Method for producing ethanol or acetone and butanol by taking lignocellulose as raw material

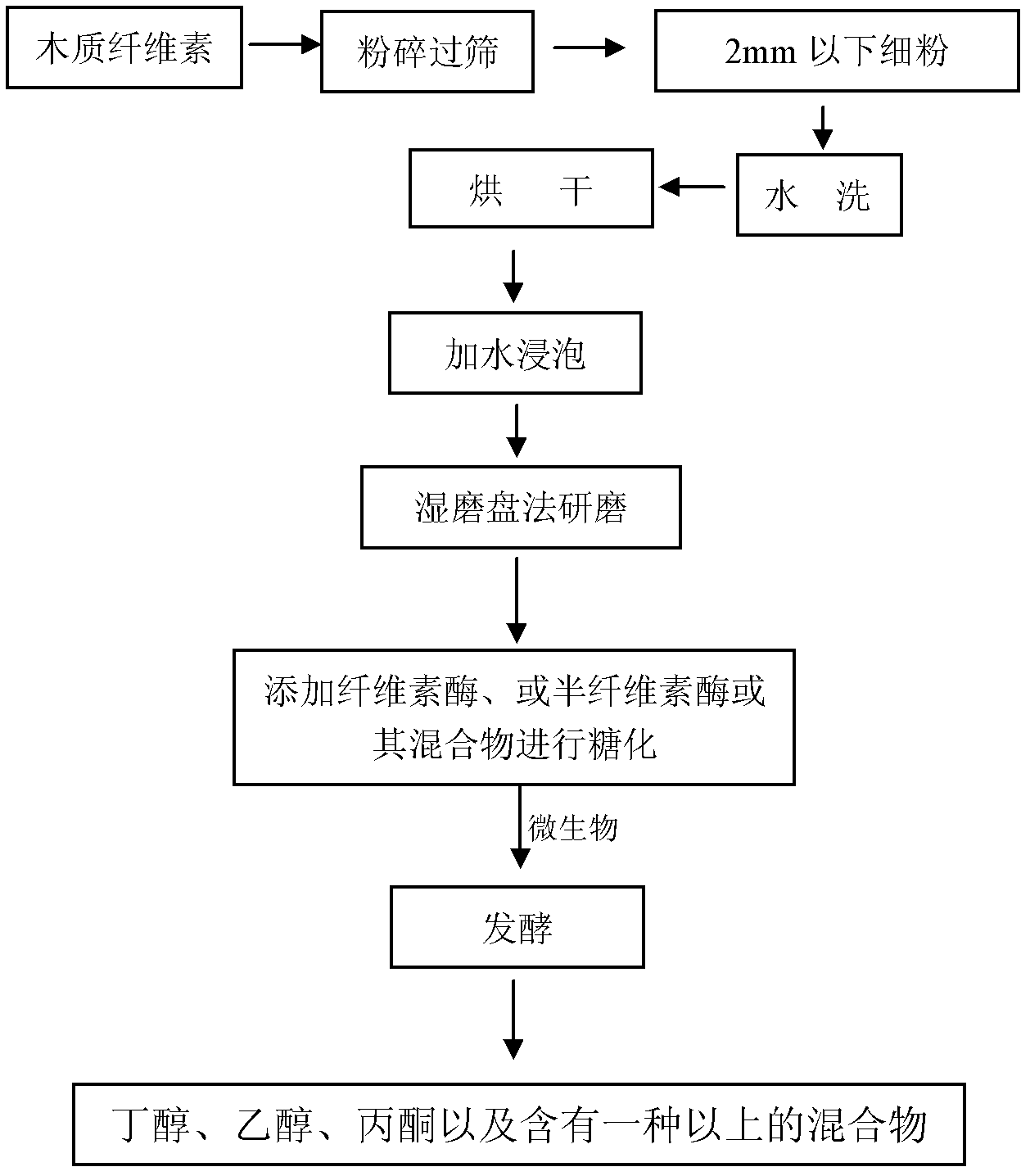

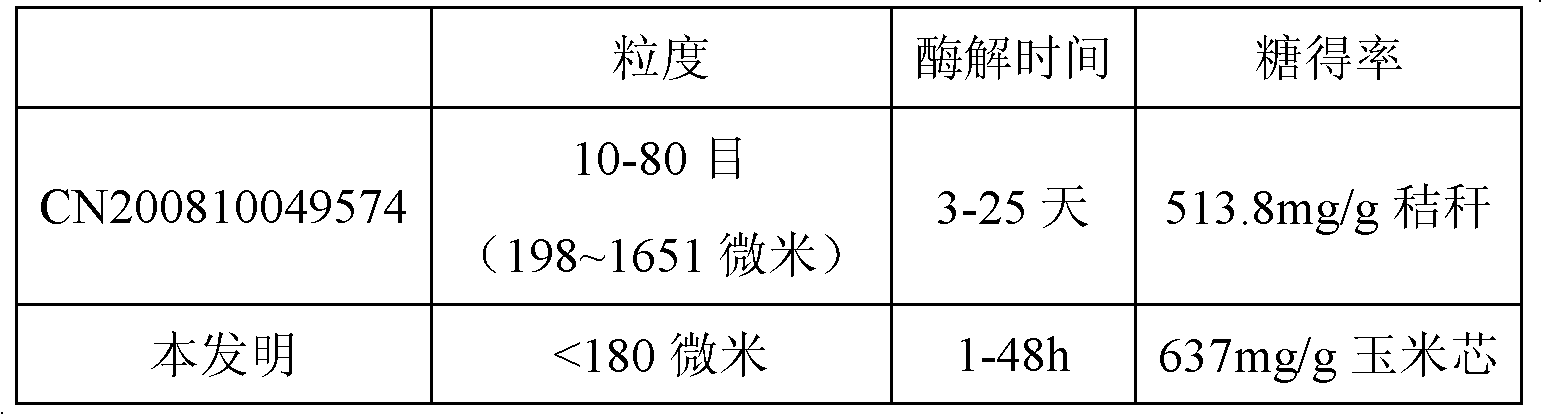

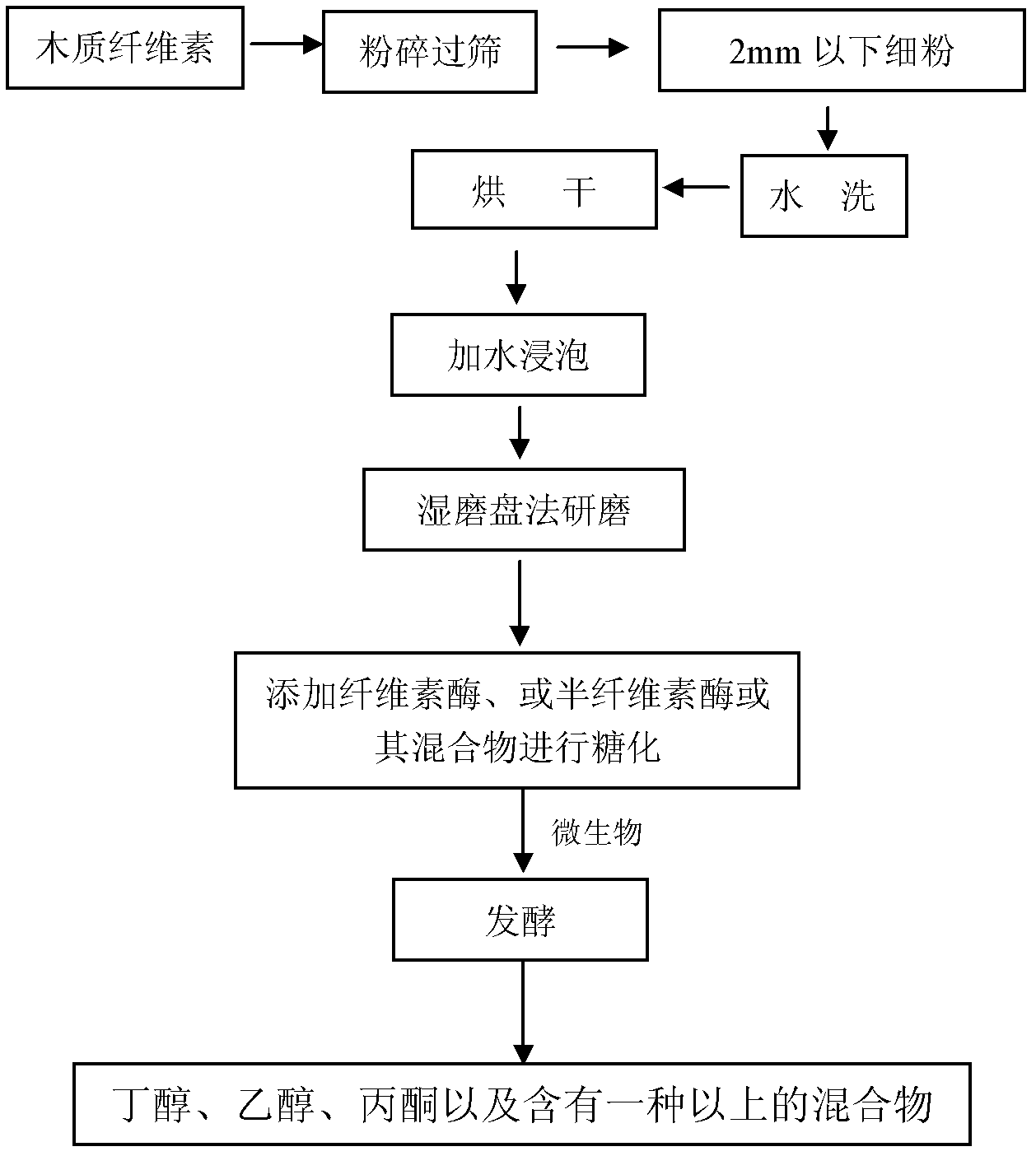

A technology of lignocellulose and acetone butanol, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of long enzymatic hydrolysis time, high investment cost, long production cycle, etc., and achieve high hydrolysis efficiency , the effect of small energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The corncob was pulverized into 1mm powder with a pulverizer, then rinsed with water, and then dried at 60°C overnight. Mix 500g of corncob flour below 1-2mm with 10L of water, and place it for anaerobic fermentation at 10°C for 1 day. When the pH drops to 4.5, adjust the wet disc grinder - Japan MKZA10 ultra-fine particle melter (Yoshiko). Sangyo Co., Ltd., Japan) The gap between the two upper and lower disc grinding discs should be 1 micron to a suitable gap. Mix the material and liquid refrigerated at 4 °C, add it to the ultra-fine melter, and grind for 10 to 15 circles, and its particle size is 2 μm. In