Method for preparing sodium phosphate and barium chloride with cogeneration of powdery barium salt by using salting-out master liquid generated in zinc powder method

A sodium phosphate, zinc powder method technology, applied in chemical instruments and methods, thiosulfate/dithionite/polythionite, phosphorus compounds, etc., can solve the problem of low quality of recovered salt, secondary pollution, escaping and other problems, to achieve considerable economic benefits, pollution control, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

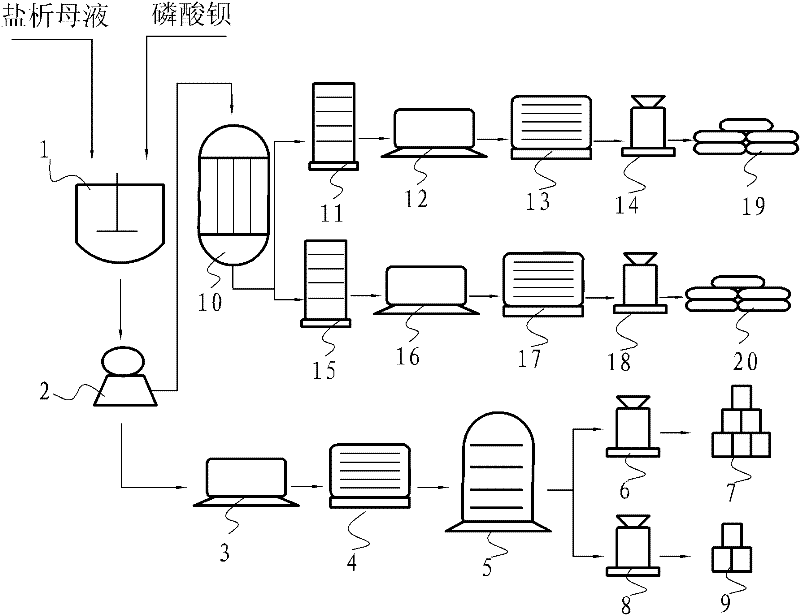

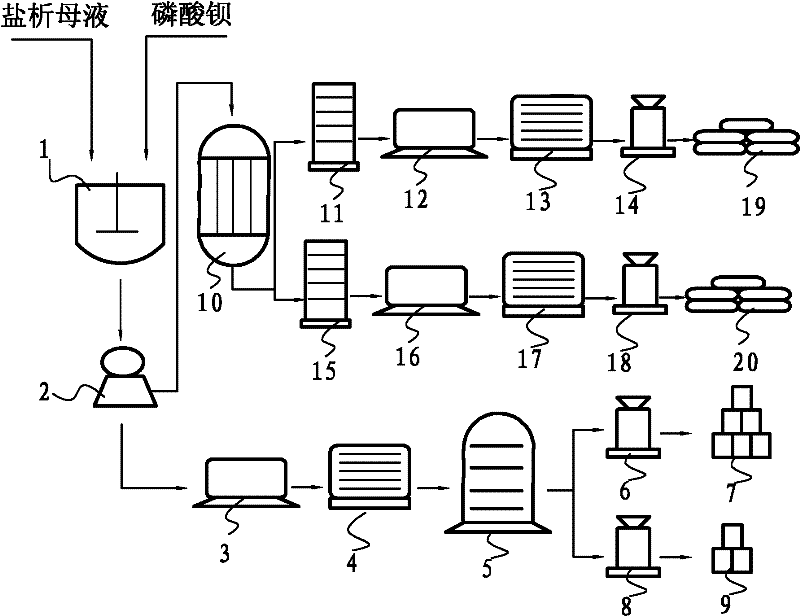

[0023] The method for preparing sodium phosphate and barium chloride co-production powder barium salt with the salting-out mother liquor in the zinc powder method comprises the following preparation steps:

[0024] Step A, put 1000 liters of salting-out mother liquor and barium phosphate solution in the zinc powder method into corrosion-resistant reactor 1 according to the mass ratio of pure substance 1: 0.95 (wherein containing 40Kg of sodium sulfite, 20Kg of sodium dithionite, sodium chloride 250Kg, calculated according to the mass ratio of sodium sulfite to barium phosphate 1:0.95, the mass ratio of sodium dithionite to barium phosphate 1:0.95, and the mass ratio of sodium chloride to barium phosphate 1:0.95, the required barium phosphate Be 294.5Kg), keep stirring; Reaction generates the mixed solution of sodium phosphate, barium chloride, barium sulfite barium dithionite;

[0025] Step B, filter the mixed solution obtained in step A with a filter 2;

[0026] Step C, with...

Embodiment 2

[0030] The method for preparing sodium phosphate and barium chloride co-production powder barium salt with the salting-out mother liquor in the zinc powder method comprises the following preparation steps:

[0031] Step A, put 1000 liters of salting-out mother liquor and barium phosphate solution in the zinc powder method into corrosion-resistant reactor 1 according to the mass ratio of pure substance 1: 1.71 (wherein containing sodium sulfite 40Kg, sodium dithionite 20Kg, sodium chloride 250Kg, calculated according to the mass ratio of sodium sulfite to barium phosphate 1:1.71, the mass ratio of sodium dithionite to barium phosphate 1:1.71, and the mass ratio of sodium chloride to barium phosphate 1:1.71, the required input chloride Barium is 530.1Kg), constantly stirring; Reaction generates the mixed solution of sodium phosphate, barium chloride, barium sulfite barium dithionite;

[0032] Step B, filter the mixed solution obtained in step A with a filter 2;

[0033] Step C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com