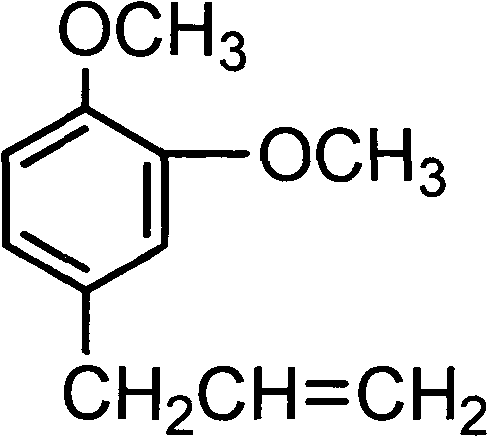

Synthesis method of eugenol methyl ether

A technology for synthesizing eugenol methyl ether, which is applied in the fields of ether preparation, ester reaction to ether, organic chemistry, etc., can solve problems such as environmental pollution, and achieve the effects of non-toxic raw materials, less corrosive equipment, and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

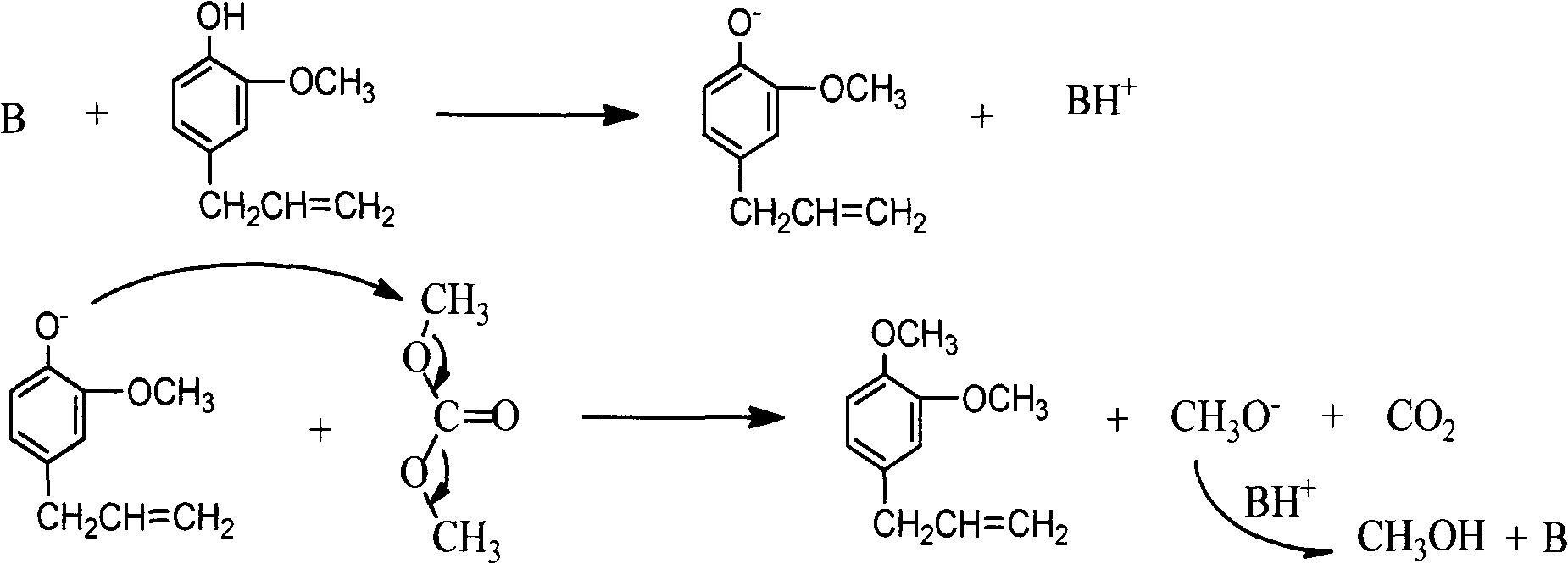

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 50 g (0.3 mol) of eugenol, 40.5 g (0.45 mol) of DMC and 12 g of KF catalyst with a content of 98.5% respectively in the tank-type gas-liquid reaction experimental device equipped with thermocouple, pressure gauge and electromagnetic stirring, and fill with nitrogen , pressurized to 0.25MPa. Heating while stirring, at 200°C, add 27g (0.3mol) DMC to the reaction kettle with a plunger pump at a rate of 0.45g / min, react for 3 hours, stop heating, and end the reaction. Pass cooling water down to room temperature, open the back pressure valve to vent until the equipment is at normal pressure, and release the material from the bottom of the reactor. The solid alkali catalyst was separated by filtration, the product was adjusted to neutral with dilute hydrochloric acid, 40mL of toluene was added, and the lower layer liquid was separated after standing; the organic phase was washed 3 times with 30mL distilled water, and the aqueous phase was combined, extracted with 20mL×2 t...

Embodiment 2

[0028] Add 50 g (0.3 mol) of eugenol, 40.5 g (0.45 mol) of DMC, and 40.5 g (0.45 mol) of DMC, respectively, in a tank-type gas-liquid reaction experimental device equipped with a thermocouple, a pressure gauge, and an electromagnetic stirrer with a content of 98.5%. 3 Catalyst 12g, filled with nitrogen, pressurized to 0.25MPa; heated to raise the temperature under stirring, at 200°C, add 27g (0.3mol) DMC to the reaction kettle with a plunger pump at a speed of 0.45g / min, and react for 3 hours After a period of time, stop heating and end the reaction; feed cooling water down to room temperature, open the back pressure valve to vent until the equipment is at normal pressure, and discharge the material from the bottom of the reactor; filter and separate the solid alkali catalyst, and adjust the product to neutral with dilute hydrochloric acid 40mL toluene was added, and the lower layer liquid was separated after standing; the organic phase was washed 3 times with 30mL distilled wa...

Embodiment 3

[0030]Add 50 g (0.3 mol) of eugenol, 40.5 g (0.45 mol) of DMC and 12 g of KOH catalyst with a content of 98.5% respectively in a kettle-type gas-liquid reaction experimental device equipped with thermocouple, pressure gauge and electromagnetic stirring, and fill with nitrogen , pressurize to 0.25MPa; heat and heat up under stirring, at 200°C, add 27g (0.3mol) DMC to the reaction kettle with a plunger pump at a speed of 0.45g / min, react for 3 hours, stop heating, End the reaction; feed cooling water down to room temperature, open the back pressure valve to vent until the equipment is at normal pressure, and discharge the material from the bottom of the reactor; filter and separate the solid alkali catalyst, and the product is adjusted to neutral with dilute hydrochloric acid, and 40 mL of toluene is added. After standing still, the lower layer was separated; the organic phase was washed 3 times with 30 mL of distilled water, the aqueous phase was combined, extracted with 20 mL×2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com