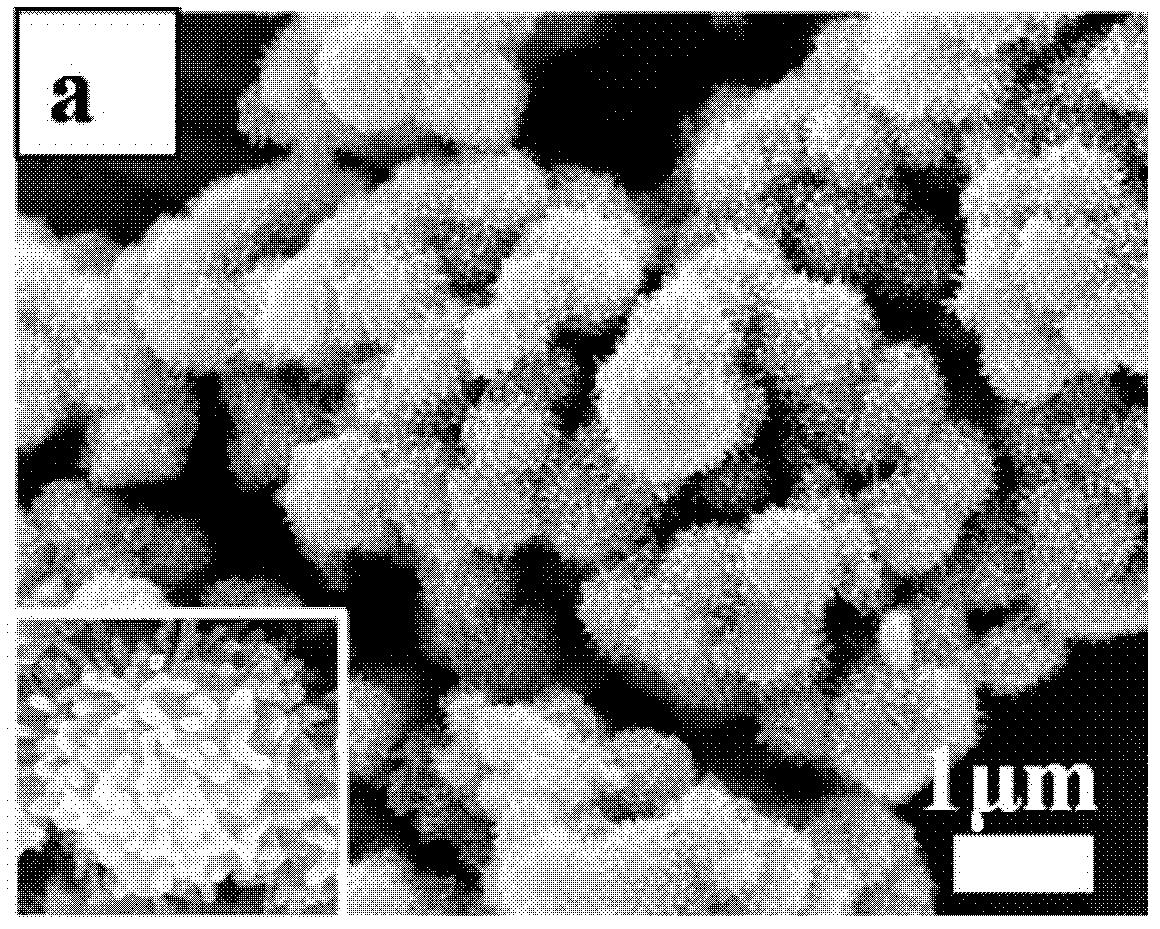

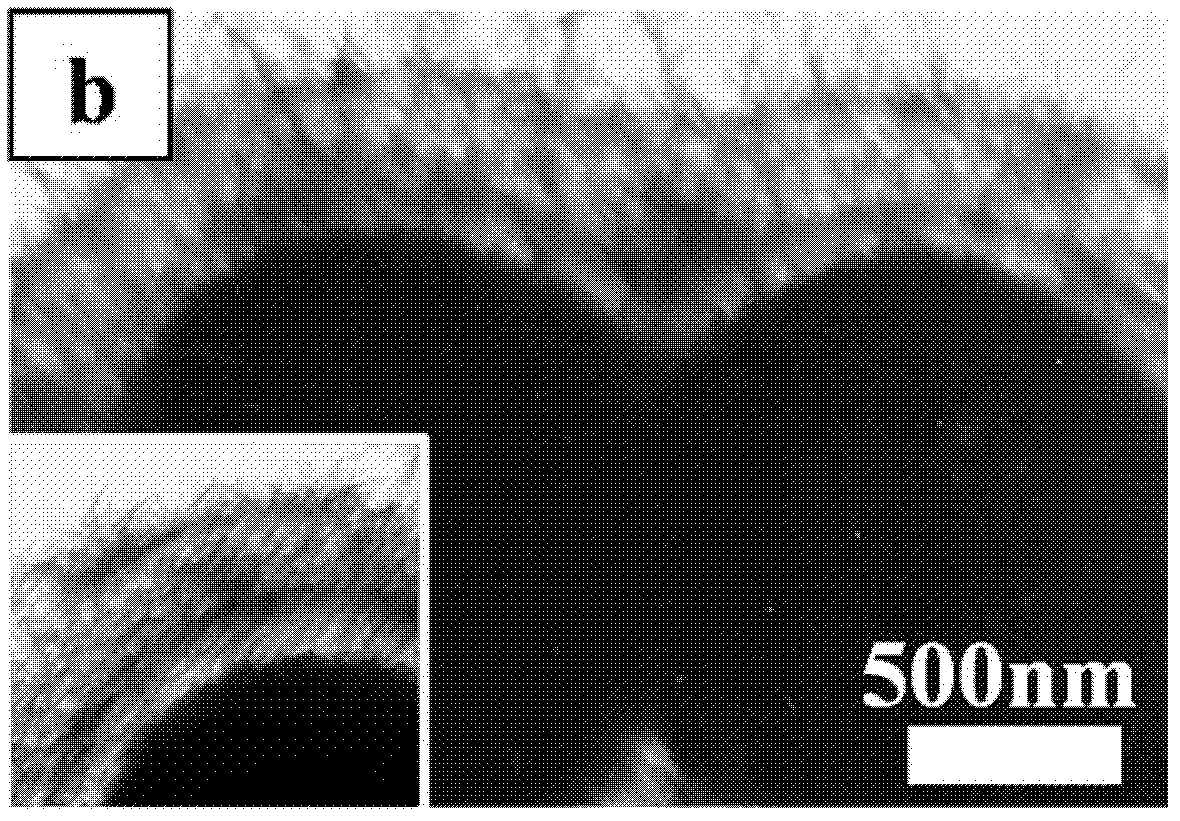

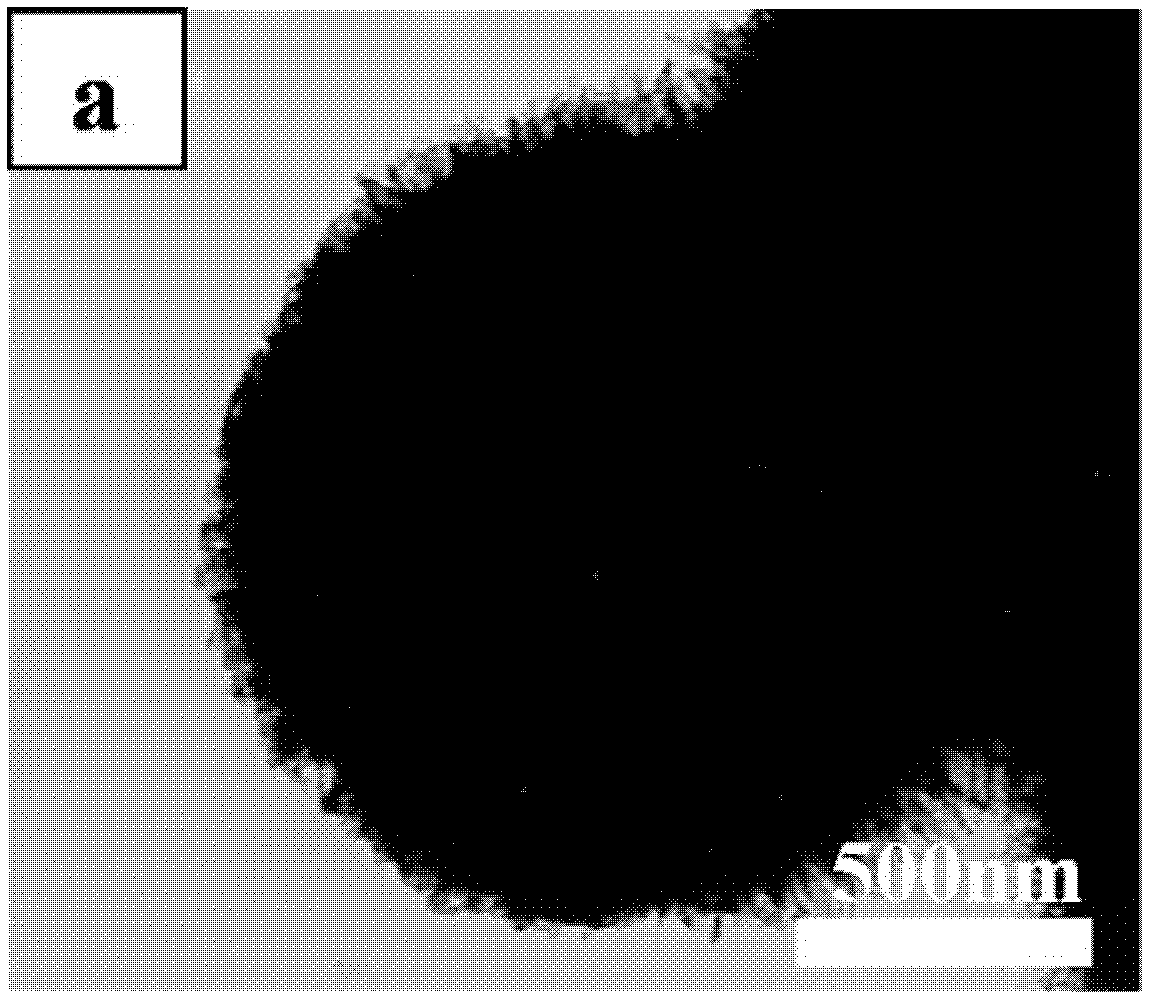

Preparation method of urchin-like titanium dioxide magnetic microspheres having double-layer cavity structures

A technology of titanium dioxide and magnetic microspheres, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems such as no reports on titanium dioxide magnetic microspheres, and achieve simple The effect of rapid separation and recovery, large specific surface area and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Step 1: Preparation of monodisperse ferric ferric oxide magnetic microspheres: Add ferric chloride to ethylene glycol at 40°C, add anhydrous sodium acetate under stirring, stir vigorously for 0.5h, and then mix Transfer the solution to an airtight container, control the temperature at 180°C for 10 hours, centrifuge, wash with alcohol, wash with water, and dry to obtain magnetic ferric oxide microspheres with a diameter of 300-700nm for use; wherein, the mass ratio of each material For: ferric chloride: ethylene glycol: anhydrous sodium acetate = 1:41:3;

