Method for preparing WC-Co nano composite powder by in situ reduction and carbonization

A nano-composite and in-situ technology, applied in the field of cemented carbide powder preparation, can solve the problems of difficult control of the process, expensive equipment, long reaction time, etc., and achieve the effects of improving efficiency, reducing energy consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The first step, according to the WC-15wt%Co measurement ratio, weighed 11.57g (46%) of ammonium tungstate, 7.3g (29%) of cobalt nitrate, and 6.26g (25%) of glucose, respectively dissolved in deionized water, and prepared into a clear mixed solution 75ml;

[0042] In the second step, put the mixed solution obtained in the first step in a PTFE-lined 100ml hydrothermal reaction kettle, seal it, put it in an oven, heat it to 150°C±5°C, keep it warm for 6h, and then cool it with the furnace to room temperature, and then the reactants were filtered, washed, and dried to obtain the precursor powder;

[0043] The third step is to put the precursor powder obtained in the third step into the crucible, heat it in a vacuum tube furnace, and under the condition of vacuum pressure ≤ 80Pa, heat it to 1000°C ± 5°C at a heating rate of 8°C / min, and keep it for 2h , that is, WC-Co nanocomposite powder with an average particle size of about 60nm.

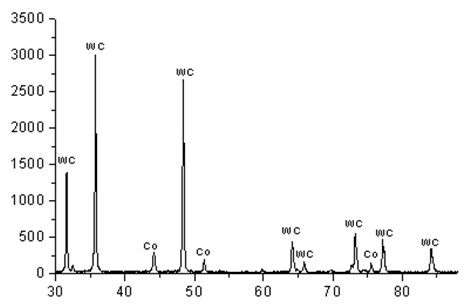

[0044] Its XRD diffraction pattern is ...

Embodiment 2

[0046] In the first step, according to the WC-8wt%Co measurement ratio, weigh 11.85g (55.4%) of ammonium metatungstate, 3.2g (15%) of cobalt chloride, and 6.33g (29.6%) of glucose, and dissolve them in deionized water respectively. Prepare 75ml of clear mixed solution;

[0047] In the second step, put the mixed solution obtained in the first step into a 100ml hydrothermal reaction kettle lined with polytetrafluoroethylene, seal it, put it in an oven, heat it to 150°C±5°C, keep it warm for 10h, and then cool it down to At room temperature, the reactant is filtered, washed, and dried to obtain the precursor powder;

[0048] In the third step, put the precursor powder obtained in the second step into a crucible, heat it in a protective atmosphere furnace, and heat it to 1000°C ± 5°C at a heating rate of 8°C / min under a high-purity argon atmosphere, and keep it warm. After 3 hours, the WC-Co nanocomposite powder is obtained, with an average particle size of about 60nm.

Embodiment 3

[0050] In the first step, according to the WC-12 wt% Co measurement ratio, weigh 11.34g (49.7%) of ammonium metatungstate, 5.84g (25.6%) of cobalt nitrate, and 5.65g (24.7%) of soluble starch (AR). In deionized water, prepare 75ml of clear mixed solution;

[0051] In the second step, put the mixed solution obtained in the first step into a 100ml hydrothermal reaction kettle lined with polytetrafluoroethylene, seal it, put it in an oven, heat it to 150°C±5°C, keep it warm for 4h, and then cool it down to At room temperature, the reactant is filtered, washed, and dried to obtain the precursor powder;

[0052] In the third step, put the precursor powder obtained in the second step into the crucible, heat it in a vacuum tube furnace, and under the condition of vacuum pressure ≤ 80Pa, heat it to 1100°C ± 5°C at a heating rate of 8°C / min, and keep it for 1h , that is, WC-Co nanocomposite powder with an average particle size of about 60nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com