Dispersion of rutile titanium oxide particles, method for producing same and use of same

A rutile type, titanium oxide technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as inability to improve crystallinity, achieve effective UV shielding, excellent dispersion stability, and high refraction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

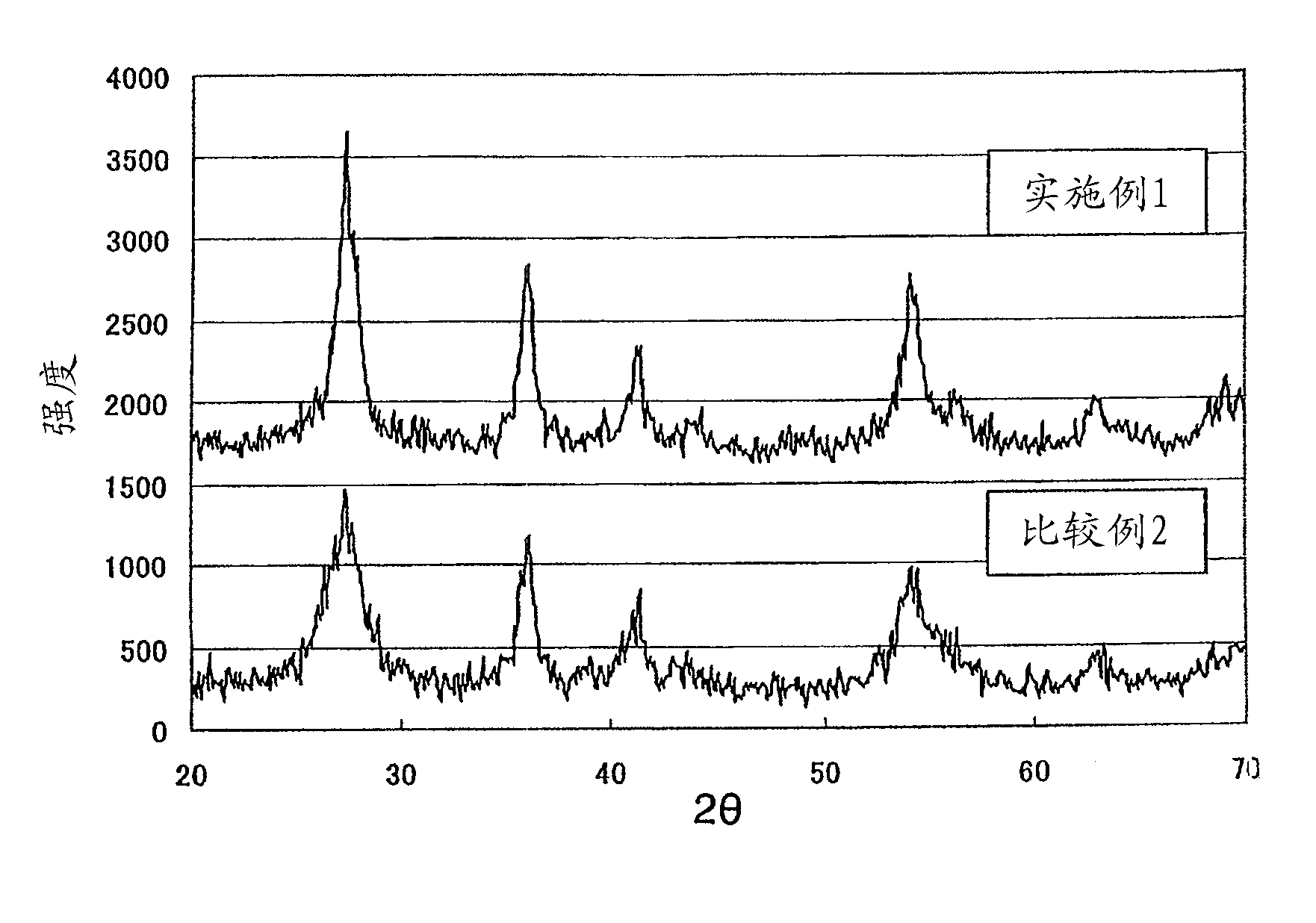

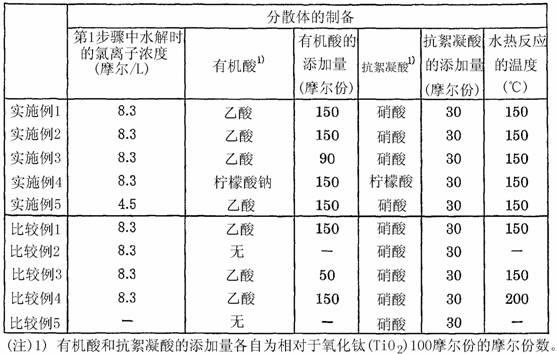

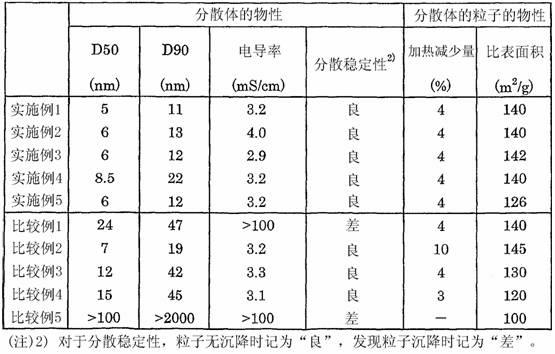

Embodiment 1

[0068] Step 1

[0069] The aqueous solution of titanium tetrachloride was diluted with water and adjusted so that it was 200 g / L as titanium oxide and the chloride ion concentration was 8.3 mol / L. 1 L of the titanium tetrachloride aqueous solution was charged into a separable flask equipped with a reflux device, heated at the boiling point (110° C.) for 2 hours, and hydrolyzed to obtain a slurry containing precipitated rutile-type titanium oxide particles.

[0070] Step 2

[0071]The slurry was filtered using a glass fiber filter paper with a collection diameter of 300 nm to remove unreacted titanium tetrachloride and dissolved components. The rutile-type titanium oxide particles thus obtained were made into a slurry in water, and an aqueous sodium hydroxide solution was added to the obtained slurry until the slurry had a pH of 7.0, and then filtered using a glass fiber filter paper with a collection diameter of 300 nm. At this time, the rutile-type titanium oxide was slurri...

Embodiment 2

[0082] In the fifth step of Example 1, a dispersion of rutile-type titanium oxide particles was obtained in the same manner as in Example 1 except that hydrochloric acid was used instead of nitric acid for deflocculation.

Embodiment 3

[0084] In the third step of Example 1, a dispersion of rutile-type titanium oxide particles was obtained in the same manner as in Example 1 except that 90 mol parts of acetic acid was added to 100 mol parts of titanium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com