[0026] Step 2: Ultrasonic disperse the magnetic ferric oxide microspheres prepared in the above steps in 50mL, 0.1 molL -1 In hydrochloric acid, magnetically separate, then add ethanol, deionized water and ammonia water with a volume concentration of 25%-28%, stir mechanically at room temperature, then slowly add a mixed solution prepared by ethyl orthosilicate and ethanol dropwise, and react for 6h , through centrifu...

example 2

[0032] Step 1: Preparation of monodisperse ferric ferric oxide magnetic microspheres: Add ferric chloride to ethylene glycol at 60°C, add anhydrous sodium acetate under stirring conditions, stir vigorously for 1.5h, and then mix Transfer the solution to an airtight container, control the temperature at 100°C for 18 hours, centrifuge, wash with alcohol, wash with water, and dry to obtain magnetic ferric oxide microspheres with a diameter of 300-700nm for future use; wherein, the mass ratio of each material For: ferric chloride: ethylene glycol: anhydrous sodium acetate = 1:20:2;

[0033] Step 2: Ultrasonic disperse the magnetic ferric oxide microspheres prepared in the above steps in 50mL, 0.1 molL -1In hydrochloric acid, magnetically separate, then add ethanol, deionized water and ammonia water with a volume concentration of 25%-28%, stir mechanically at room temperature, then slowly add the mixed solution prepared by ethyl orthosilicate and ethanol dropwise, and react for 5h ...

example 3

[0038] Step 1: Preparation of monodisperse ferric ferric oxide magnetic microspheres: Add ferric chloride to ethylene glycol at 70°C, add anhydrous sodium acetate under stirring conditions, stir vigorously for 2.5 hours, and then mix Transfer the solution to an airtight container, control the temperature at 200°C for 12 hours, centrifuge, wash with alcohol, wash with water, and dry to obtain magnetic ferric oxide microspheres with a diameter of 300-700nm for use; wherein, the mass ratio of each material For: ferric chloride: ethylene glycol: anhydrous sodium acetate = 1:60:5;

[0039] Step 2: Ultrasonic disperse the magnetic ferric oxide microspheres prepared in the above steps in 50mL, 0.1 molL -1 In hydrochloric acid, magnetically separate, then add ethanol, deionized water and ammonia water with a volume concentration of 25%-28%, stir mechanically at room temperature, then slowly add a mixed solution prepared by ethyl orthosilicate and ethanol dropwise, and react for 6h , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com