Adsorbent, preparation method and application thereof

A technology of adsorbent and microspheres, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of small capacity, cumbersome pretreatment process, low reuse rate, etc. Achieve the effect of high industrial use value, good reusability and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

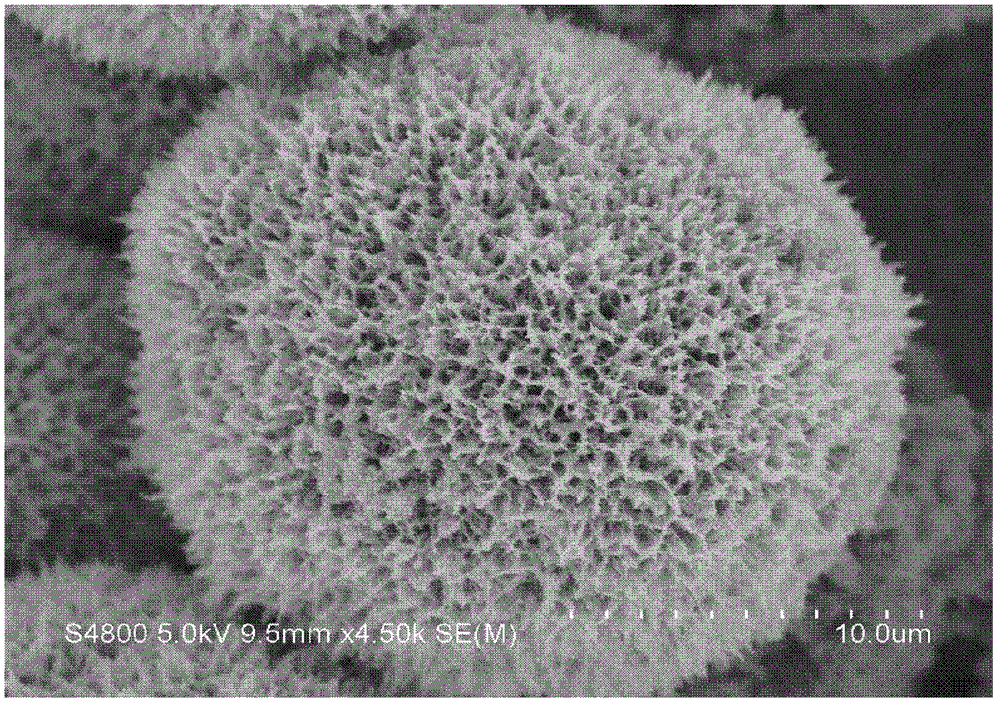

[0029] 0.1 g of urea CO(NH 2 ) 2 , 1mmol of ferric chloride and 4mmol of sodium hydrogen phosphate, dissolved in 20 milliliters of water, vigorously stirred, after mixing evenly, poured the resulting mixed solution into 25 milliliters of polytetrafluoroethylene as a lining stainless steel autoclave, heated to 160 °C for 12 hours. After the reaction, the autoclave was cooled to room temperature, and the light yellow product was washed alternately with absolute ethanol and deionized water several times, and dried at 60°C in a vacuum oven, as image 3 As shown, the obtained product has porous iron oxyphosphate microspheres adsorbing dyes and heavy metal ions, and its appearance is honeycomb porous microspheres, and its particle size is 18-25 microns.

