Porous magnesium alloy/biological ceramic bionic composite support and quick forming method thereof

A technology of bioceramics and composite scaffolds, applied in bone implants, medical science, prostheses, etc., can solve problems such as the mismatch between the strength degradation rate and the bone reconstruction process, insufficient mechanical strength and stability, etc., to achieve the solution of mechanical strength Insufficient stability and reduced contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

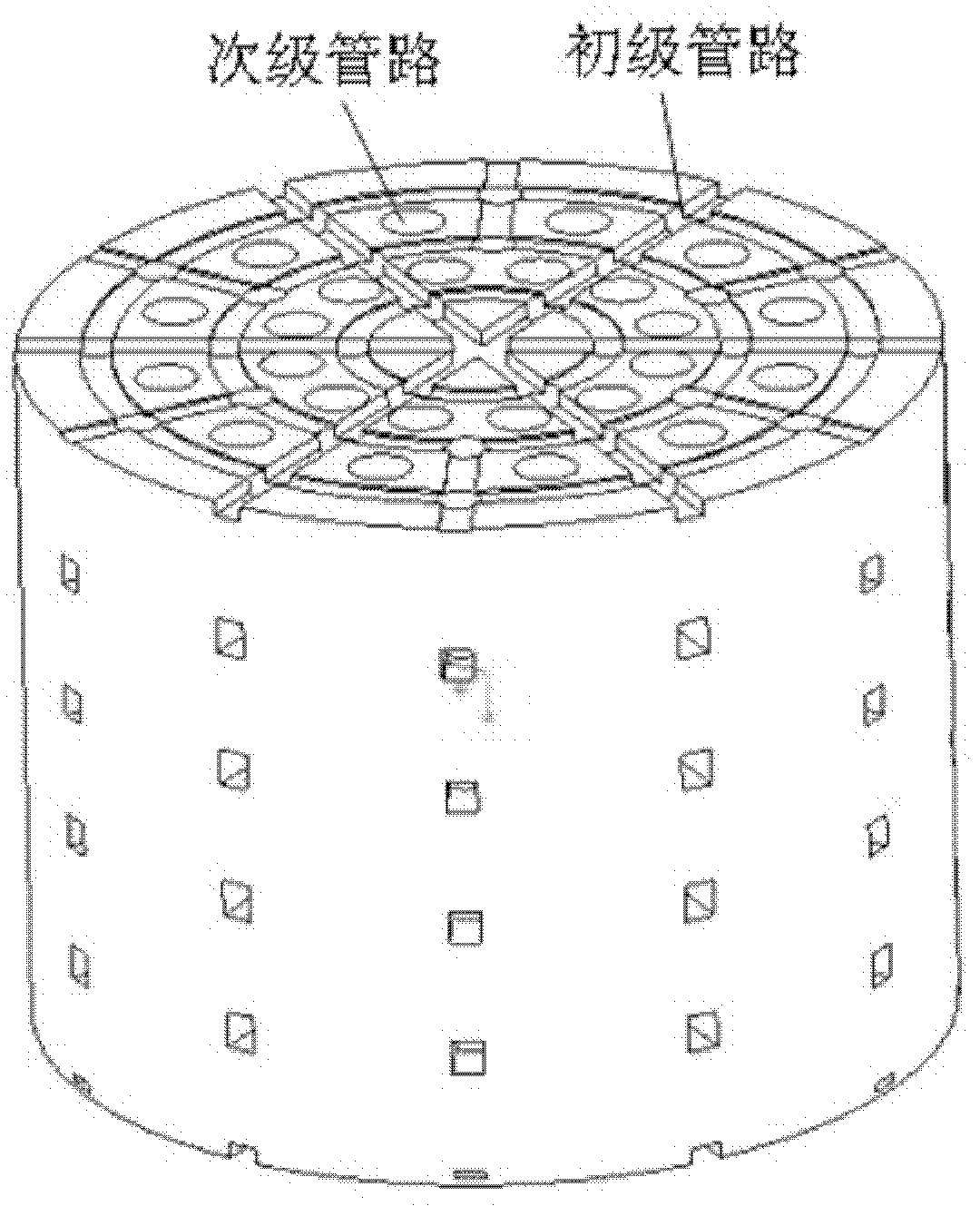

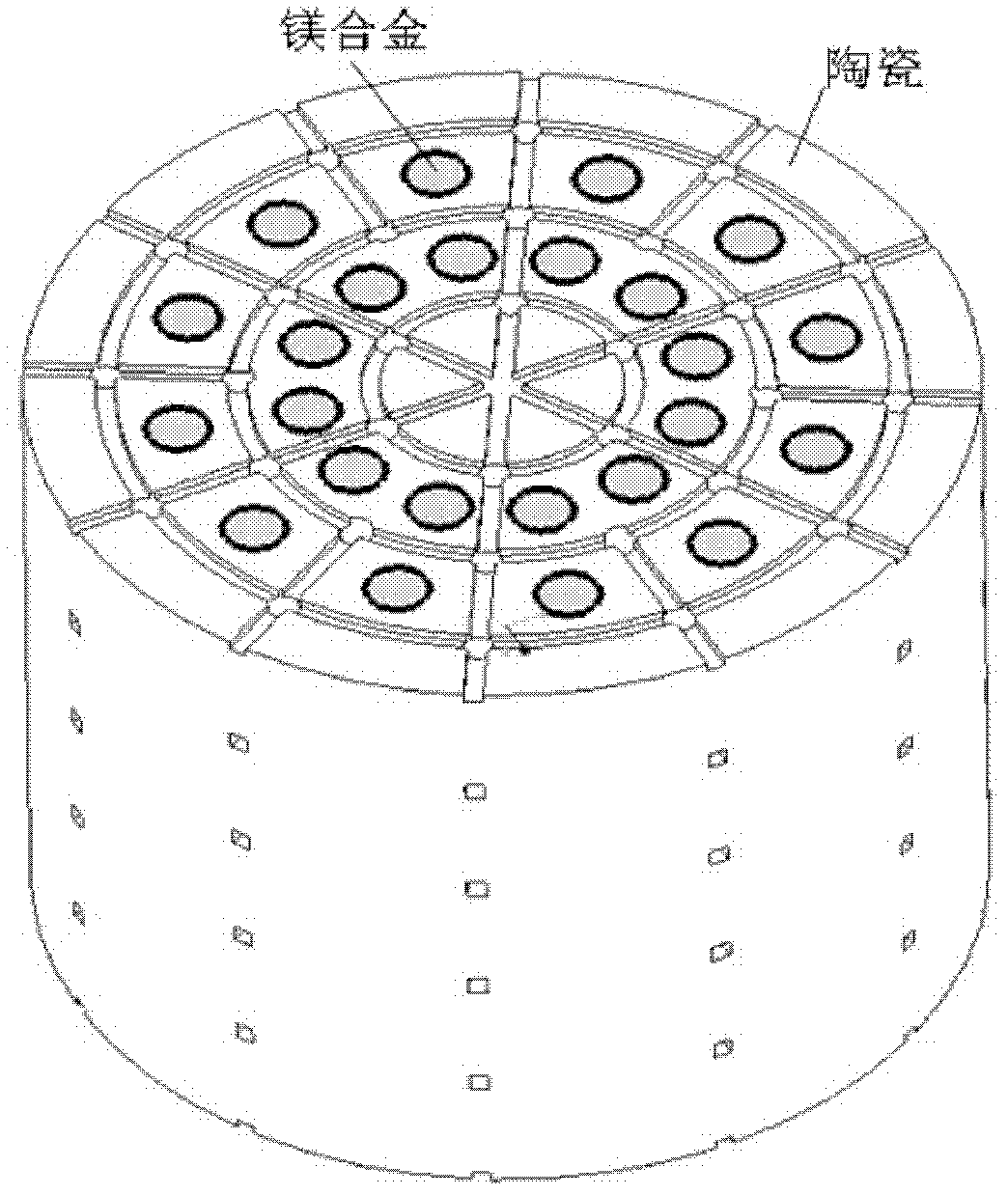

[0023] 1) First, according to the specific conditions of the patient's bone defect site, the shape correlation and microstructure bionic design of the bone defect site are carried out by means of reverse engineering and CAD technology, and the force, internal deformation and hydrodynamic properties of the stent are analyzed by CAE analysis software. The structure is modified to form a CAD model of the biomimetic scaffold with the internal microstructure of the primary and secondary two-stage pipelines that are not connected to each other;

[0024] 2) Mix deionized water, glycerin, organic monomer acrylamide, and crosslinking agent N,N-dimethylenebisacrylamide into a premix, wherein the quality of glycerin accounts for 20% of the total mass of the premix, and the organic monomer The mass ratio of crosslinking agent and monomer is 1:8, the balance is deionized water, and then the ceramic powder Beta-tricalcium phosphate (β-TCP) and dispersant polymer are added to the premix in ba...

Embodiment 2

[0028] Example 2: In this example, the bioceramic slurry was prepared by the following method, and other steps were the same as those in Example 1:

