Preparation of long-acting chitosan/apatite/rifampicin composite material by biomimetic mineralization method

A biomimetic mineralization and composite material technology, applied in medical science, prosthesis, etc., can solve the problems of unguaranteed drug efficacy and safety, short drug release time, etc., and achieve the effect of maintaining drug activity and increasing sustained release time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

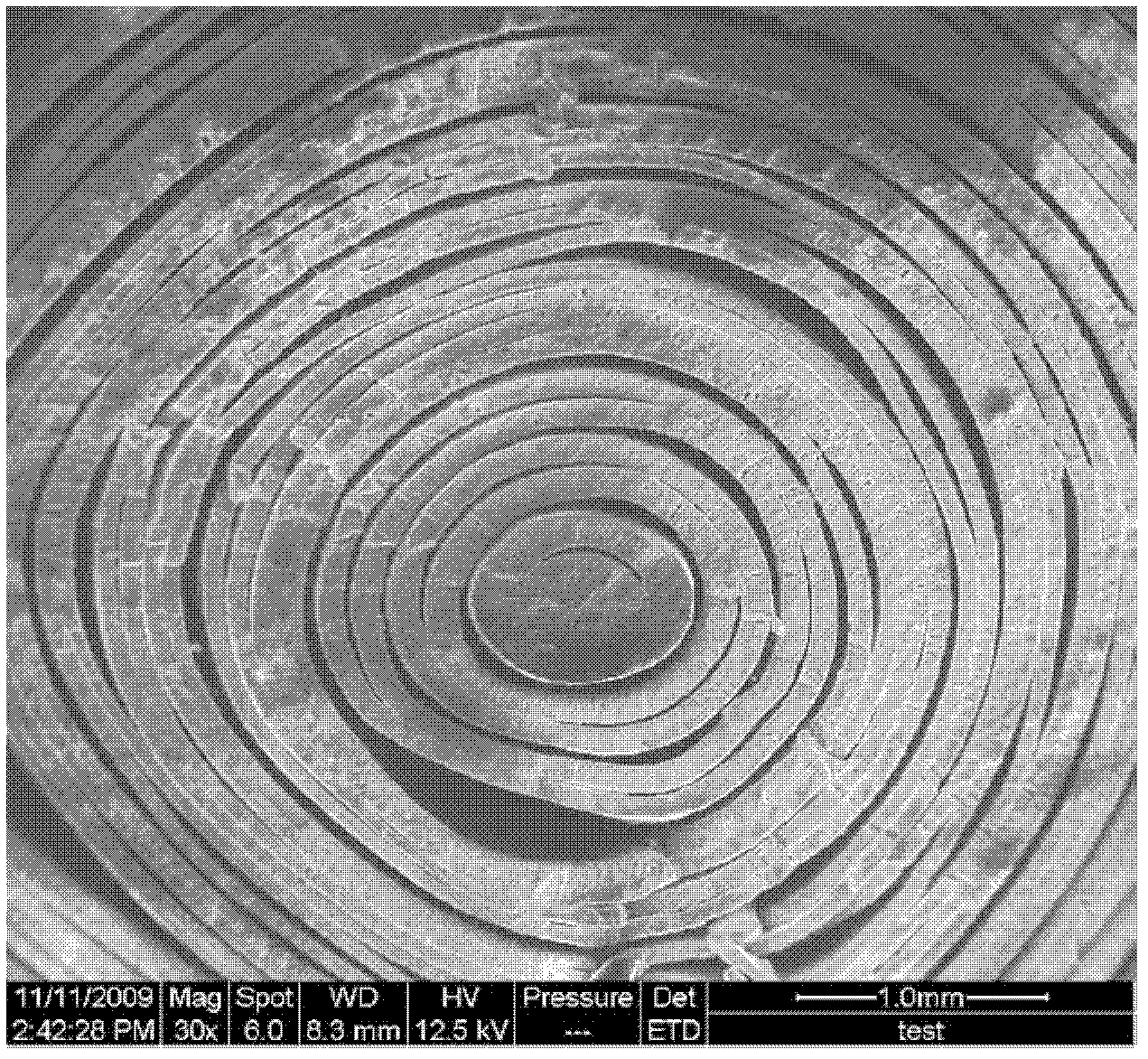

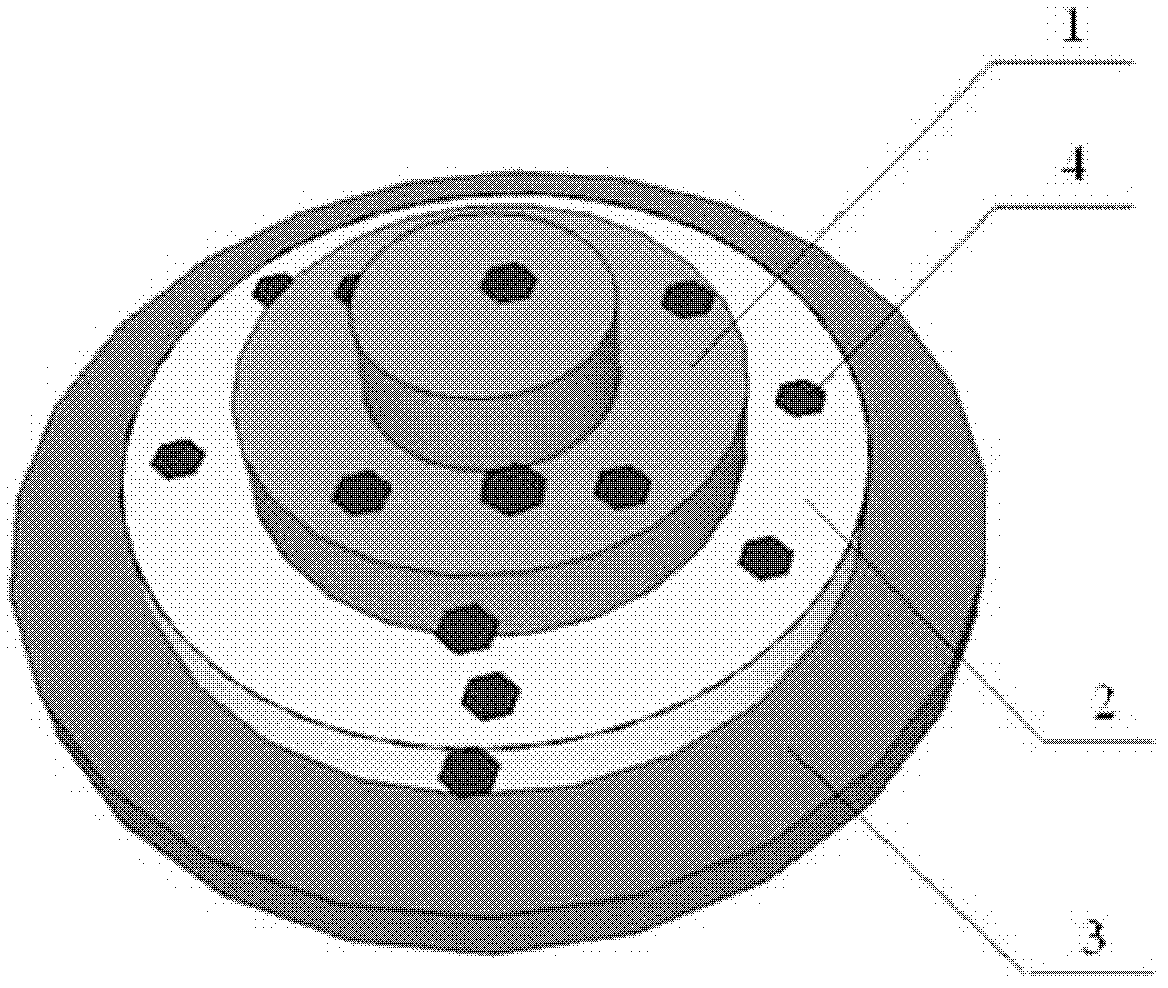

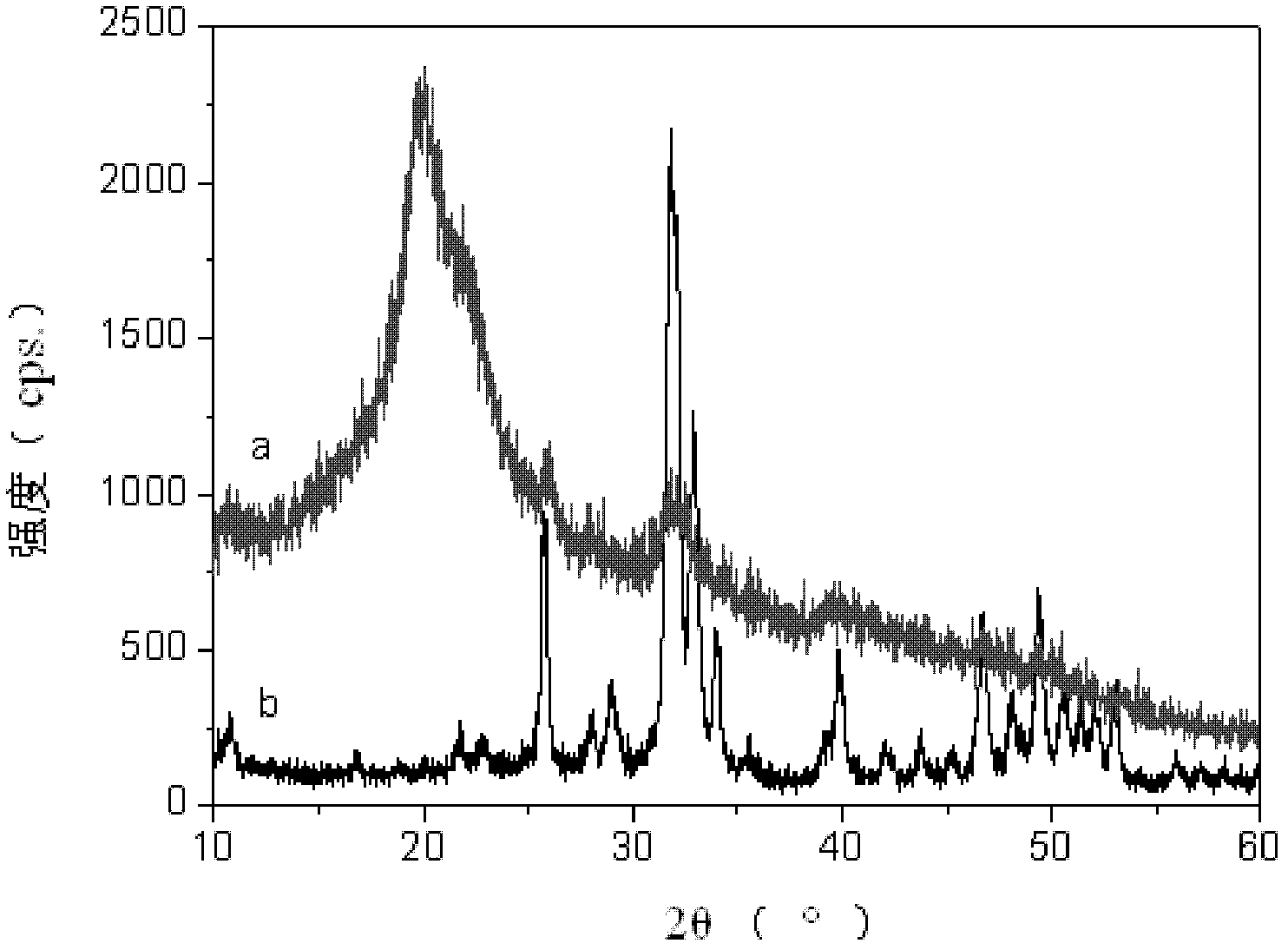

[0009] Specific embodiment one: the chitosan / apatite / rifampicin composite material of long-acting drug release is prepared by the biomimetic mineralization method of the present embodiment and is carried out according to the following steps: Acetic acid solution is used as a solvent, and a chitosan solution with a mass percentage concentration of 2% to 5% is prepared; 2. The chitosan solution prepared in step 1 is evenly applied to the inner surface of the capsule mold, and then soaked in the coagulation solution for 2 hours ~24h, after taking off the mould, a capsule-shaped chitosan hydrogel film is obtained; three, the chitosan solution prepared in step 1 is injected into the capsule-shaped chitosan hydrogel film prepared in step 2, and then the capsule-shaped chitosan water The gel film is first soaked in the coagulation solution for 1min to 20min, then soaked in the alcohol aqueous solution for 1min to 20min, repeats the alternate soaking operation for 120min, and then wash...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that the thickness of the capsular chitosan hydrogel film in step 2 is 0.2 mm to 0.6 mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the coagulation liquid described in step two is ammonia water with a mass percentage concentration of 5% to 10%, and a mass percentage concentration of 3% to 10% NaOH aqueous solution or an aqueous solution of KOH with a mass percent concentration of 3% to 10%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com