Two-layered flexible substrate, and copper electrolyte for producing same

A technology of flexible substrates and copper electrolytes, applied in the fields of printed circuit manufacturing, circuit substrate materials, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13、 comparative example 1~7

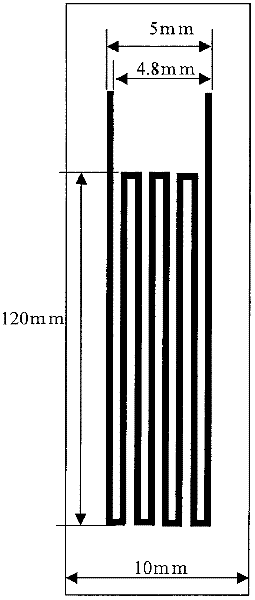

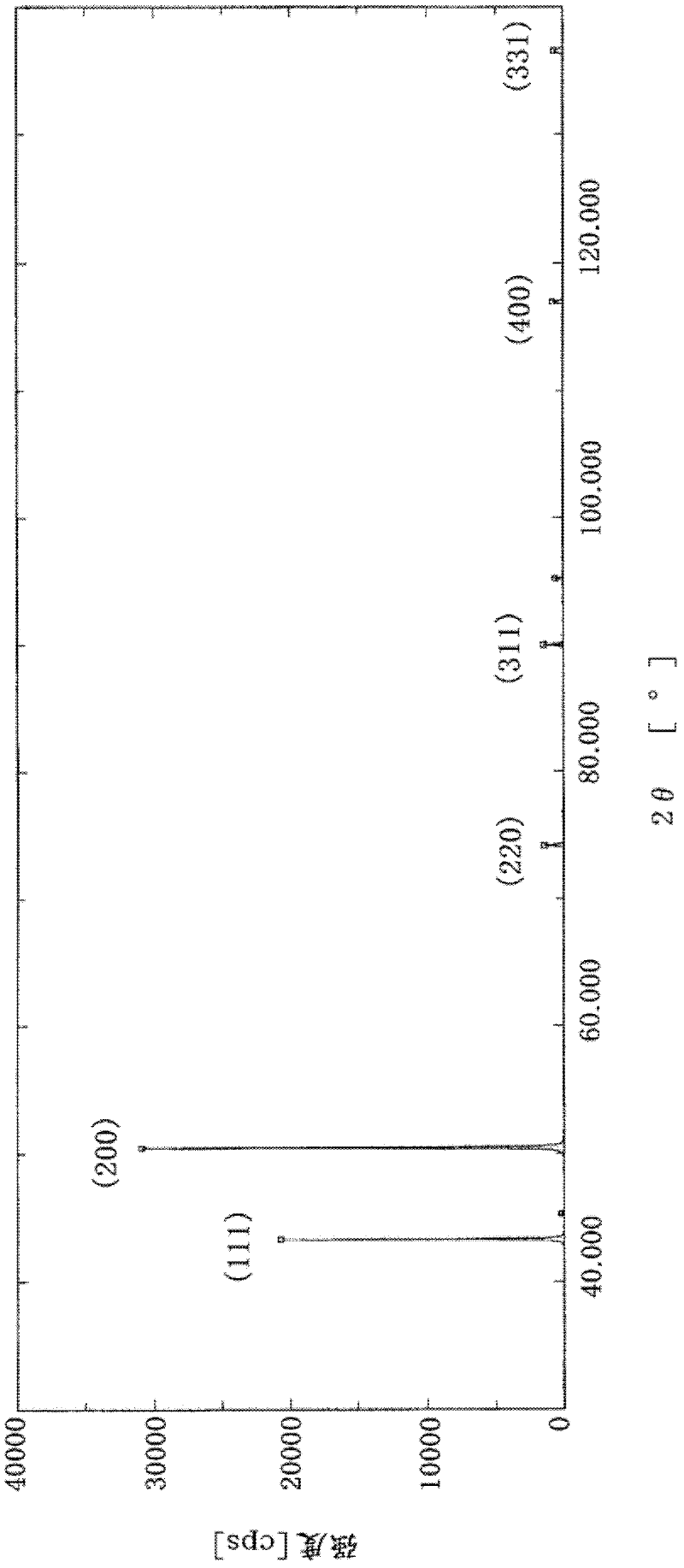

[0057] The additives were added to an aqueous solution prepared with copper sulfate and sulfuric acid to the following concentrations, and the polyimide film with the base metal layer was electroplated under the following plating conditions to produce a copper film of about 8 μm. The plating temperature is 40° C., and the additives and their addition amounts are listed in Table 1. In addition, in Table 1, the unit of the addition amount of an additive is ppm. Hydrochloric acid was used as the source of chloride ions.

[0058] Liquid capacity: 1700ml

[0059] Anode: lead electrode

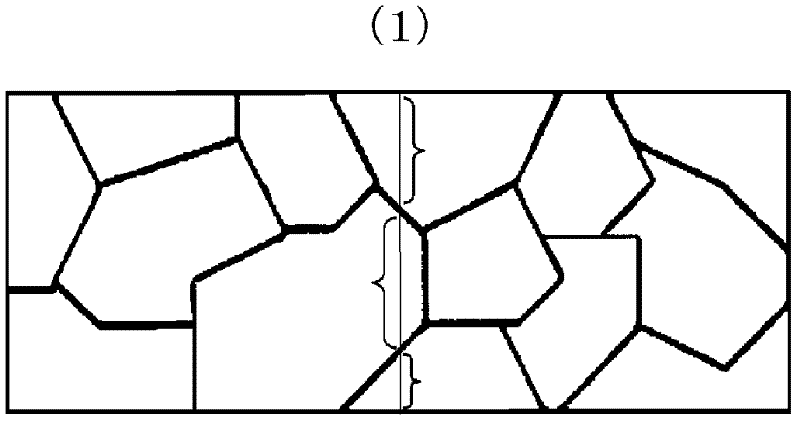

[0060] Cathode: a wound electrode formed by winding a polyimide film with a base metal layer

[0061] Polyimide film with base metal layer:

[0062] Formed on 37.5μm thick kapton E (manufactured by DuPont) Thick Ni-Cr, then sputtered to form 2000□ thick copper.

[0063] Current time: 2800As

[0064] Current density: 5→15→25→40A / dm 2 , hold each current density for 35 seconds in this order ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com