Electricity enhanced molecular imprinting solid phase micro-extraction method

A molecular imprinting and electrical enhancement technology, applied in separation methods, chemical instruments and methods, material separation, etc., can solve the problems of inability to achieve selective extraction of target compounds, difficulty in analysis and detection of target compounds, etc., and achieve fast extraction speed and service life. The effect of long and large enrichment multiples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

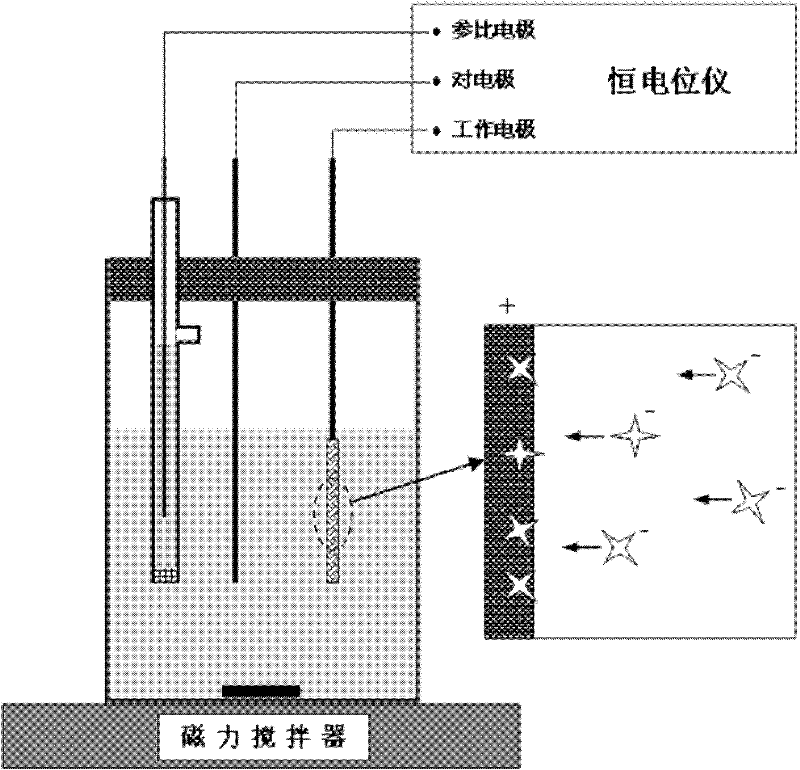

[0023] Prepare 3 mg / mL of N, N-dimethylamide (DMF) carbon nanotube dispersion, insert platinum wire and stainless steel wire with a diameter of 0.6 mm into the above DMF, apply a voltage of 35.6 V, the platinum wire is used as the positive electrode, and keep it for 5 seconds A carbon nanotube layer is obtained on the surface of the platinum wire. A platinum wire with a carbon nanotube layer was inserted into the pre-polymerization solution (0.1mol / L of NaOH, 0.1mol / L of pyrrole and 0.05mol / L ofloxacin) as the positive electrode, and polymerized at a voltage of 0.95V for about 30min, A carbon nanotube-conductive ofloxacin molecularly imprinted polymer composite coating is obtained, that is, a conductive ofloxacin molecularly imprinted microextraction fiber.

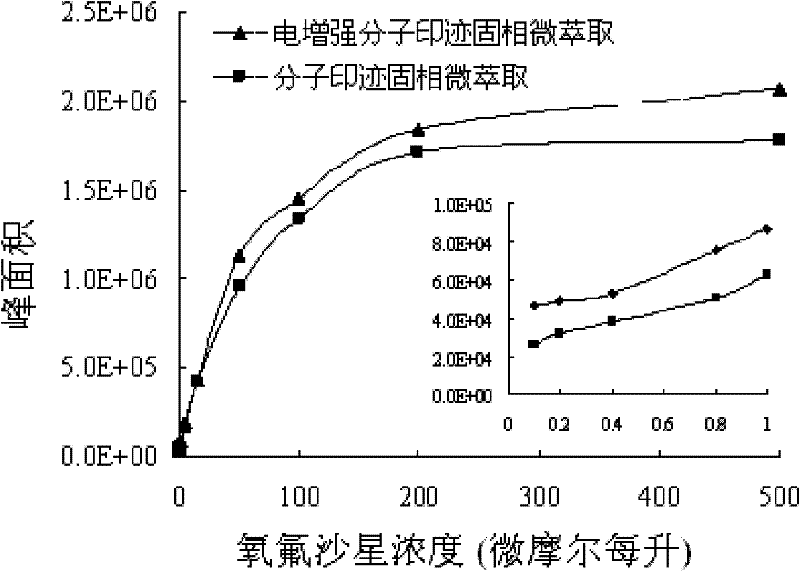

[0024] Prepare 15mL 0.1μmol / L ofloxacin solution in a 20mL vial, use conductive ofloxacin molecularly imprinted micro-extraction fiber working electrode, stainless steel wire as counter electrode, calomel electrode as ref...

Embodiment 2

[0026] Prepare 3 mg / mL of N, N-dimethylamide (DMF) carbon nanotube dispersion, insert titanium wire and stainless steel wire with a diameter of 0.6 mm into the above DMF, apply a voltage of 35.6 V, and use the titanium wire as the positive electrode for 5 seconds. A carbon nanotube layer is obtained on the surface of the titanium wire. Insert a titanium wire with a carbon nanotube layer into a pre-polymerization solution (0.1mol / L NaOH, 0.1mol / L pyrrole and 0.05mol / L tetracycline) as the positive electrode, and polymerize at a voltage of 0.95V for about 30min to obtain carbon nanotubes. Tube-conductive tetracycline molecularly imprinted polymer composite coating, i.e. conductive tetracycline molecularly imprinted microextraction fibers.

[0027] Prepare 15mL of 0.1μmol / L tetracycline solution in a 20mL vial, use conductive tetracycline molecularly imprinted micro-extraction fiber working electrode, stainless steel wire as counter electrode, calomel electrode as reference elect...

Embodiment 3

[0029] Prepare 3 mg / mL of N, N-dimethylamide (DMF) carbon nanotube dispersion, insert platinum wire and stainless steel wire with a diameter of 0.6 mm into the above DMF, apply a voltage of 35.6 V, the platinum wire is used as the positive electrode, and keep it for 5 seconds A carbon nanotube layer is obtained on the surface of the platinum wire. A platinum wire with a carbon nanotube layer was inserted into the pre-polymerization solution (0.1mol / L NaOH, 0.1mol / L pyrrole and 0.05mol / L promethazine) as the positive electrode, and was polymerized at a voltage of 0.95V for about 30min to obtain Carbon nanotube-conductive promethazol molecularly imprinted polymer composite coating, that is, conductive promethazin molecularly imprinted microextraction fiber.

[0030] Prepare 15 mL of 0.1 μmol / L promethazine solution in a 20 mL vial, use the conductive promethazine molecularly imprinted micro-extraction fiber as the working electrode, the stainless steel wire as the counter electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com