High-hardness micrometer grinding fluid and preparation method thereof

A technology of abrasive liquid and high hardness, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as uneven particle size, difficult dispersion of abrasive particles, and imbalance of pH value of abrasive liquid, etc., to achieve a complete wafer structure , good adaptability and balanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

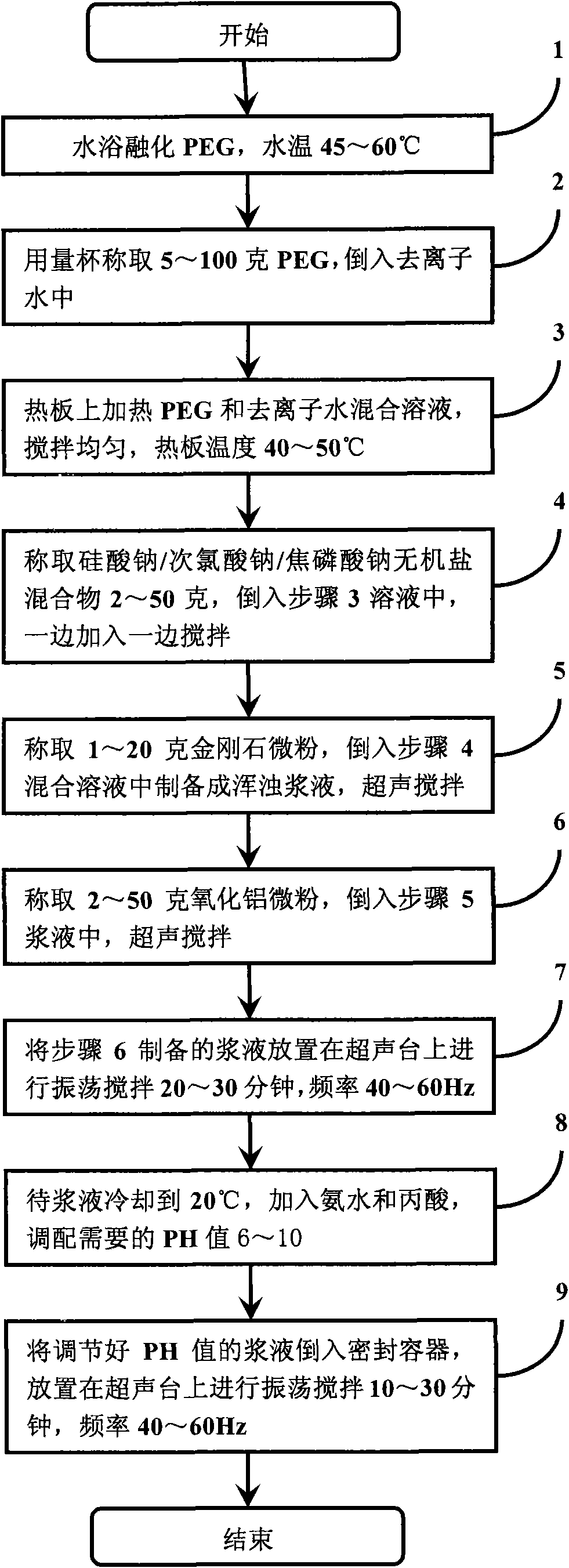

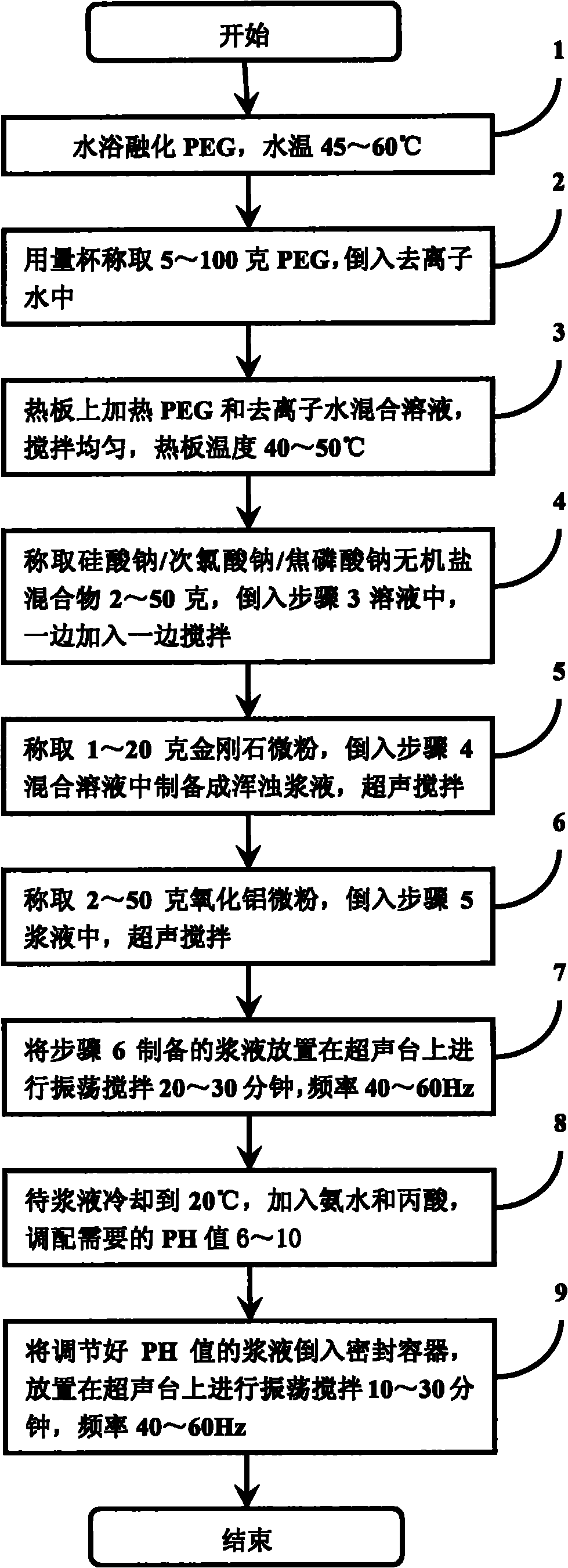

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0032] In the early stage of grinding, if it is necessary to reduce the thickness of the wafer on a large scale, it is most suitable to use an iron disc with a hard texture and a small elastic coefficient as the grinding disc.

[0033] The lapping liquid provided by the present invention for thinning and grinding high-hardness GaN epitaxial substrates adopts single crystal artificial diamond (CBN, cubic boron nitride) micropowder and alumina micropowder, the particle diameter of which is 25-1 μm, and adopts inorganic Salt mixture sodium silicate / sodium hypochlorite / sodium pyrophosphate as dispersant, organic PEG200 as lubricant, ammonia water and propionic acid as pH regulator, deionized water (DI) as solvent. The specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com