Method for improving interface caking property of dye sensitized solar cell substrate

A solar cell and dye sensitization technology, applied in the field of solar cell utilization, can solve the problem of poor interface adhesion between connecting nano-thin film photoelectrode and conductive substrate, lower distribution quality of upper semiconductor nanocrystalline thin film, lower electron transport performance and collection efficiency and other problems, to achieve the effect of maintaining good network structure morphology, stable performance of photoelectrode materials, and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

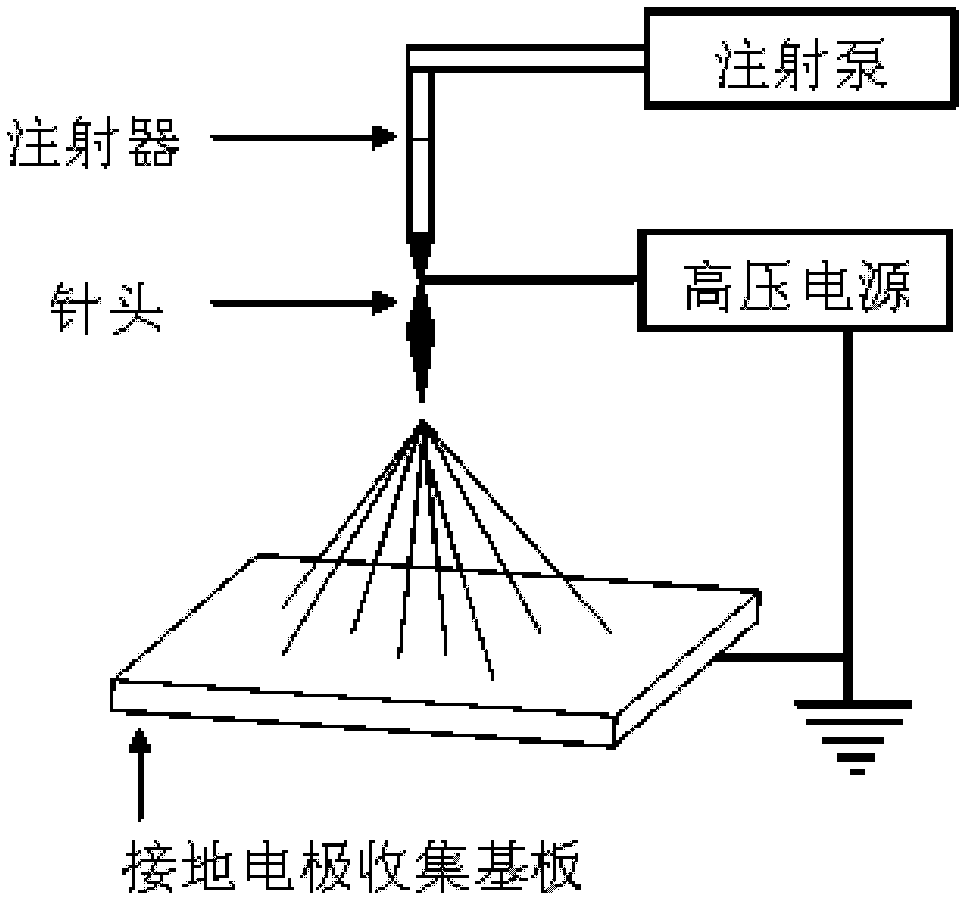

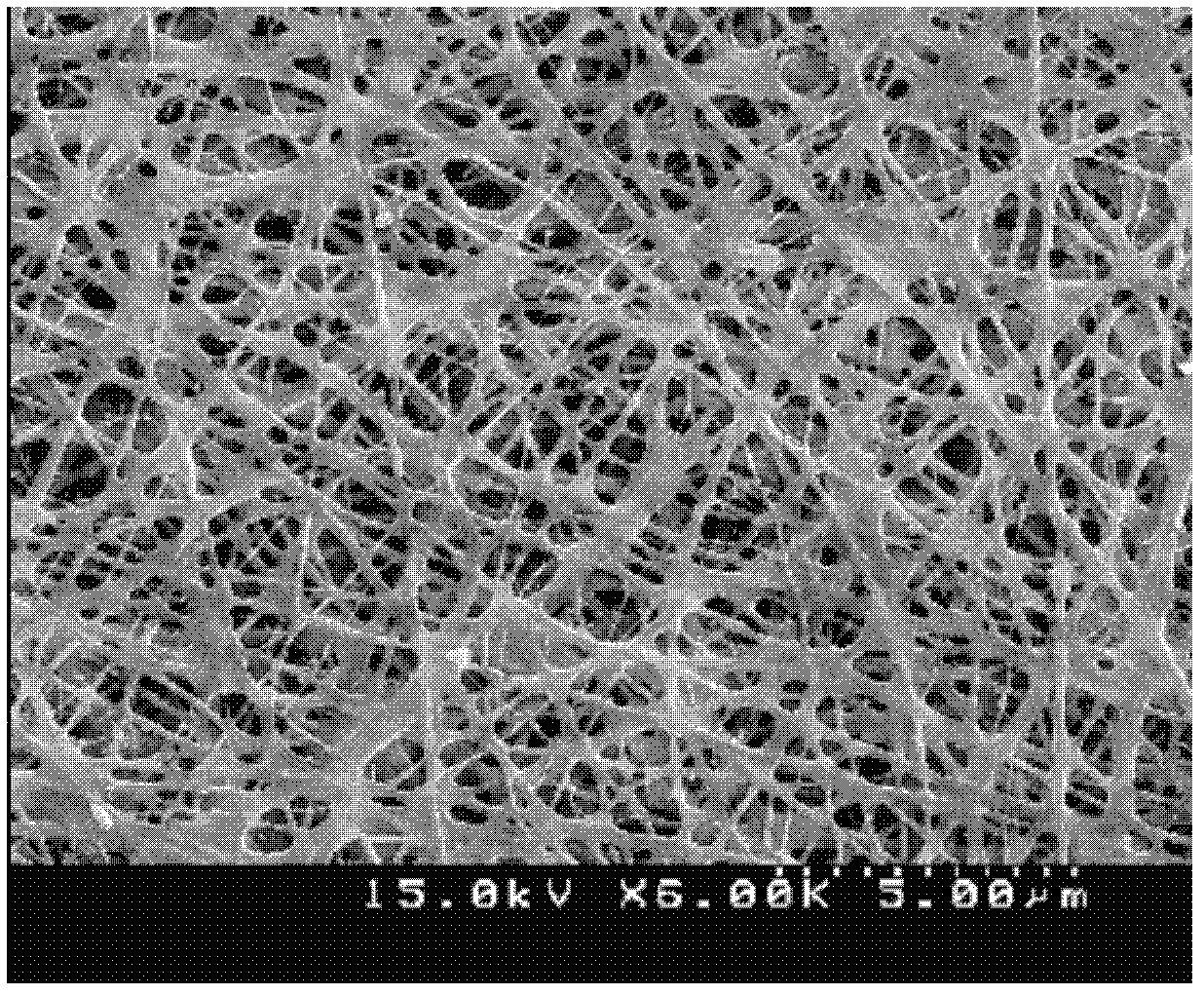

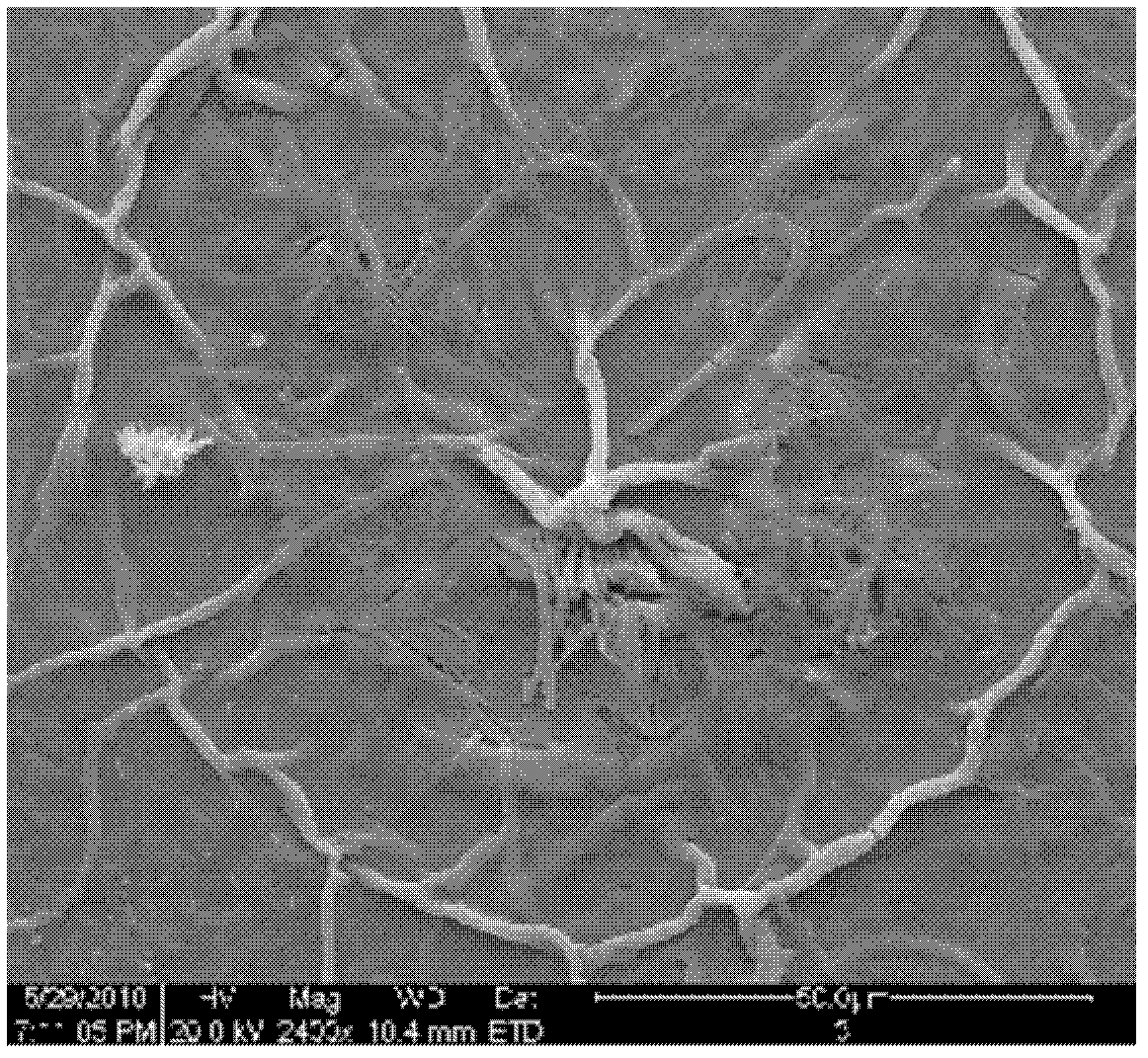

Method used

Image

Examples

preparation example Construction

[0060] 3) Preparation of ZnO precursor polymer gel:

[0061] The hydrated salt of zinc (Zn(CH 3 COO) 2 2H 2 O, ZnSO 4 ·7H 2 O or Zn(NO 3 ) 2 ·6H 2 One in O), polymer (one in PVAc, PVA or PVP), solvent (one or two in DMF, deionized water or ethanol) and catalyst (acetic acid, add or not add) press Put the ratio listed in the table into the beaker, or further add dopant (Al(NO 3 ) 3 9H 2 O, Al 2 (SO 4 ) 3 ·xH 2 O, AlCl 3 ·6H 2 One of O, added or not), heated to 60°C; at a speed of 240-400r / min, magnetically stirred for 6hrs to obtain a uniform and transparent ZnO precursor polymer gel. The ZnO precursor polymer gel is formulated according to the raw materials in the following table 1 parts by weight:

[0062] Table 1 Raw material composition weight parts of ZnO precursor polymer gel (unit: gram)

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com