[0029] Mix deionized water, glycerin, organic monomer methyl-acyloxyethyl trimethyl ammonium chloride, and cross-linking agent N,N-diacetone acrylamide into a premix, wherein the mass of glycerol accounts for the total mass of the premix The mass ratio of crosslinking agent and monomer is 1:8, the balance is deionized water, and then the ceramic powder Alpha-tricalcium phosphate (α -TCP) and dispersant ammonium polyacrylate are prepared into ceramic slurry, wherein the volume ratio of ceramic powder to premix is 1:1, and the content of dispersant is 0.3% of the mass of ceramic powder, and then poured into a ball mill jar in a ball mill The ball mill was carried out for 2 hours, and the photoinitiator sodium persulfate with a mass of 1% of the mass of the premix solution was added, and the bioceramic slurry was obtained by furth...

Embodiment 3

[0030] Example 3: In this example, the bioceramic slurry was prepared by the following method, and other steps were the same as those in Example 1:

[0031] 2) Mix deionized water, glycerol, organic monomer adipic acid dihydrazide, and crosslinking agent dibenzylidene acetonyl acrylamide into a premix, wherein the quality of glycerol accounts for 20% of the total mass of the premix, and the organic monomer The mass of the body accounts for 26%, the mass ratio of crosslinking agent and monomer is 1:8, and the balance is deionized water. Then, ceramic powder apatite and dispersant sodium polyacrylate are added to the premix in batches to prepare ceramic slurry. The volume ratio of the ceramic powder to the volume of the premix is 1:1, the dispersant content is 0.3% of the mass of the ceramic powder, and then poured into a ball mill tank and ball-milled on a ball mill for 2 hours, and then added with a mass of 1% of the mass of the premix The photoinitiator potassium persulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com