between, the soluble sugar content was 0.385 g / g corncob, of which the glucose content was about 65% and the xylose content was about 20%. The complex cellulase was added to the pretreatment solution in an amount of 5%. The hydrolysis conditions were as follows: 10.0 mL pH 4.5, under the condition of 50 °C, 200 rpm rotary shaking for 48 h. The content of soluble su...

Embodiment 2

[0038] The corncob was pulverized into a 2mm powder with a pulverizer. Mix 500g of corncob flour below 2mm with 5L of water, put it at 4°C for 1 day, and place it at 4°C for 2 days for anaerobic fermentation. When the pH drops to 5.0, adjust the wet disc grinder - Japan MKZA10 ultra-fine melting Crusher (Mashiko Sangyo Co., Ltd., Japan) The gap between the two upper and lower disc grinding discs is 2 microns to a suitable gap, and after grinding for 15 circles, add 10FPU / g Acremonium complex cellulase and 0.4% β- Xylosidase; pre-hydrolyze at 50°C for 1h after mixing, add 0.1% yeast powder, keep the temperature at 37°C after mixing, insert acetone-butanol-producing microorganism Clostridium beijerinckii ATCC55025 at an inoculum of 5%, and ferment 72h, the butanol content was 7.8g / L, and the acetone content was 4.1g / L.

Embodiment 3

[0040] Pulverize the bran into 1mm powder with a pulverizer, mix 500g of the material liquid with 5L of water, and place it for anaerobic fermentation at 4°C for 2 days. When the pH drops to 4.8, adjust the wet disc grinder - Japan MKZA10 Ultra The gap between the two upper and lower disc grinding discs of the microparticle thawing machine (Mashiko Sangyo Co., Ltd., Japan) is to a suitable gap of 10 microns, and the anaerobic material and liquid at 4 °C are mixed. , the soluble sugar content is 0.151g / g bran. The pretreatment solution was added with 6.4 FPU / g Acremonella cellulase (complex enzyme with endonuclease and exonuclease) and 40 μL / g β-xylosidase according to the addition amount of 5% for hydrolysis for 48h. The soluble sugar content was 0.531 g / g bran. The above-mentioned bran is pretreated and enzymatically hydrolyzed into the mixed liquid, adding 0.1% yeast powder, pH 5.5 to 7.0, and inserting acetone butanol to produce microorganism Clostridiumbeijerinckii ATCC55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com