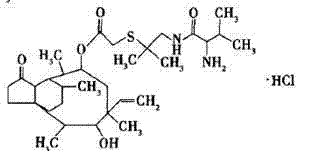

Method for purifying valnemulin hydrochloride

A technology of nemoline hydrochloride and its purification method, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as difficult purification of valnemulin hydrochloride, and achieve avoidance of re-extraction, Ease of waste water and less product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

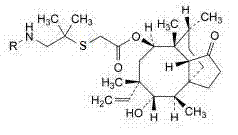

Image

Examples

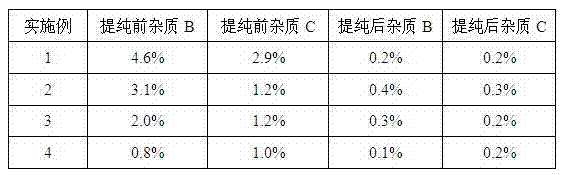

Embodiment 1

[0035] Accurately weigh 64.6 g of valnemulin hydrochloride with a content of 80% and dissolve it in 600 ml of water, add 600 ml of dichloromethane, adjust the pH to 8.2 with aqueous sodium hydroxide solution, let stand for layers, discard the water layer, and discard the organic layer After washing with 600ml of water, it was vacuum-dried. Add 200ml of methanol to the dried solid and dissolve it completely, then add 84.2g of 10% phosphoric acid, stir for 0.5h, evaporate to dryness, then add 100ml of methanol to dissolve again. To the obtained methanol solution, slowly add 1100ml of methyl tert-butyl ether dropwise under vigorous stirring and stir until the precipitation is complete, filter, wash the filter cake with a small amount of dichloromethane, and distill the filtrate to recover the solvent for reuse. Dissolve the filter cake with 1200ml of methyl tert-butyl ether / water mixed solution with a volume ratio of 1 / 1, adjust the pH to 7.2 with lye, let the layers stand and di...

Embodiment 2

[0037]Accurately weigh 80g of 85% valnemulin sulfate, dissolve it in 960ml of water, add 960ml of methyl tert-butyl ether, adjust the pH to 9.0 with potassium hydroxide aqueous solution, let it stand for stratification, discard the water layer, organic The layer was washed with 960 ml of water and vacuum-dried. Add 230ml of ethanol to the dry solid and dissolve it completely, add 50.2g of 20% phosphoric acid, stir for 0.5h, evaporate to dryness, then add 120ml of ethanol to redissolve. To the obtained ethanol solution, slowly add 1400ml of methyl tert-butyl ether dropwise under vigorous stirring and stir until the precipitation is complete, filter, and wash the filter cake with a small amount of methyl tert-butyl ether, and the filtrate is rectified to recover ether and methanol respectively reuse. Dissolve the filter cake with 1600ml of methyl tert-butyl ether / water mixed solution with a volume ratio of 1 / 1, adjust the pH to 8.0 with lye; let stand to separate layers, discar...

Embodiment 3

[0039] Accurately weigh 100 g of valnemulin tartrate with a content of 90% and dissolve it in 1000 ml of water, add 1000 ml of a mixed solvent of n-hexane and petroleum ether with a volume ratio of 1:1, adjust the pH to 8.0 with ammonia water, let stand and separate, The aqueous layer was discarded, and the organic layer was washed with 1000 ml of water and dried under reduced pressure. Add 400ml of methanol to the dried solid and dissolve it completely, then add 41.1g of 30% phosphoric acid, stir for 0.5h, evaporate to dryness, then add 100ml of methanol to dissolve again. To the resulting methanol solution, slowly add 1000ml of a mixed solution of n-hexane and petroleum ether with a volume ratio of 1:1 dropwise under vigorous stirring and stir until the precipitation is complete, filter, and wash the filter cake with a small amount of petroleum ether Recover solvent and methanol. Dissolve the filter cake with 2000ml of methyl tert-butyl ether / water mixed solution with a vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com