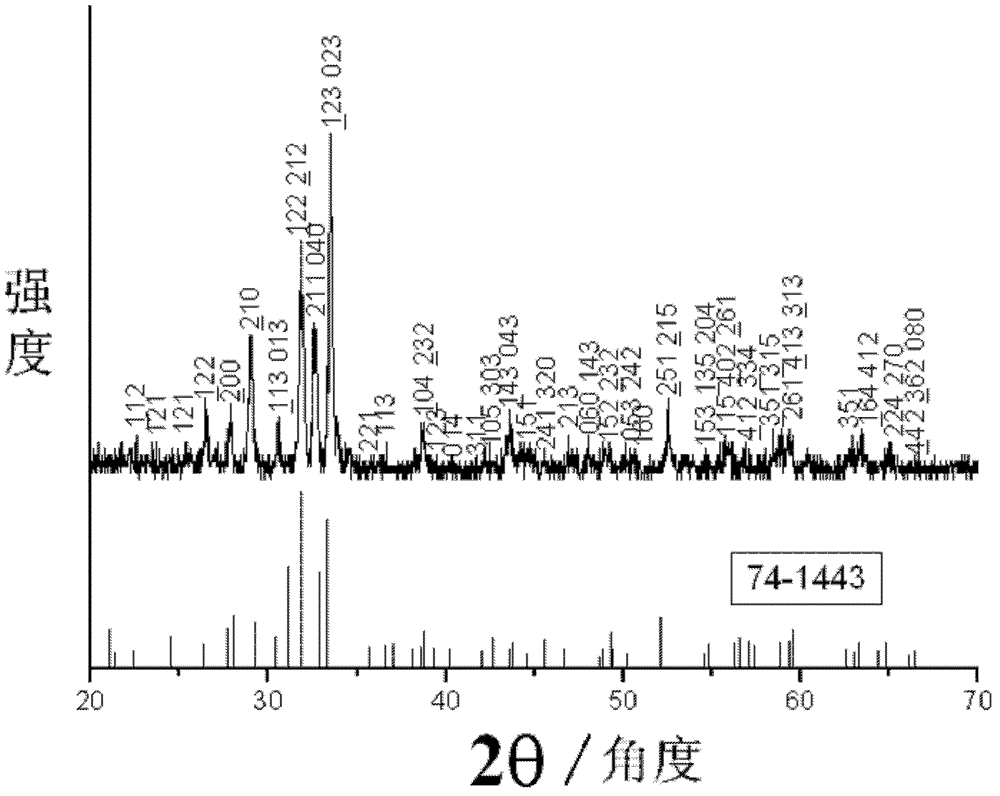

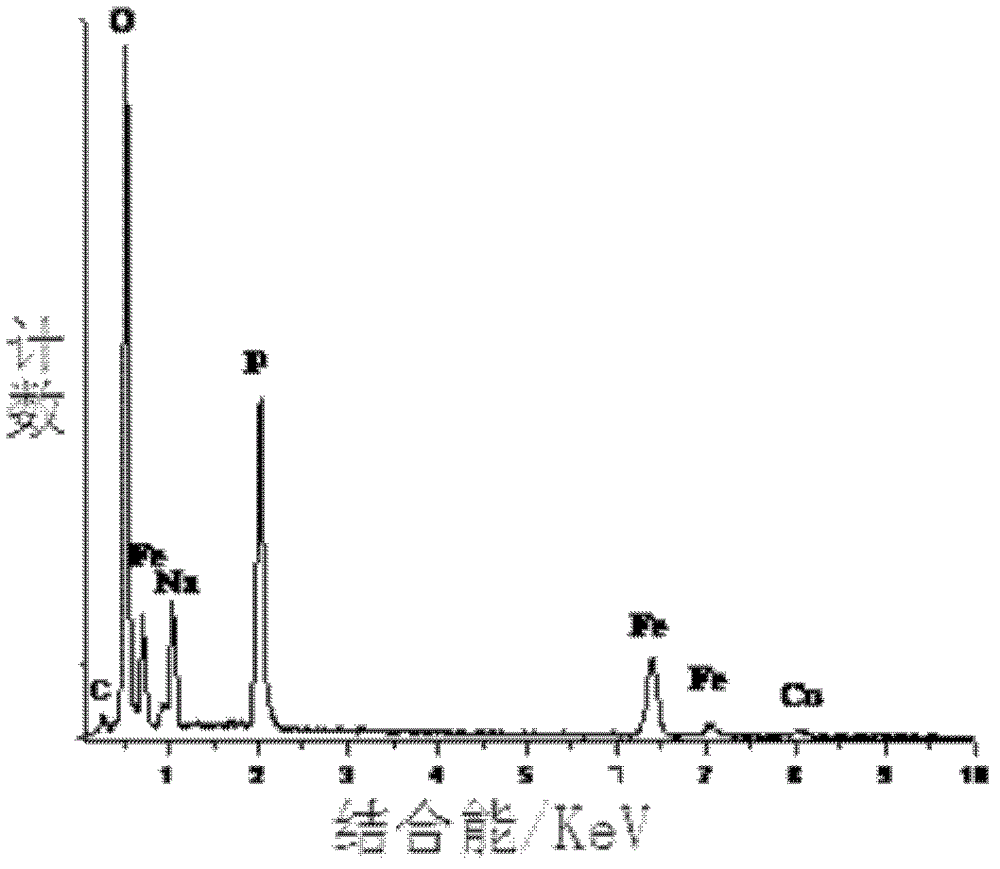

[0030] The product (Cu Kα ray, λ=0.154060 nm, scan speed 0.02 o / s) for phase identification, such as figure 1 shown in . Compared with the JCPDS standard card (74-1443), all diffraction peaks are related to Fe 4 (PO 4 ) 2 ...

Embodiment 2

[0032] 0.1 g of urea CO(NH 2 ) 2 , 1mmol of ferric sulfate and 4mmol of sodium hydrogen phosphate, dissolved in 20ml of water, vigorously stirred, after mixing evenly, pour the resulting mixed solution into 25ml of polytetrafluoroethylene as a stainless steel autoclave lined, heated to 160 ℃ for reaction 12 hours. After the reaction, the autoclave was cooled to room temperature, and the light yellow product was washed alternately with absolute ethanol and deionized water several times, and dried at 60°C in a vacuum oven, as Figure 4 As shown, the obtained product also has porous iron oxyphosphate microspheres adsorbing dyes and heavy metal ions, and its appearance is honeycomb porous microspheres composed of flakes.

Embodiment 3

[0034] 0.1 g of urea CO(NH 2 ) 2 , 1mmol of ferric nitrate and 4mmol of sodium hydrogen phosphate, dissolved in 20ml of water, vigorously stirred, after mixing evenly, pour the resulting mixed solution into 25ml of Teflon-lined stainless steel autoclave, heated to 160°C for reaction 12 hours. After the reaction, the autoclave was cooled to room temperature, and the light yellow product was washed alternately with absolute ethanol and deionized water several times, and dried at 60°C in a vacuum oven, as Figure 5 As shown, the obtained product also has porous iron oxyphosphate microspheres adsorbing dyes and heavy metal ions, and its appearance is honeycomb porous microspheres composed of flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com