Carbonizer for continuously synthesizing calcium carbonate and production method of calcium carbonate

A calcium carbonate and carbonizer technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of wide particle size distribution, large fluctuation range of average particle size, high energy consumption in intermittent production, and easy to achieve. The effect of automated production control, narrow particle size distribution, and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

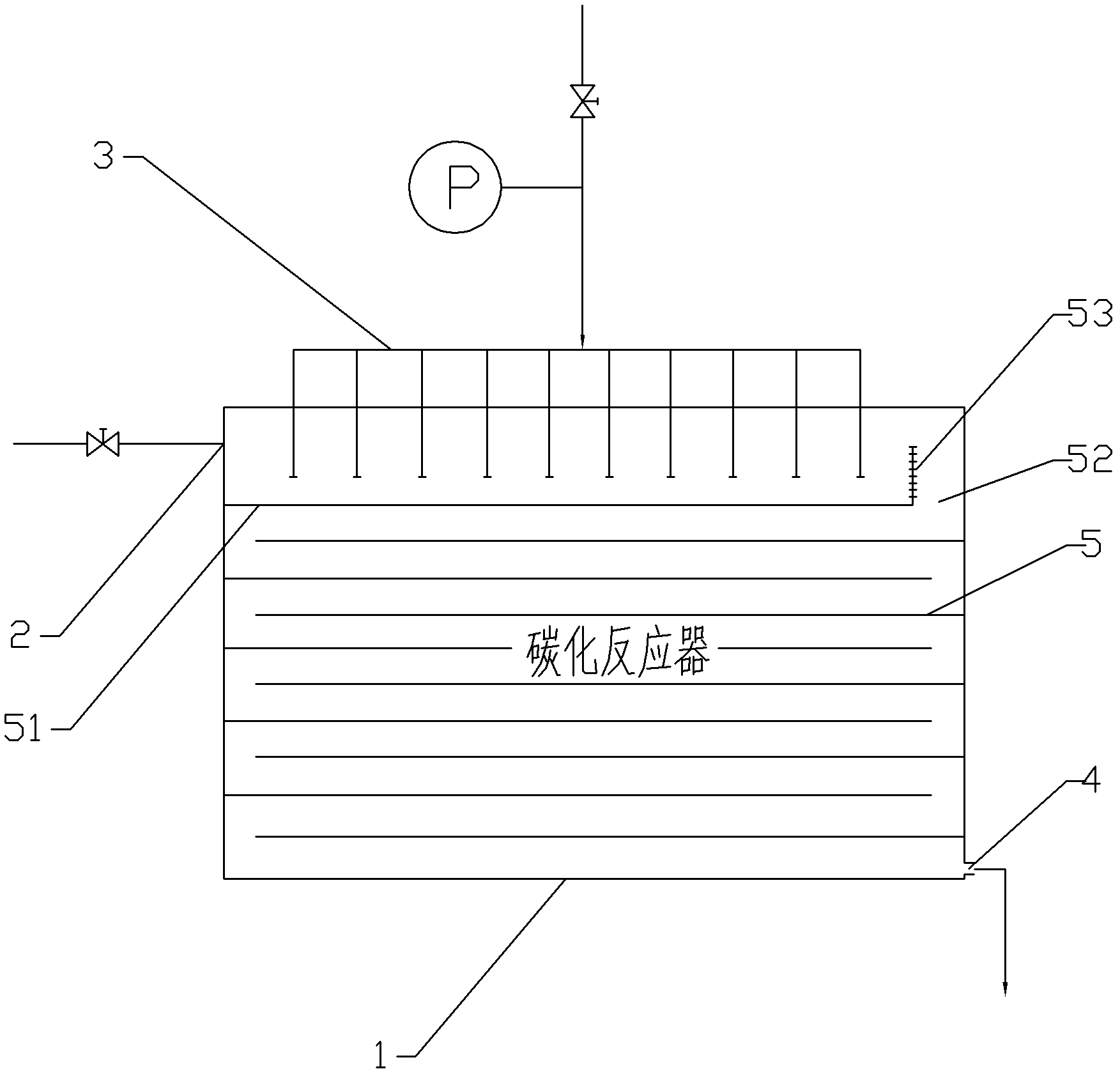

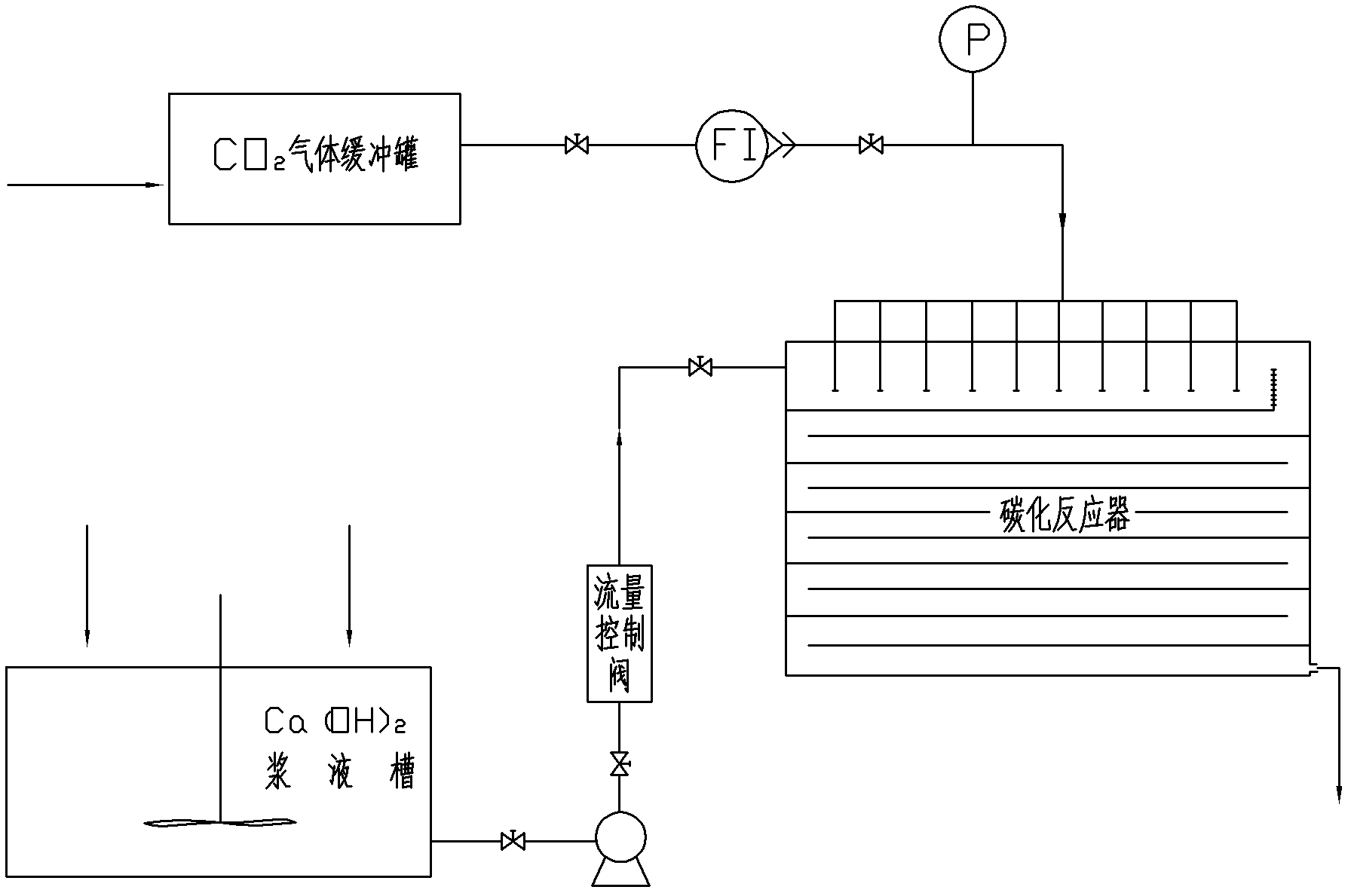

[0033] Such as process flow diagram figure 2 shown, to the CO 2 The buffer tank is fed with purified lime kiln gas with a volume concentration of 28%, namely CO 2 (The same below), to Ca(OH) 2 Ca(OH) 2 Ca(OH) with a concentration of 8% and a temperature of 25°C to 26°C 2 Slurry, start stirring and add 0.2% Ca(OH) by weight 2Calculate citric acid; It is 0.2MPa kiln gas with a gauge pressure of 0.2MPa to feed the carbonization reactor with a flow rate of 18 cubic meters / minute, and then pump Ca(OH) into the carbonization reactor with a flow rate of 20 cubic meters / hour. 2 Slurry, pumped Ca(OH) 2 Serum in as figure 2 The flow of the bubbling carbonized layer shown in the flow process has a carbonization reaction with the kiln gas sent from the kiln gas distribution pipe, flows to the other end and overflows from the top of the sieve plate or sieve plate to the next layer of trays, and continues to flow from the top of the sieve plate. The kiln gas flowing into the tr...

Embodiment 2

