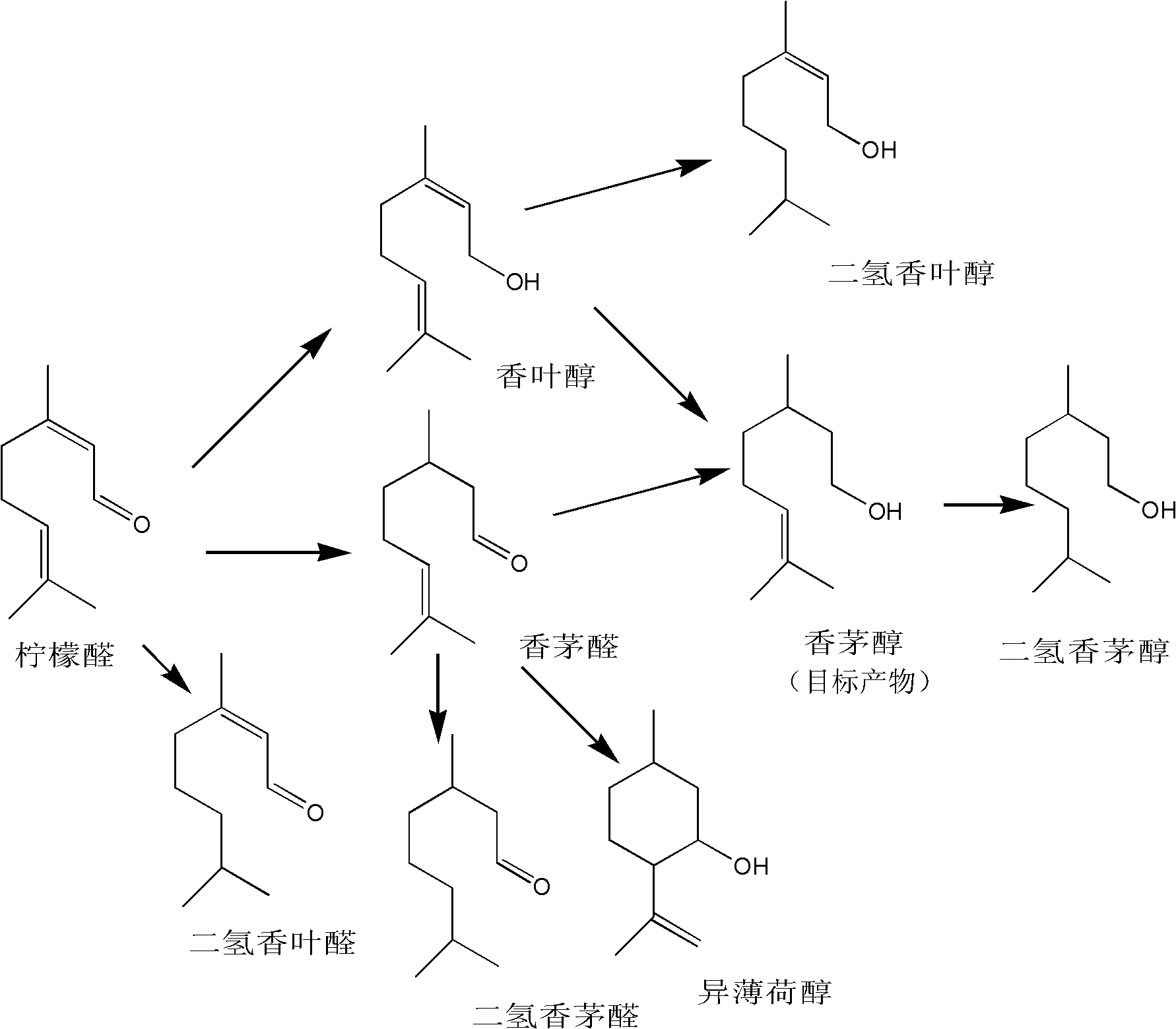

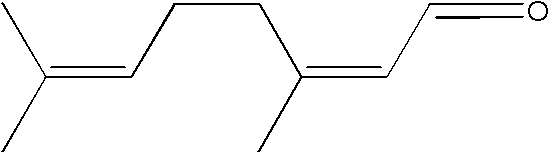

A kind of method that hydrogenation citral prepares citronellol

A technology of citral and citronellol, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as low conversion rate and selectivity, low reaction selectivity, and great environmental hazards of chromium. Achieve the effect of simple separation, simple and flexible operation, and low threshold for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Metal cobalt, nickel, molybdenum, and aluminum are fused at high temperature in proportions of 25%, 30%, 5%, and 40%, respectively, the alloy is cooled to room temperature, crushed, and alloy particles of 400 meshes or more and 50 meshes are screened. Prepare 500 g of sodium hydroxide solution with 20% concentration, boil, slowly add 100 g of alloy particles, continue to boil for 4 hours, and cool. Pour the gray upper layer of turbid liquid, add clean water and wash it repeatedly at room temperature for 3 times. After standing still, the liquid layer is clear and transparent, and the pH value is less than 10. The prepared M2 catalyst is stored under the water seal liquid surface for later use.

[0031] In a 500ml hydrogenation reaction autoclave, 58g of clear water, 2.0g of dipropylamine, 5g of M2 type catalyst with moisture and water, 25g of n-hexane, and 60g of citral (content 96%, the remaining 4% are impurities) were added successively. Seal the autoclave, replace wit...

Embodiment 2

[0034] Metal cobalt, nickel, molybdenum, and aluminum are fused at high temperature in proportions of 0.8%, 40%, 7%, and 52.2% respectively, the alloy is cooled to room temperature, crushed, and alloy particles of 400 meshes or more and 50 meshes are screened. Prepare 500 g of sodium hydroxide solution with 20% concentration, boil, slowly add 100 g of alloy particles, continue to boil for 4 hours, and cool. Pour the gray upper layer of turbid liquid, add clean water and wash it repeatedly at room temperature for 3 times. After standing still, the liquid layer is clear and transparent, and the pH value is less than 10. The prepared catalyst is stored under the water seal liquid surface for later use.

[0035] In a 500ml hydrogenation reaction autoclave, 14g of clear water, 0.08g of n-heptylamine, 15g of M2 type catalyst moistened with water, 70g of benzene, and 50g of citral (content 96%, the remaining 4% are impurities) are added successively. Seal the autoclave, replace with ni...

Embodiment 3

[0038] Metal cobalt, nickel, molybdenum, and aluminum are fused at high temperature in proportions of 20%, 40%, 3.5%, and 36.5% respectively, the alloy is cooled to room temperature, crushed, and alloy particles of 400 meshes or more and 50 meshes are screened. Prepare 500 g of sodium hydroxide solution with 20% concentration, boil, slowly add 100 g of alloy particles, continue to boil for 4 hours, and cool. Pour the gray upper layer of turbid liquid, add clean water and wash it repeatedly at room temperature for 3 times. After standing still, the liquid layer is clear and transparent, and the pH value is less than 10. The prepared catalyst is stored under the water seal liquid surface for later use.

[0039] In a 500ml hydrogenation reaction autoclave, 18g of clear water, 0.9g of diisohexylamine, 20g of M2 type catalyst moistened with water, 75g of petroleum ether, and 47g of citral (content 96%, the remaining 4% are impurities) were added successively. Seal the autoclave, repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com