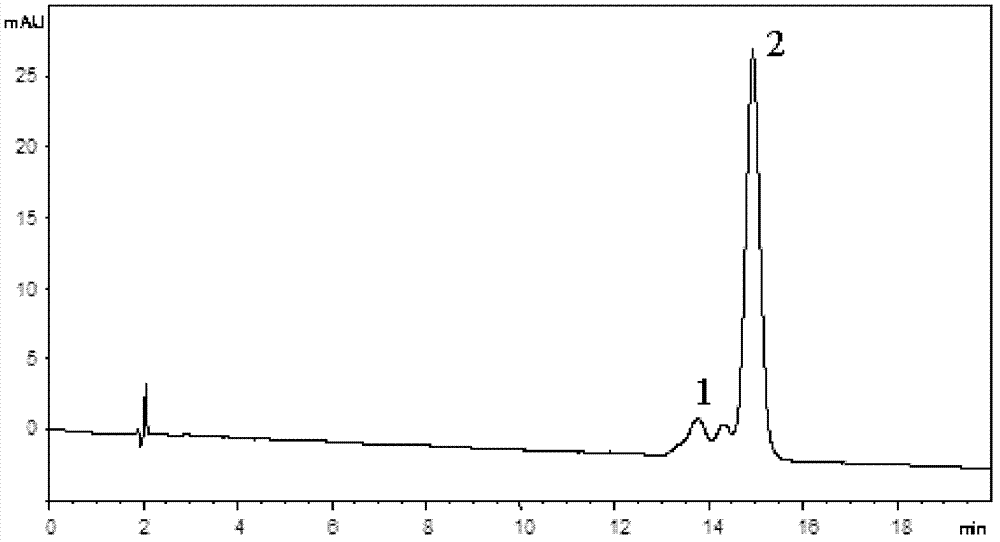

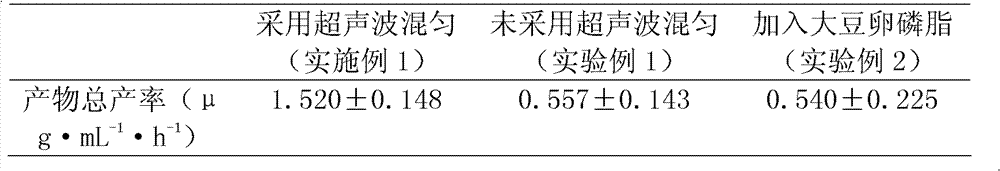

[0036] The above-mentioned reaction system does not need ultrasonic mixing, and the main product in the in vitro reaction system is streptosporine, and a trace amount of lycopene is generated (attached figure 2), the total yield of carotenoid products was 0.557±0.143μg·mL -1 h -1 .

experiment example 2

[0037] Experimental Example 2: Add soybean lecithin emulsion to the control reaction system

[0038] Get 400 μL of recombinant Escherichia coli disrupted solution prepared in the examples, add the same amount of phytoene acetone solution, glucose, glucose oxidase and catalase as in the examples, add 10 μL of 40 mg / mL emulsified soybean lecithin, The volume was adjusted to 500 μL with buffer solution; 30° C. was protected from light and the reaction was shaken in an airtight manner. The reaction conditions, reaction time, reaction termination, and product extraction and detection were the same as in Example 1.

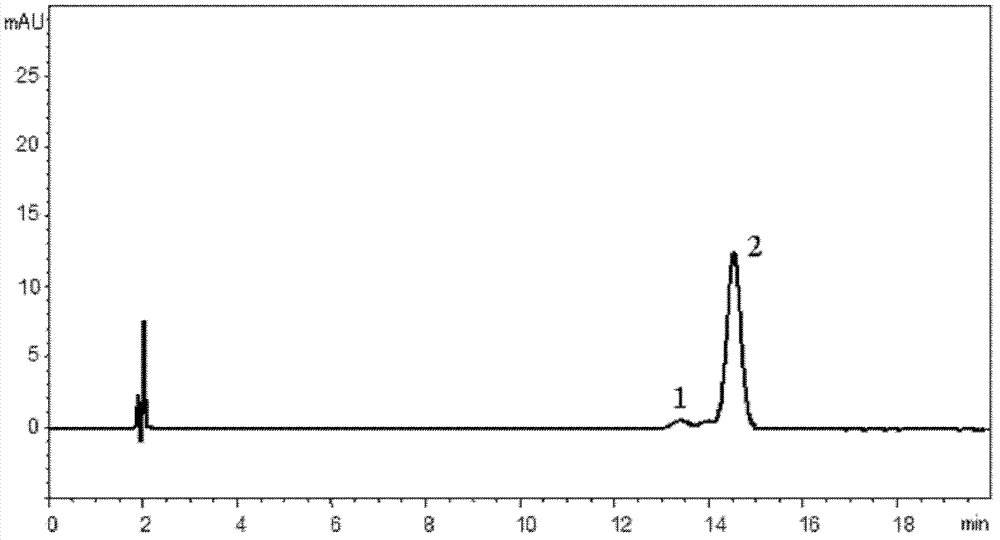

[0039] The above control reaction system was added to the external reaction of soybean lecithin emulsion, and the total yield of the product was 0.540±0.225μg·mL -1 h -1 , similar to Experimental Example 1, soybean lecithin in the crude enzyme solution has no obvious effect on improving the reaction rate.

[0040] The preparation method of the above-mentioned emulsifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com