[0035] to CO 2 The buffer tank is fed with purified lime kiln gas with a volume concentration of 28%, to Ca(OH) 2 Slurry tank into Ca(OH) 2 Ca(OH) with a concentration of 8% and a temperature of 30°C to 31°C 2 Slurry, start stirring and add 0.5% Ca(OH) by weight 2 Calculating magnesium sulfate; first feed the kiln gas with a gauge pressure of 0.15MPa to the carbonization reactor with a flow rate of 36 cubic meters per minute, and then pump Ca(OH) into the carbonization reactor with a flow rate of 30 cubic meters per hour 2 Slurry, pumped Ca(OH) 2 The slurry flows in the bubbling carbonization layer shown in the figure. During the flow process, it undergoes carbonization reaction with the kiln gas sent from the kiln gas distribution pipe. After flowing to the other end, it overflows from the top of the sieve plate or sieve plate to the next layer of plate, and continues The carbonization reaction occurs with the kiln gas flowing into the tray layer from the top of the s...

Embodiment 3

[0037] To the CO 2 The buffer tank is fed with purified lime kiln gas with a volume concentration of 28%, to Ca(OH) 2 Slurry tank into Ca(OH) 2 Ca(OH) with a concentration of 8% and a temperature of 40°C to 45°C 2 Slurry; first feed the kiln gas with a gauge pressure of 0.12MPa to the carbonization reactor at a flow rate of 52 cubic meters per minute, and then pump Ca(OH) into the carbonization reactor at a flow rate of 40 cubic meters per hour 2 Slurry, pumped Ca(OH) 2 The slurry flows in the bubbling carbonization layer shown in the figure. During the flow process, it undergoes carbonization reaction with the kiln gas sent from the kiln gas distribution pipe. After flowing to the other end, it overflows from the top of the sieve plate or sieve plate to the next layer of plate, and continues The carbonization reaction occurs with the kiln gas flowing into the tray layer from the top of the sieve plate in the same direction, and finally flows out from the bottom of the carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com